High-efficiency extraction and separation method of grape seed proanthocyanidin oligomer

A technology of proanthocyanidin and separation method, which is applied in the field of efficient extraction and separation of grape seed proanthocyanidin oligomers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The method for efficiently extracting and separating grape seed proanthocyanidin oligomers comprises the following steps:

[0040] (1) Low-temperature drying and crushing: first, the grape seeds are dried at a low temperature at a temperature of 30°C and a vacuum of 0.06Mpa; then crushed to obtain 40 mesh grape seed powder, wherein the grape seeds are unfermented white grape seeds;

[0041] (2) Degreasing: The obtained grape seed powder is extracted with supercritical carbon dioxide to extract grape seed oil to remove grease at low temperature to obtain defatted grape seed powder, wherein the extraction pressure of supercritical carbon dioxide extraction is 32.30 MPa, and the extraction temperature is 41.5 ° C; the extraction time is 75 minutes; the final oil yield was 16.0%, and the residual oil yield was 0.2% to 0.5%.

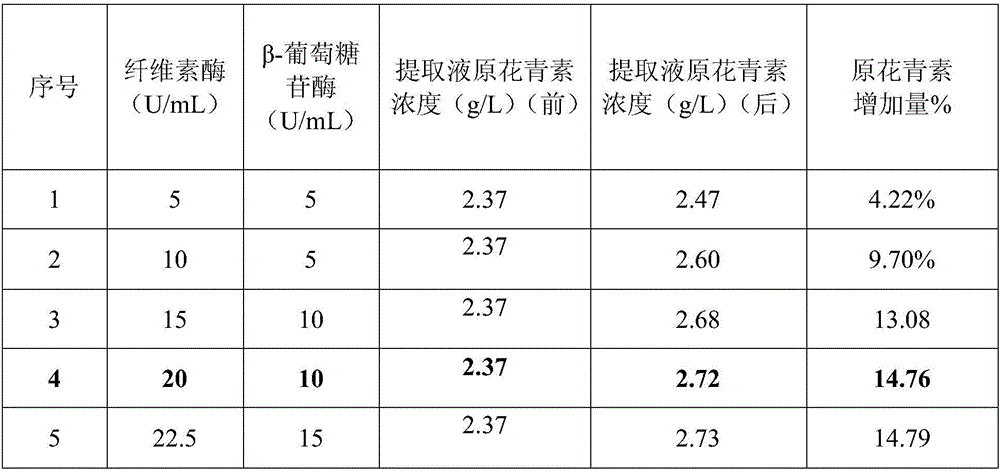

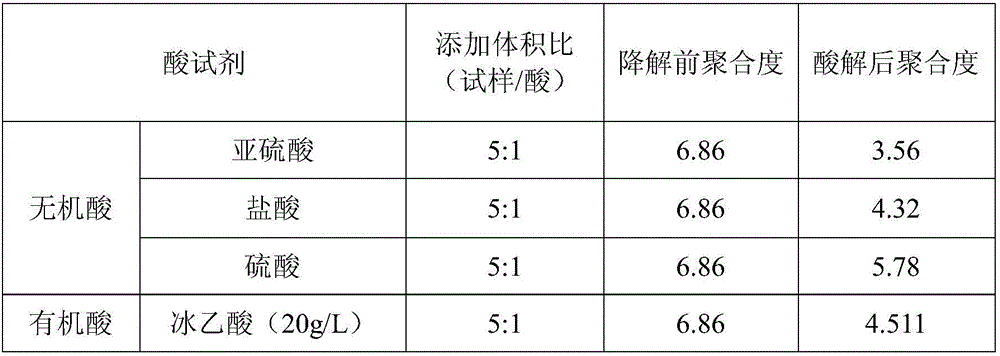

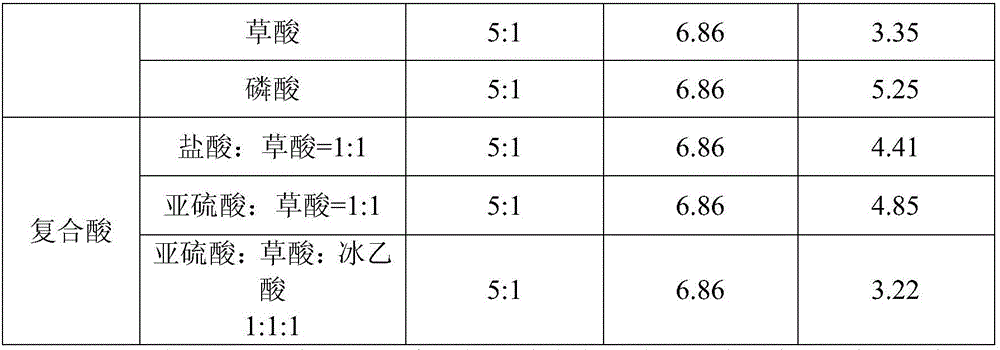

[0042] (3) Enzyme treatment: use cellulase and β-glucosidase to carry out biological enzyme treatment on the obtained defatted grape seed powder: take t...

Embodiment 2

[0049] The method for efficiently extracting and separating grape seed proanthocyanidin oligomers comprises the following steps:

[0050] (1) Low-temperature drying and crushing: first, the grape seeds are dried at a low temperature at a temperature of 50°C and a vacuum of 0.09 MPa; then crushed to obtain 60-mesh grape seed powder, wherein the grape seeds are unfermented white grape seeds;

[0051] (2) Degreasing: The obtained grape seed powder is extracted with supercritical carbon dioxide to extract grape seed oil to remove grease at low temperature to obtain defatted grape seed powder, wherein the extraction pressure of supercritical carbon dioxide extraction is 32.30 MPa, and the extraction temperature is 41.5 ° C; the extraction time is 75 minutes; the final oil yield was 16.0%, and the residual oil yield was 0.2% to 0.5%.

[0052] (3) Enzyme treatment: use cellulase and β-glucosidase to carry out biological enzyme treatment on the obtained defatted grape seed powder: tak...

Embodiment 3

[0059] The method for efficiently extracting and separating grape seed proanthocyanidin oligomers comprises the following steps:

[0060] (1) Low-temperature drying and crushing: first, the grape seeds are dried at a low temperature at a temperature of 45°C and a vacuum of 0.07 MPa; then crushed to obtain 40-60 mesh grape seed powder, wherein the grape seeds are unfermented white grape seeds;

[0061] (2) Degreasing: The obtained grape seed powder is extracted with supercritical carbon dioxide to extract grape seed oil to remove grease at low temperature to obtain defatted grape seed powder, wherein the extraction pressure of supercritical carbon dioxide extraction is 32.30 MPa, and the extraction temperature is 41.5 ° C; the extraction time is 75 minutes; the final oil yield was 16.0%, and the residual oil yield was 0.2% to 0.5%.

[0062] (3) Enzyme treatment: use cellulase and β-glucosidase to carry out biological enzyme treatment on the obtained defatted grape seed powder: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com