Nodular cast iron edging roll suitable for universal rolling mill and manufacturing method thereof

A ductile iron, universal rolling mill technology, applied in the field of rolls and manufacturing, ductile iron edge rolls and their manufacturing fields, can solve the problems of high production cost and long production cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

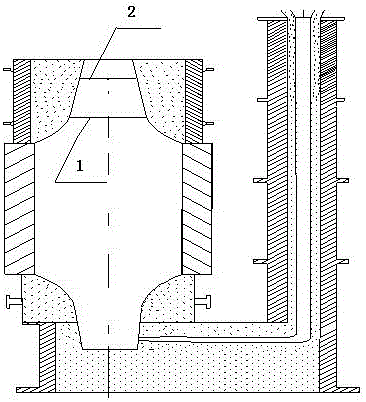

Image

Examples

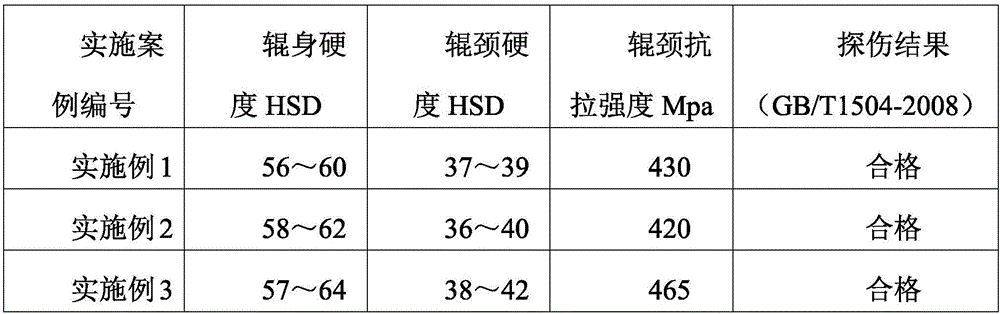

Embodiment 1

[0049] A nodular cast iron roll suitable for a universal rolling mill and a manufacturing method thereof, comprising a roll body, an upper roll neck and a lower roll neck, characterized in that: the chemical composition of the roll body and the lower roll neck is consistent, wherein the chemical composition of the roll body Points and weight percentages are:

[0050] C 3.15~3.3%, Si 0.8~1.2%, Mn 0.5~0.6%, Cr 0.5~0.6%, Ni 1.6~2.0%, Mo 0.2~0.45%, Re 0.05~0.08%, Mg≥0.04%, P≤0.04 , S≤0.04, the rest are Fe and unavoidable impurities;

[0051] In step b), the smelting temperature of the molten iron on the roll body is 1450°C, the addition of the inoculant is 0.45%, the addition of the nodulizer is 0.7% of the total amount of the molten iron, and the addition of the modifier is 0.25% of the total amount of the molten iron;

[0052] The smelting temperature of the molten iron on the upper roll neck is 1460°C, the addition amount of the inoculant is 0.45%, and the addition amount of t...

Embodiment 2

[0057] The present embodiment is the same as the process step in embodiment 1, and the difference with embodiment 1 is: in the present embodiment, the chemical composition and weight percentage of the roll body used for the ductile iron roll of the universal rolling mill are:

[0058] C 3.3~3.45%, Si 1.0~1.6%, Mn 0.5~0.65%, Cr 0.7~0.8%, Ni 1.8~2.2%, Mo 0.45~0.55%, Re 0.05~0.08%, Mg≥0.04%, P≤0.04 , S≤0.04, the rest are Fe and unavoidable impurities;

[0059] In step b), the smelting temperature of the molten iron on the roll body is 1500°C, the addition of the inoculant is 0.6%, the addition of the nodulizer is 0.8% of the total amount of the molten iron, and the addition of the modifier is 0.3% of the total amount of the molten iron;

[0060] The smelting temperature of the molten iron on the upper roll neck is 1490°C, the addition amount of the inoculant is 0.7%, and the addition amount of the nodulizer is 1.45% of the total amount of the molten iron.

[0061] According to t...

Embodiment 3

[0065] The present embodiment is the same as the process step in embodiment 1, and the difference with embodiment 1 is: the roll body chemical composition and the weight percentage composition of the nodular cast iron roll that is used for universal rolling mill in the present embodiment are:

[0066] C 3.45~3.6%, Si 1.6~2.0%, Mn 0.6~0.7%, Cr 0.8~1.0%, Ni 2.4~3.0%, Mo 0.6~0.7%, Re 0.08~0.1%, Mg≥0.04%, P≤0.04 , S≤0.04, the rest are Fe and unavoidable impurities;

[0067] In step b), the smelting temperature of the molten iron on the roll body is 1540°C, the addition of the inoculant is 0.9%, the addition of the nodulizer is 1.0% of the total amount of the molten iron, and the addition of the modifier is 0.4% of the total amount of the molten iron;

[0068] The smelting temperature of the molten iron on the upper roll neck is 1550°C, the addition amount of the inoculant is 0.8%, and the addition amount of the nodulizer is 1.6% of the total amount of the molten iron.

[0069] Ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com