Assembly type light heat insulation wall for building outer wall

A technology for building exterior walls and thermal insulation walls, applied in thermal insulation, construction, building components, etc. It can solve the problems of energy-saving and thermal insulation that are difficult to reach high standards, long time for on-site connection and installation, and a large number of assembly components, so as to avoid splicing seams Cracking, reduced connection installation time, reduced splicing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

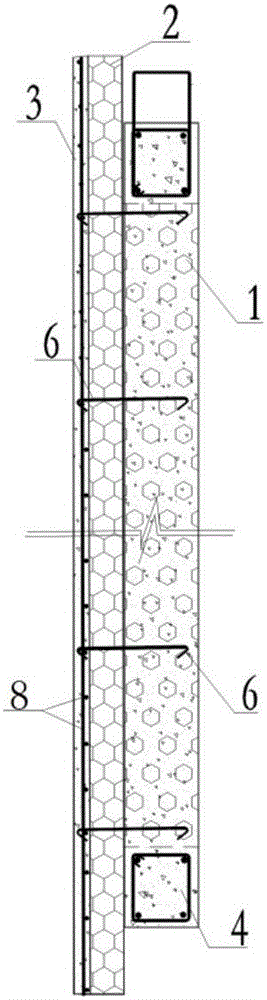

[0042] like Figure 1-3 As shown, the present embodiment is a lightweight thermal insulation wall for the exterior wall of a prefabricated building, which includes from the inside to the outside (i.e. figure 1 The prefabricated exterior wall panel composed of wall layer 1, polystyrene board (insulation layer 2), waterproof mortar plus fiber mesh layer (protection layer 3) and fixed connector 6 is arranged in sequence from front to back as shown, and its wall layer 1 The main part is made of lightweight aerated concrete walls, and reinforced concrete edge members 4 are arranged on the four sides of the wall layer, wherein the reinforced concrete edge members 4 on the left and upper parts of the wall panels are part of the main structure, and the right side is the edge of the building door opening The structural column, the lower part is the edge member 4 set for the integrity of the wall panel; the wall layer 1 is equipped with tensile material, which is the main steel bar of t...

Embodiment 2

[0051] like Figure 4-6 Shown, the thermal insulation wallboard of this embodiment, it comprises from inside to outside (ie Figure 4 As shown (from front to back), the prefabricated wallboard composed of wall layer 1, polystyrene board as insulation layer 2, reinforced concrete as protective layer 3 and fixed connector 6 is formed in sequence, and the main part of wall layer 1 is air-entrained Concrete lightweight wall, with reinforced concrete edge members 4 on the top of the board and steel member edge members 9 on the left and right sides, all of which are part of the main structure; the wall layer 1 is equipped with tensile materials including: reinforced concrete edges The main reinforcement of component 4, the edge component 9 of the steel component, and the lightweight wall are equipped with a single-layer geogrid 10 with low thermal conductivity. Grid 10, after the other end passes through insulation layer 2, is connected on the reinforcement mesh 7 in the protection...

Embodiment 3

[0061] like Figure 7-10 As shown, the present embodiment is a lightweight thermal insulation wall for the exterior wall of a prefabricated building, which includes from the inside to the outside (i.e. Figure 7 As shown from front to back) the prefabricated wallboard composed of wall layer 1, pasting mortar layer, extruded plastic board as insulation layer 2, reinforced concrete as protective layer 3 and fixed connector 6, whose wall layer is mainly Part is made of polyphenylene particle concrete lightweight wall, and the reinforced concrete edge members 4 on the left and right sides and the upper side are all part of the main structure; the wall layer 1 is equipped with tensile materials including: main steel bars of reinforced concrete members, The quality wall is equipped with double-layer bidirectional bamboo chips 5 (bamboo fiber) with low thermal conductivity, and one end of the fixed connector 6 is buried in the light wall of the wall layer 1 to hook the bamboo chips 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com