A kind of liquid absorbent for removing hydrogen sulfide and its application

A technology of liquid absorbent and hydrogen sulfide, applied in the direction of gas fuel, chemical instruments and methods, separation methods, etc., can solve the problems of increasing the preparation process of oxazolidine compounds, no research on wellbore effect, poor water solubility, etc., to prevent air pollution Environment, high selectivity, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

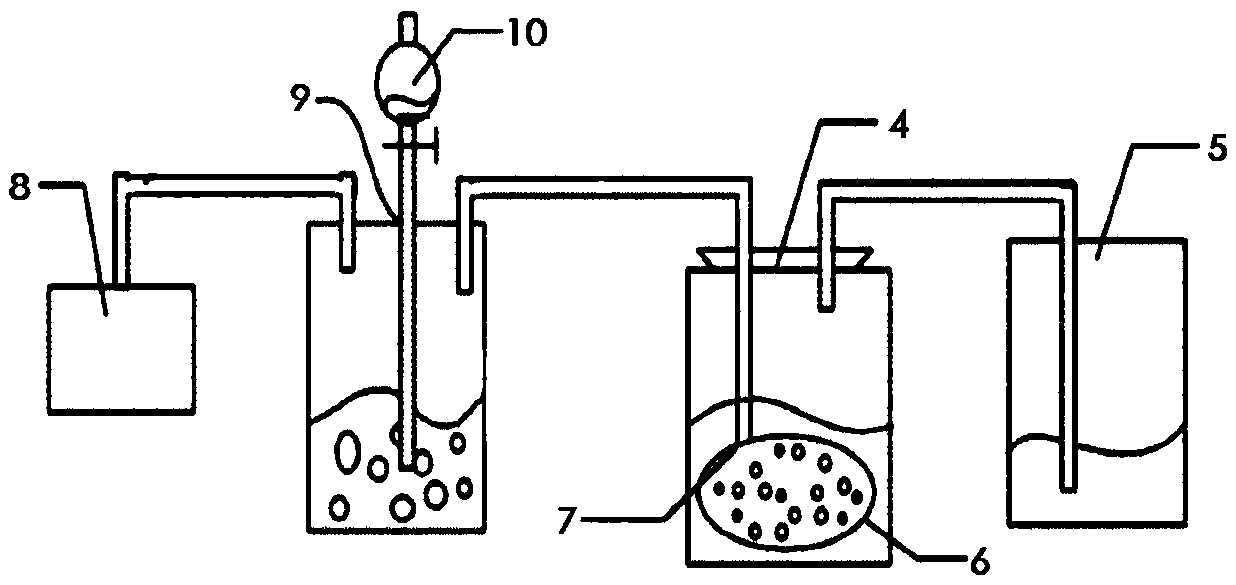

[0020] The liquid absorbent used in this embodiment for removing hydrogen sulfide consists of the following components in weight percent: 30% mixture of hexahydrotriazine compounds and pyridine compounds, 20% acetonitrile, 50% water, of which hexahydrotriazine The weight ratio of the oxazine compound to the pyridine compound is 1:1.

[0021] The specific preparation process is: put 15g of hexahydrotriazine compounds (10g of hydroxyethylhexahydro-s-triazine, 5g of 1,3,5-trimethylhexahydro-s-triazine) into a 500mL three-necked flask, and then add 15g Pyridine compounds (pyridine 5g, 2-picoline 10g) and 20g acetonitrile, after stirring for 10 minutes, add 50g of water, continue stirring for 10 minutes and mix well to obtain the product.

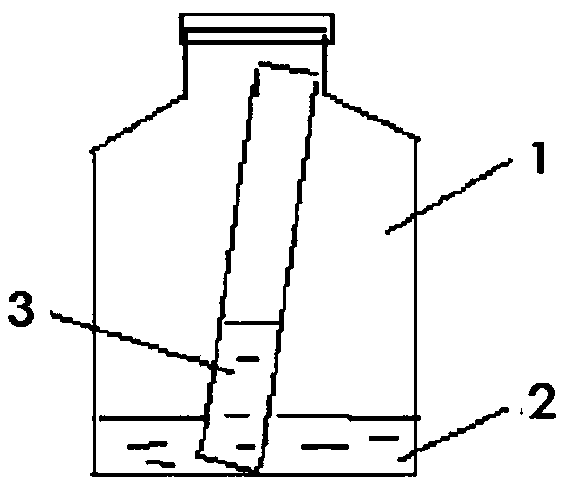

[0022] The liquid absorbent for removing hydrogen sulfide prepared in this example is applied to a wellbore containing sulfur.

Embodiment 2

[0024] The liquid absorbent used in this embodiment for removing hydrogen sulfide consists of the following components in weight percent: 30% mixture of hexahydrotriazine compounds and pyridine compounds, 20% acetonitrile, 50% water, of which hexahydrotriazine The weight ratio of the oxazine compound to the pyridine compound is 3:2.

[0025] The specific preparation process is as follows: put 18g of hexahydrotriazine compounds (10g of hydroxyethylhexahydro-s-triazine, 8g of 1,3,5-tris(3-methoxypropyl)-s-triazine into a 500mL three-necked flask ), then add 12g of pyridine compounds (pyridine 4g, 2-picoline 4g, 4-picoline 4g) and 20g of acetonitrile, after stirring for 10min, add 50g of water, continue to stir for 10min and mix well to obtain.

[0026] The liquid absorbent for removing hydrogen sulfide prepared in this example is applied to a wellbore containing sulfur.

Embodiment 3

[0028] The liquid absorbent used in this embodiment for removing hydrogen sulfide consists of the following components in weight percent: 30% mixture of hexahydrotriazine compounds and pyridine compounds, 20% acetonitrile, 50% water, of which hexahydrotriazine The weight ratio of the oxazine compound to the pyridine compound is 7:3.

[0029] The specific preparation process is: put 21g of hexahydrotriazine compounds in a 500mL three-necked flask (10g of hydroxyethylhexahydro-s-triazine, 5g of 1,3,5-trimethylhexahydro-s-triazine, 2-methyl -4-amino-6-methoxy-1,3,5-triazine 6g), then add 9g pyridine compounds (4-picoline 3g, 2-hydroxypyridine 3g, 2-hydroxyethylpyridine 3g) and 20g of acetonitrile, after stirring for 10min, add 50g of water, continue to stir for 10min and mix well to obtain.

[0030] The liquid absorbent for removing hydrogen sulfide prepared in this example is applied to a wellbore containing sulfur.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com