Ice source heat pump system

A heat pump system, ice source technology, applied in lighting and heating equipment, heating and cooling combination, compressor with reversible cycle, etc., can solve the problems of low cooling and heating efficiency, poor heat dissipation, and easy frosting of the evaporator , to achieve the effect of high cooling and heating efficiency, excellent system structure and well-configured components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

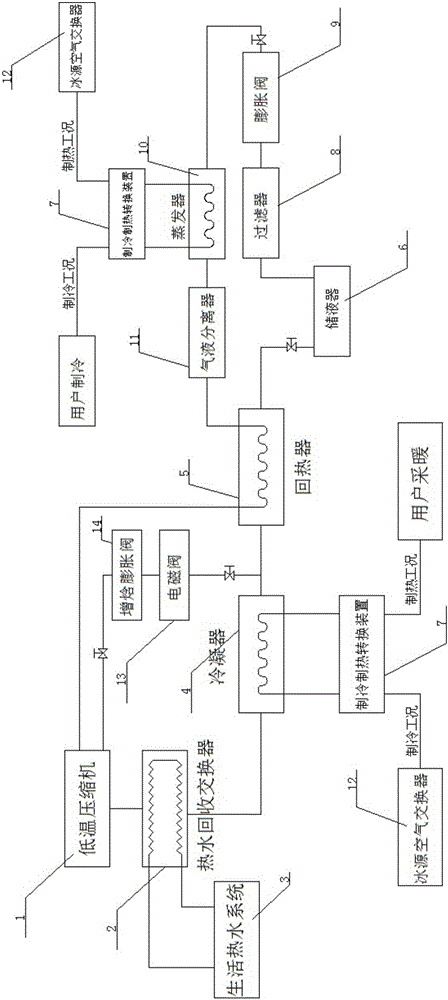

[0022] Such as figure 1 As shown, the system includes a compressor 1, a condenser 4, a liquid receiver 6, a filter 8, a throttling device 9, an evaporator 10, and a gas-liquid separator 11. The throttling device of this embodiment adopts an expansion valve 9, and the compression The function of machine 1 is to turn the refrigerant into high-temperature and high-pressure refrigerant vapor, and deliver the high-temperature and high-pressure gas to the condenser 4, and after being condensed by the condenser 4, it passes through the liquid receiver 6, the filter 8 and the expansion valve 9 to enter the evaporator 10. After being evaporated by the evaporator 10, it is returned to the compressor 1 by the gas-liquid separator 11. The refrigerant liquid condensed by the condenser 4 is stored in the accumulator 6, and the refrigerant in the accumulator 6 enters the evaporator 10 after being filtered and throttled, and the evaporator absorbs the heat of the air in the room to achieve co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com