Nickel cobalt oxide<@>manganese dioxide nuclear shell heterostructure nanowire array grown on carbon cloth and preparation method and application thereof

A nanowire array and heterostructure technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve problems such as low energy density and power density, small active area of nanomaterials, and difficulty in meeting application requirements. , to achieve high energy density and power density, good reproducibility, and good crystal shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

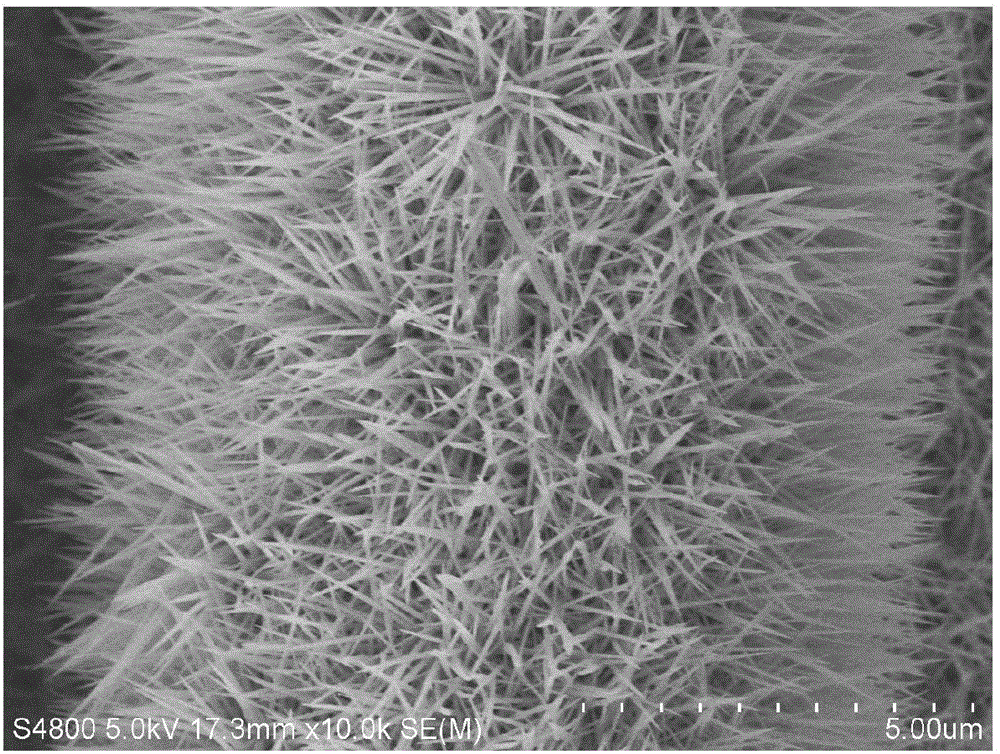

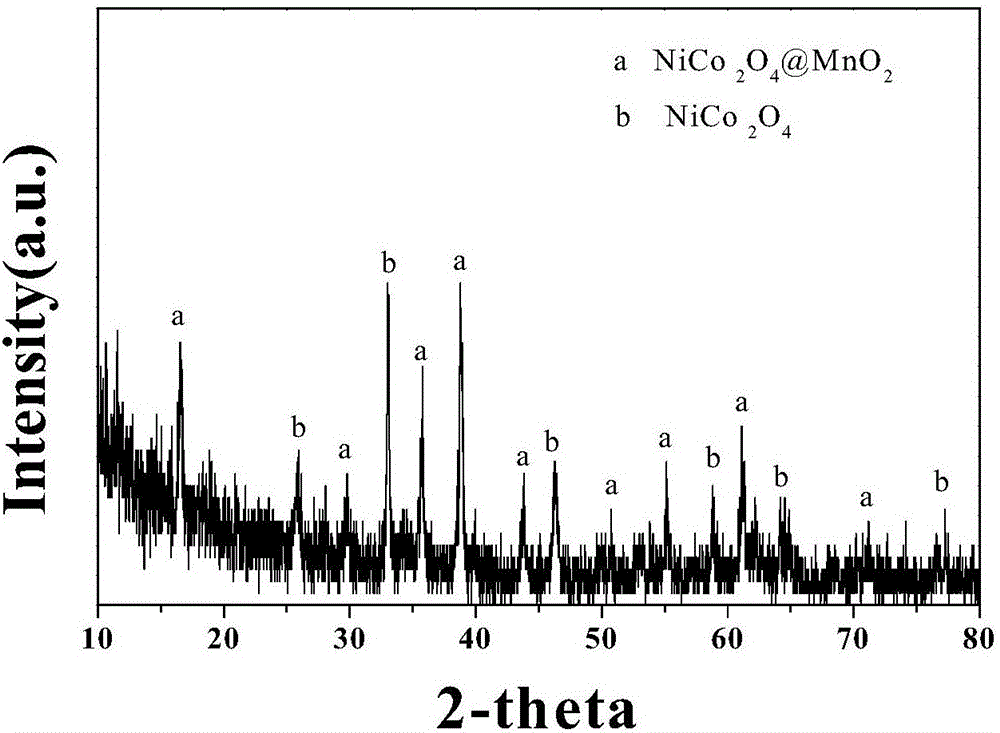

[0036] A method for preparing nickel cobaltate@manganese dioxide core-shell heterostructure nanowire arrays grown on carbon cloth, comprising the following steps:

[0037] a. Put the carbon cloth with impurities on the surface into dilute sulfuric acid, double distilled water, and ethanol in sequence for ultrasonic cleaning for 15 minutes;

[0038] b. Mix 40mL double-distilled water, 2mmol nickel chloride hexahydrate, 4mmol cobalt chloride hexahydrate, 15mmol cetyltrimethylammonium bromide and 9mmol urea, and then add them to a 60mL reactor, and place the treated carbon Immerse the cloth in the mixed solution, pour it into the reaction kettle, tighten the lid of the kettle, react at 110°C for 7 hours, take out the reaction kettle and cool it to room temperature naturally, wash with ethanol and double distilled water for 3-5 times respectively, rinse clean, and place in Drying at 60°C for 2h, and then calcining at 350°C for 3h in an air atmosphere, the nickel cobalt oxide nanow...

Embodiment 2

[0047] A method for preparing nickel cobaltate@manganese dioxide core-shell heterostructure nanowire arrays grown on carbon cloth, comprising the following steps:

