A Supercooling Temperature Monitoring Method Based on Shape Memory Alloy

A memory alloy and supercooling technology, applied in the field of temperature monitoring and supercooling temperature monitoring based on shape memory alloy, can solve the problems of large volume and high cost, and achieve the effects of good reliability, simple use and wide use range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for monitoring supercooling temperature based on shape memory alloy, which is characterized in that it comprises the following steps:

[0028] Step 1. Take 15 mg disc-shaped nickel manganese gallium as the supercooling temperature monitoring material;

[0029] Step 2. After directly pasting the nickel manganese gallium to the fitting position on the surface of the monitored product, start the monitoring of the supercooling temperature;

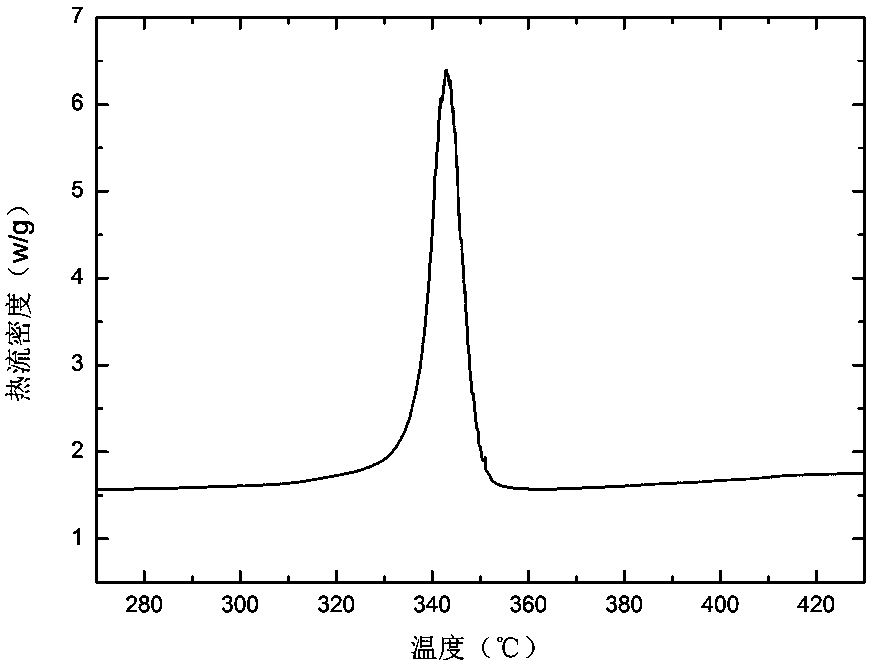

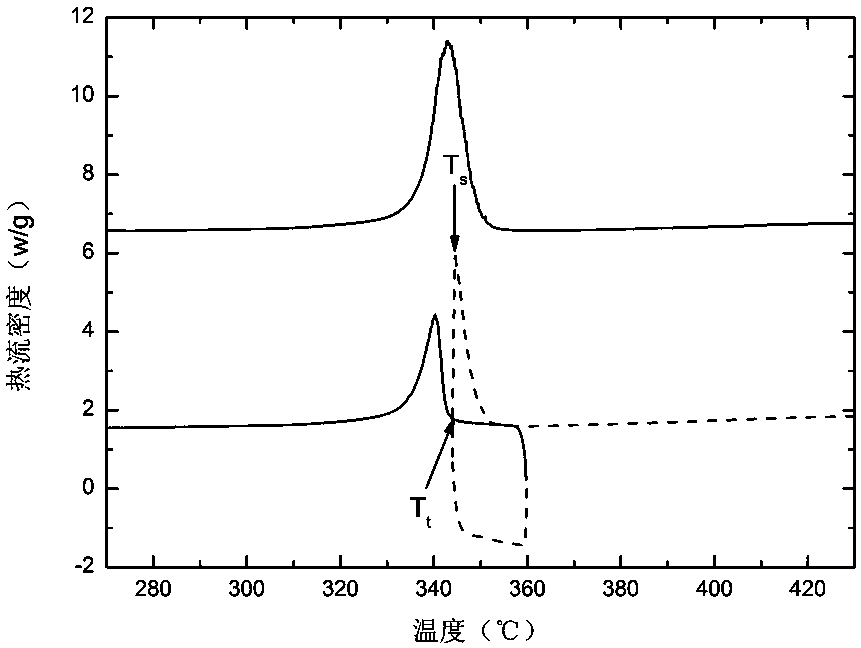

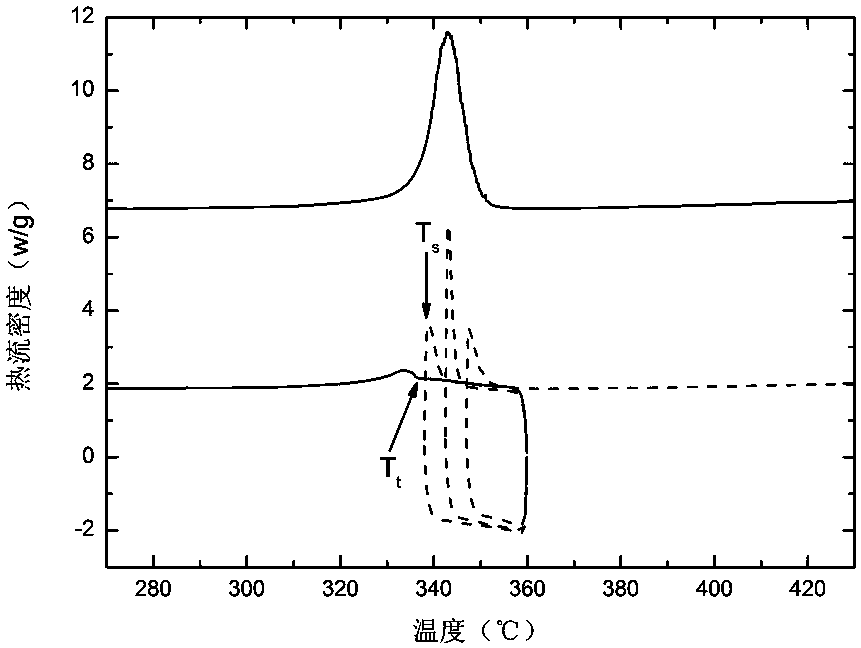

[0030] Step 3. After the monitoring is over, use thermal analysis equipment to analyze the supercooled temperature monitoring material, and compare the monitoring results with the original measurement results to determine whether the monitored product exceeds the minimum temperature and temperature during the monitoring process. Specific temperature information;

[0031] Step 4. Heat the said supercooling temperature monitoring material to a temperature above the austenite transformation completion temperature, so as to realize the reu...

Embodiment 2

[0034] Step 1. Take filiform titanium nickel with a weight of 10 mg as the supercooling temperature monitoring material;

[0035] Step 2. Paste the titanium nickel directly to the inner fitting position of the package box of the monitored product and then start the monitoring of the supercooling temperature; the others are the same as in Embodiment 1, and will not be repeated.

Embodiment 3

[0037] A method for monitoring supercooling temperature based on shape memory alloy, including the following steps:

[0038] Step 1. Take granular titanium nickel copper with a weight of 20 mg as the supercooling temperature monitoring material;

[0039] Step 2. Paste the titanium nickel copper directly to the outer fitting position of the package box of the monitored product, and then start the monitoring of the supercooling temperature; the others are the same as in Embodiment 1, and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com