Cut stems for cigarettes and preparation method thereof as well as cigarettes

A technology for cut stems and tobacco, applied in the field of cut tobacco stems and their preparation, can solve the problems of cigarette weight, large fluctuation in suction resistance, easy to be distinguished, large difference between shape and cut tobacco, etc., to improve equipment capacity Bottleneck, improve sensory quality, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

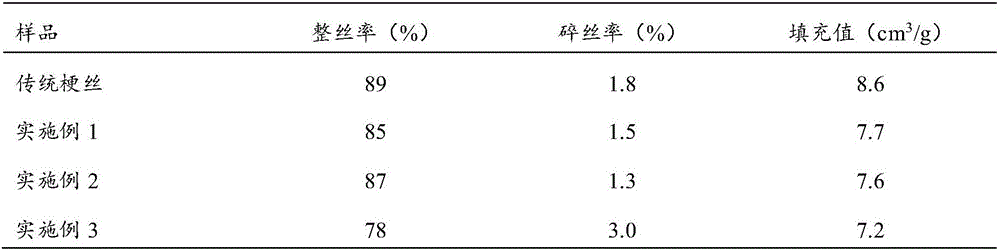

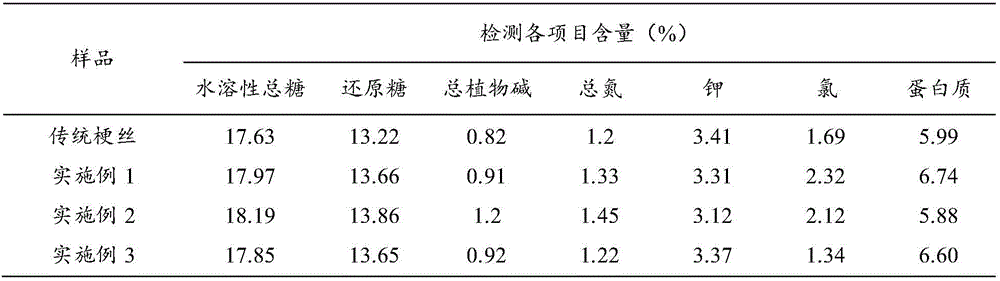

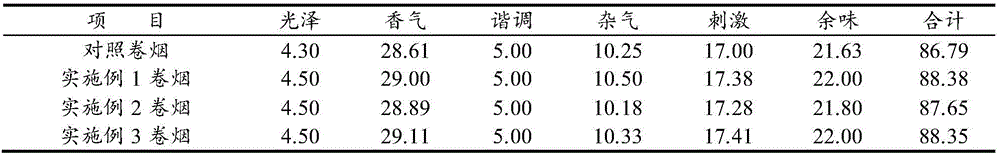

[0044] The preparation of embodiment 1 cut stems for tobacco

[0045] Take a mixture of 1000kg of tobacco stems, screen them, expand them with microwaves, and control the expansion rate at 30%, wash the stems with warm water at 55°C (the water velocity is 0.70m / s, and the frequency of the bottom band is 18Hz), and then enter the pressure wet stems, The steam pressure is controlled at 0.15MPa, and the moisture is controlled at 32%.

[0046] The tobacco stems after pressure moistening are pressed, the gap between the pressing rollers is set at ≤0.7mm, and the stems are directly cut into shredded stems with a width of 0.07mm, and then the shredded stems are added with spices. %, store the stems in a cache cabinet (at a temperature of 26° C. and a humidity of 50%) for 1.5 hours.

[0047] Then, the tube-sheet drum-type silk drying is adopted, the hot air temperature is 110°C, the cylinder wall temperature is 120°C, the outlet temperature is 50°C, the rotating speed is 35Hz, and th...

Embodiment 2

[0049] The preparation of embodiment 2 cut stems for tobacco

[0050] Take a mixture of 1000kg of tobacco stems, screen them, expand them with microwaves, and control the expansion rate at 20%, wash the stems with warm water at 60°C (the water flow rate is 0.65m / s, and the frequency of the bottom belt is 20Hz), and then enter the pressure wet stems, The steam pressure is controlled at 0.10MPa, and the moisture is controlled at 30%.

[0051] The tobacco stems after pressure moistening are pressed, and the gap between the pressing rollers is set as: ≤0.7mm, and the stems are directly cut into shredded stems with a width of 0.08mm, and then the shredded stems are added. %, store the stems in a cache cabinet (at a temperature of 26°C and a humidity of 50%) for 1.0h.

[0052] Then, the tube-sheet drum-type silk drying is adopted, the hot air temperature is 112°C, the cylinder wall temperature is 135°C, the outlet temperature is 55°C, the rotating speed is 30Hz, and the flow rate i...

Embodiment 3

[0054] Embodiment 3 Preparation of shredded tobacco stems

[0055] Take a mixture of 1000kg of tobacco stems, screen them, expand them with microwaves, and control the expansion rate at 50%, wash the stems with warm water at 50°C (the water velocity is 0.75m / s, and the frequency of the bottom band is 15Hz), and then enter the pressure wet stems, The steam pressure is controlled at 0.20MPa, and the moisture is controlled at 35%.

[0056] The tobacco stems after pressure moistening are pressed, the gap between the pressing rollers is set at ≤0.7mm, and the stems are directly cut into shredded stems with a width of 0.06mm, and then the shredded stems are added with spices. %, store the stems in a cache cabinet (at a temperature of 26° C. and a humidity of 50%) for 2 hours.

[0057] Then, the tube-sheet drum-type silk drying is adopted, the hot air temperature is 115°C, the cylinder wall temperature is 130°C, the outlet temperature is 60°C, the rotating speed is 25Hz, and the flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com