Prefabricated reinforced concrete column and column splice joint with sleeves

A reinforced concrete column, prefabricated technology, applied in structural elements, building components, building reinforcements, etc., can solve the problems of low degree of industrialization, material loss and large amount of construction waste, extensive design and construction, etc., so as to reduce the number of binding steel bars. Work with supporting formwork, superior energy consumption and ductility, and low cost of repair and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

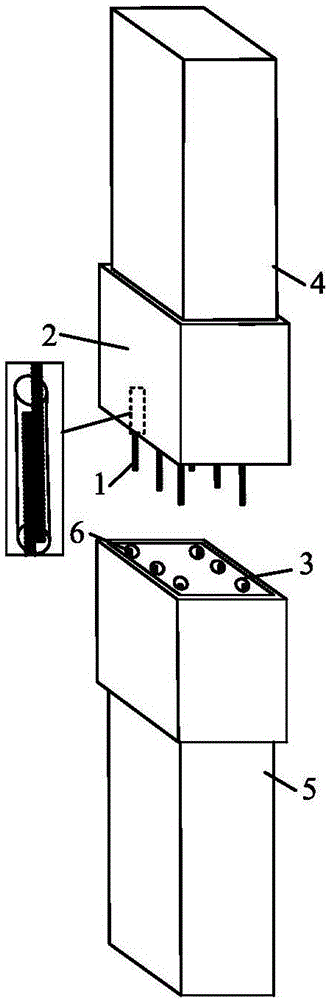

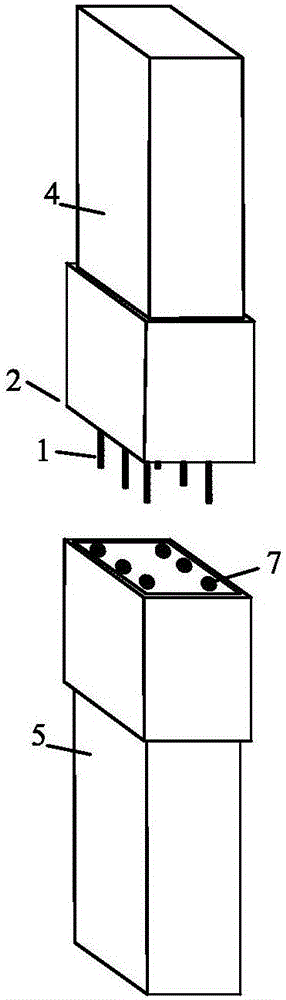

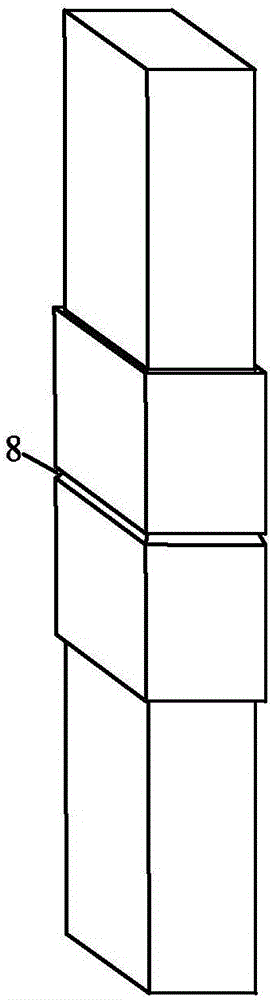

[0030] Specifically, the technical solution of the present invention is to provide a splicing joint between a prefabricated reinforced concrete column and a column that can be quickly assembled. The main components of the structural system include high-strength steel bars 1, steel sleeves 2, pre-embedded Column 4 and lower column 5. The installation method of structure of the present invention is:

[0031] 1. In addition to the grouting 7 of the inner corrugated casing 3 of the reinforced concrete lower column 5, the insertion of the high-strength steel bar 1 of the reinforced concrete upper column 4 and the groove welding 9 of the groove 8 of the connection part of the steel casing 2, all components are in the Factory prefabrication is completed, among which the pre-embedded high-strength steel bars 1 and corrugated casing 3 should meet the specifications and construction requirements. The pre-embedded corrugated sleeve 3 is fixed in place together with the longitudinal rein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com