[0048] a. Put the carbon cloth with impurities on the surface into dilute sulfuric acid, double distilled water, and ethanol in sequence for ultrasonic cleaning for 15 minutes;

[0049] b. Mix 40mL double-distilled water, 1mmol nickel chloride hexahydrate, 2mmol cobalt chloride hexahydrate, 9mmol urea, 15mmol cetyltrimethylammonium bromide and add them into a 60mL reaction kettle. Immerse in the mixed solution, pour it into the reaction kettle, tighten the lid of the kettle, react at 120°C for 6h, take out the reaction kettle and cool to room temperature naturally, rinse with ethanol and double distilled water in turn, dry at 60°C for 2h, and dry at 400°C Calcined for 3 hours under air atmosphere, the nickel cobalt oxide nanowire material was obtained.

[0050] c. Dissolve 0.079g of potassium permanganate in 40mL ...

Embodiment 3

[0055] A method for preparing nickel cobaltate@manganese dioxide core-shell heterostructure nanowire arrays grown on carbon cloth, comprising the following steps:

[0056] a. Put the carbon cloth with impurities on the surface into hydrochloric acid, ethanol, and double distilled water in sequence for ultrasonic cleaning for 20 minutes;

[0057] b. Mix 40mL double-distilled water, 1mmol nickel nitrate hexahydrate, 2mmol cobalt nitrate hexahydrate, 9mmol urea, 15mmol hexadecyltrimethylammonium bromide and add it into a 60mL reaction kettle. solution, pour it into the reaction kettle, tighten the lid of the kettle, react at 120°C for 6 hours, take out the reaction kettle and cool it to room temperature naturally, rinse it with ethanol and double-distilled water in turn, dry it at 60°C for 2 hours, and put it in an air atmosphere at 400°C Calcining at lower temperature for 3 hours, the nickel cobaltate nanowire material is obtained.

[0058] c. Dissolve 0.079g of potassium perma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com