Preparation method of resin matrix composite material toughened by nano-scale aluminum oxide hydroxide sheet material

A technology of aluminum oxyhydroxide and sheet material, which is applied in the field of preparation, can solve the problems of increased resin viscosity, difficulty in molding and processing composite materials, and failure to meet the load-bearing structure, and achieve the effect of improving interlayer fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

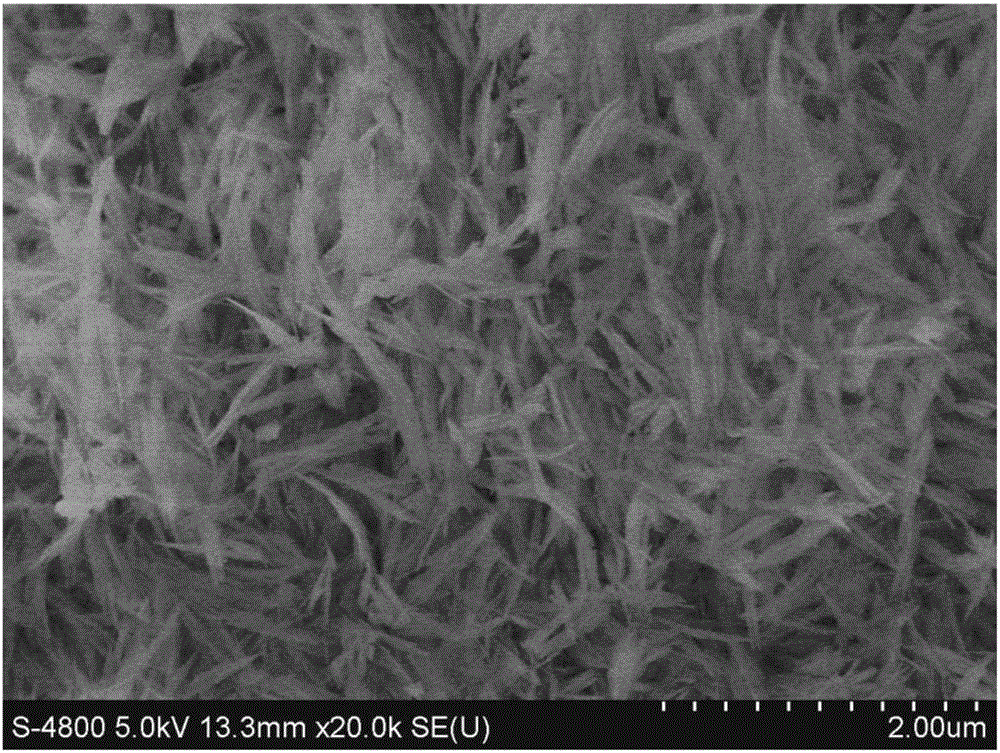

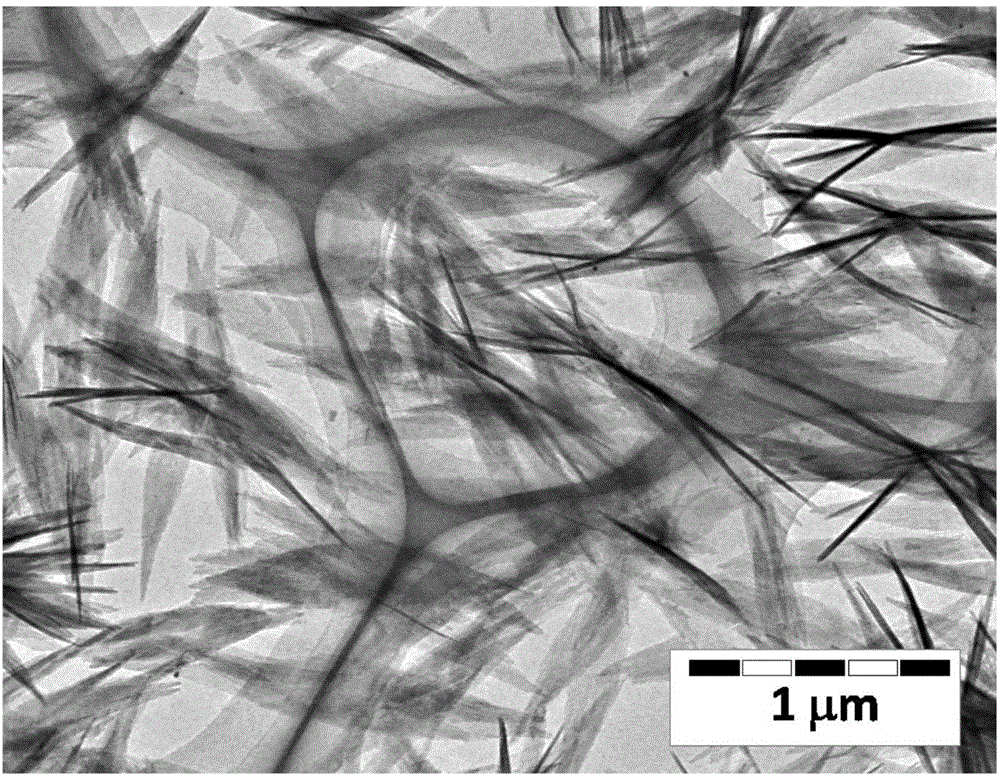

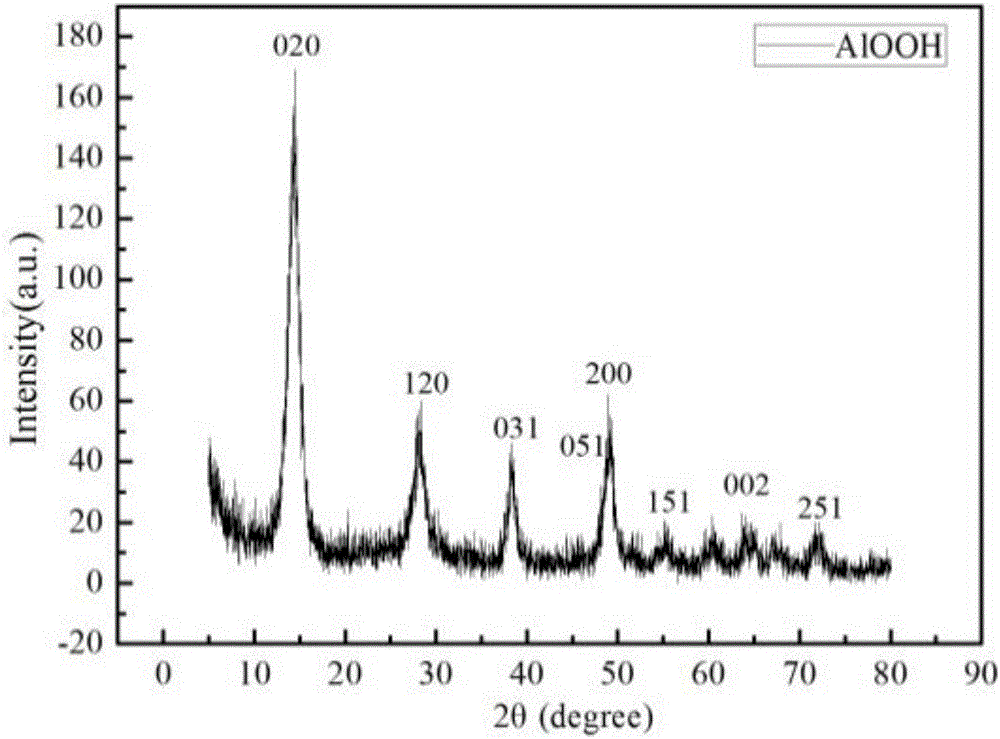

Image

Examples

Embodiment 1

[0023] Weigh 30g of aluminum nitrate, 9.1g of carbonamide, and 60ml of deionized water, mix them in a Erlenmeyer flask, place them in an oil bath at 50°C, and stir with a magnetic stirrer for 1 hour, then put the mixed solvent into the reaction kettle, together with the reaction kettle Put them together in an oven, raise the temperature to 160°C at a rate of 1°C / min, and keep it warm for 24 hours, then cool to room temperature naturally, pour the paste liquid in the reaction kettle into a beaker, and carry out ultrasonic stirring in deionized water , spread the filter paper into the suction filter funnel, then pour the liquid into the suction filter funnel for vacuum filtration several times, turn off the vacuum pump, soak and dry the reactant in the funnel with deionized water for 20 minutes, and repeat the suction filter, so Repeat several times until the filtrate dripping out of the funnel is not alkaline, and then filter it with ethanol several times in the funnel until the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com