Method for preparing peanut shell activated carbon-based magnetic Cr(VI) adsorbent

A magnetic adsorbent and activated carbon technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve the problems of unstable adsorption performance, easy to block the gaps of activated carbon, etc., and achieve easy Magnetic separation, good cycle regeneration adsorption performance, and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

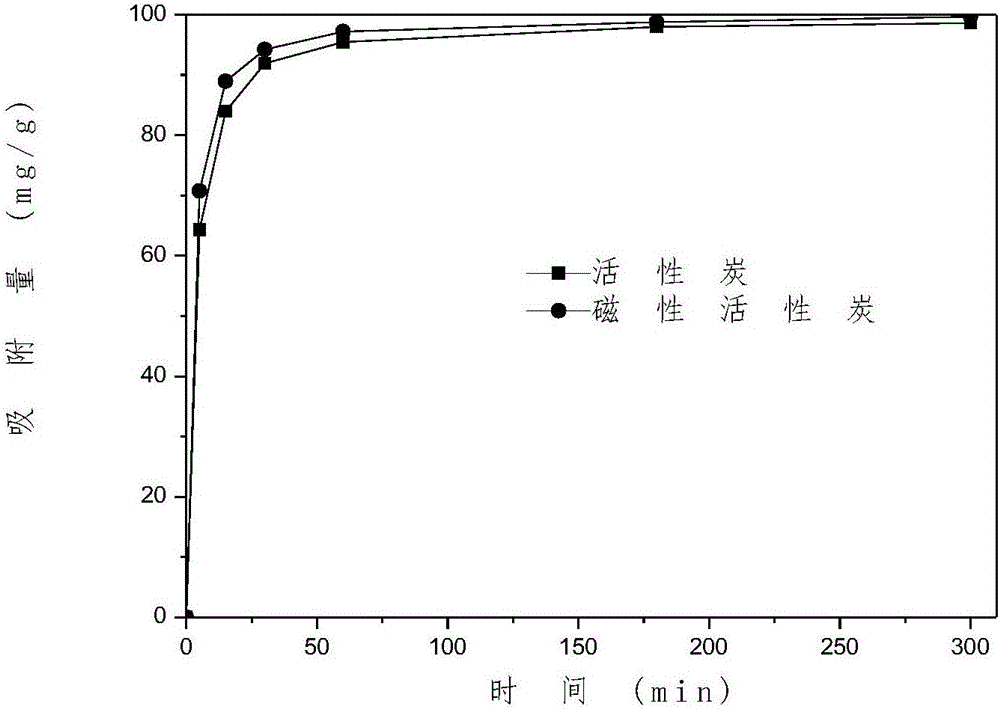

Embodiment 1

[0028] (1) Preparation of peanut shell activated carbon-based magnetic Cr(VI) adsorbent

[0029] Wash 5g of peanut shells with deionized water, dry in an oven at 100°C for 12h, and grind to 20-40 mesh. 2 Under the atmosphere, the heating rate was 5°C / min to 400°C, and the charred product was obtained after roasting at this temperature for 4 hours; then the charred product was dispersed in 28ml deionized water, and 6.2152g KOH was added, and after static immersion at room temperature for 12h Dry at 120°C for 12h, after grinding in N 2 Under the atmosphere, after 5°C / min, roast at 800°C for 30min, then wash the roasted activated product and dry it in vacuum at 60°C to obtain the peanut shell activated carbon sample.

[0030] Dissolve 0.1622g of ferric chloride hexahydrate in 60ml of ethylene glycol, add 0.4307g of anhydrous sodium acetate and stir for 30min, add 0.24g of peanut shell activated carbon sample, continue stirring at room temperature for 30min, then heat in water at...

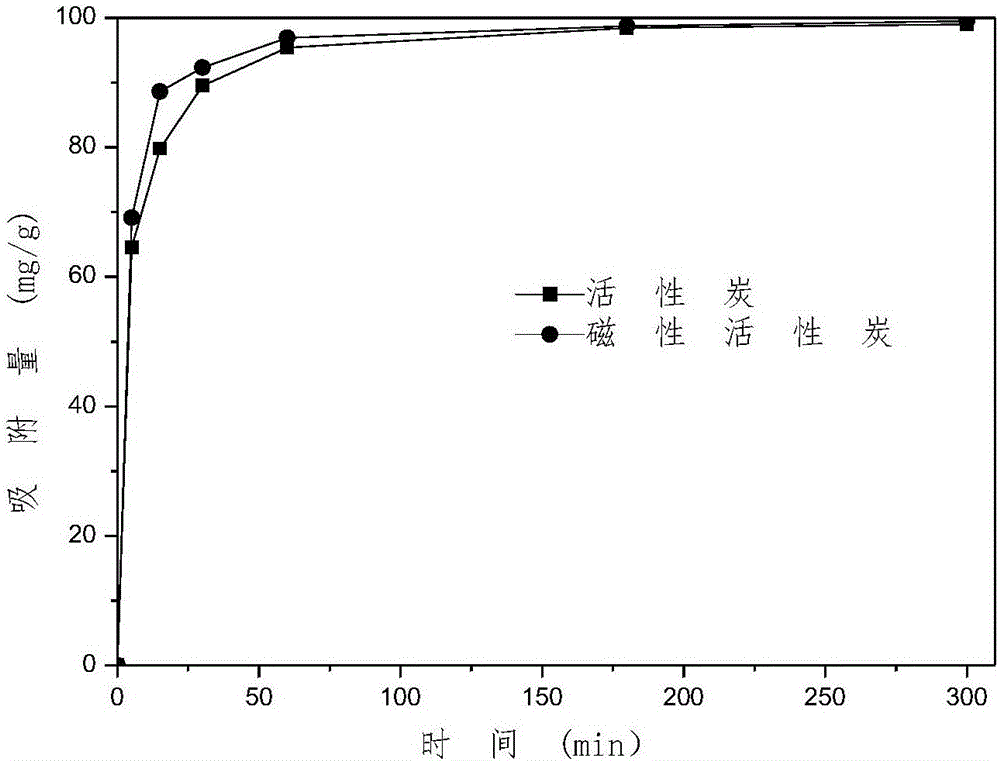

Embodiment 2

[0034] (1) Preparation of peanut shell activated carbon-based magnetic Cr(VI) adsorbent

[0035] Wash 5g of peanut shells with deionized water, dry in an oven at 100°C for 12h, and grind to 20-40 mesh. 2 Under the atmosphere, the heating rate was 5°C / min to 400°C, and the charred product was obtained after roasting at this temperature for 4 hours; then the carbonized product was dispersed in 28ml deionized water, and 6.2152g KOH was added, and after static immersion at room temperature for 6h Dry at 120°C for 12 hours, grind and then dry in N 2 After 5°C / min in the atmosphere, roast at 750°C for 30min, then wash the roasted activated product and dry it in vacuum at 60°C to obtain a peanut shell activated carbon sample.

[0036] Dissolve 0.1622g of ferric chloride hexahydrate in 60ml of ethylene glycol, add 0.4307g of anhydrous sodium acetate and stir for 30min, add 0.24g of peanut shell activated carbon sample, continue stirring at room temperature for 30min, then heat in water...

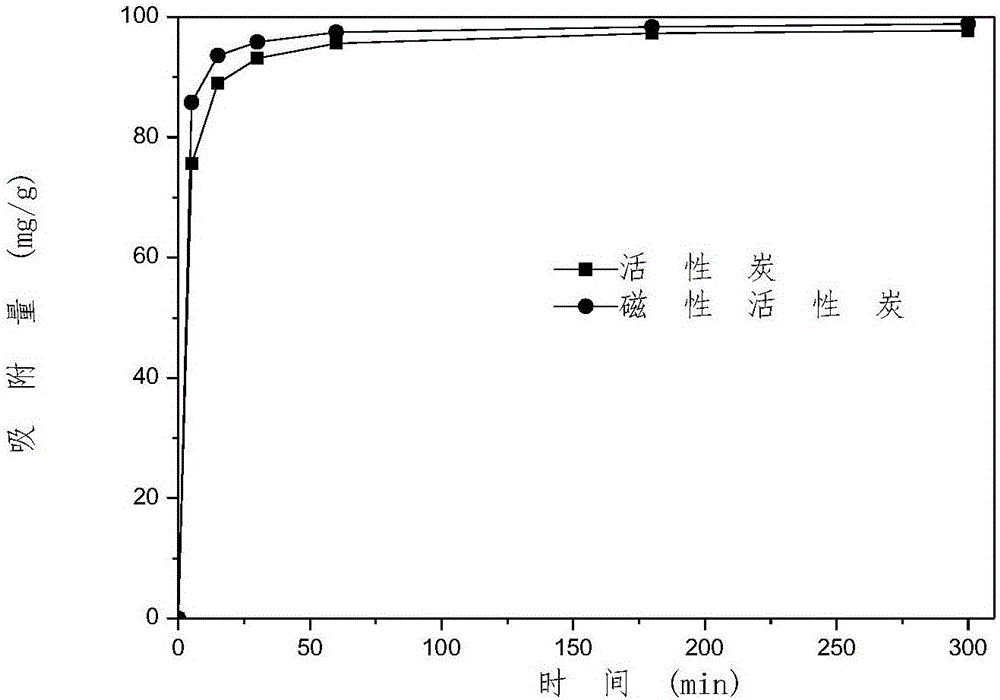

Embodiment 3

[0040] (1) Preparation of peanut shell activated carbon-based magnetic Cr(VI) adsorbent

[0041] Wash 5g of peanut shells with deionized water, dry in an oven at 100°C for 12h, and grind to 20-40 mesh. 2 Under the atmosphere, the heating rate was 5°C / min to 400°C, and the charred product was obtained after roasting at this temperature for 4 hours; then the carbonized product was dispersed in 28ml deionized water, and 6.2152g KOH was added, and after static immersion at room temperature for 8h Dry at 120°C for 12 hours, grind and then dry in N 2 Under the atmosphere, after 5°C / min, roast at 850°C for 30min, then wash the roasted activated product and dry it in vacuum at 60°C to obtain the peanut shell activated carbon sample.

[0042] Dissolve 0.1622g of ferric chloride hexahydrate in 60ml of ethylene glycol, add 0.4307g of anhydrous sodium acetate and stir for 30min, then add 0.24g of peanut shell activated carbon sample, continue stirring at room temperature for 30min, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetic strength | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Remanence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com