Preparing method and application of ecological matrix particles for river water body enhanced nitrogen removal

A matrix particle and ecological technology, applied in the field of preparation of ecological matrix particles, can solve the problems of insufficient carbon source and low TN removal rate, and achieve the effects of low cost, abundant raw materials, and easy production and preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

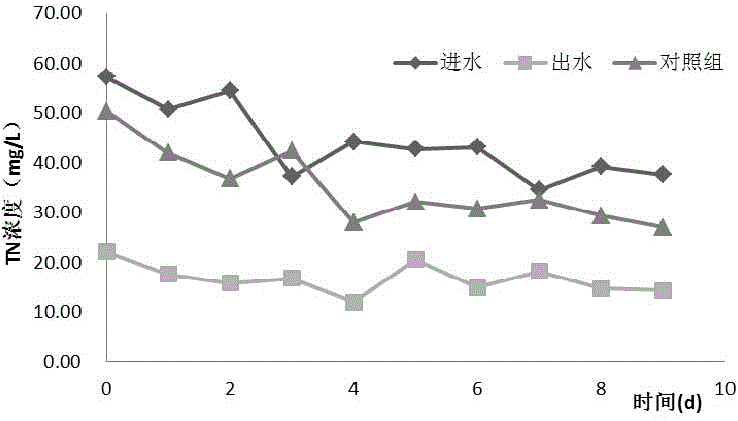

Image

Examples

Embodiment 1

[0020] The present invention in concrete implementation, comprises the following steps:

[0021] (1) Ingredients:

[0022] The ecological matrix particles are made of the following raw materials by weight: 5% corn cob, 20% diatomite, 20% calcium-based bentonite, 35% zeolite powder and 20% slag portland cement;

[0023] (2) Modification of corncobs: crush corncobs into particles passing through a 40-60 mesh sieve, add sodium hydroxide solution with a mass concentration of 2%, rinse with water after soaking for 2 hours until the pH is neutral, and place in an oven at 60°C Dry and irradiate with ultraviolet light for 10 hours to obtain modified corncobs (granules);

[0024] (3) Granulation: Mix diatomite, calcium-based bentonite, zeolite powder, slag Portland cement and modified corncobs evenly with a mixer, and put them into a round pot granulator to granulate at 20-25r / min Under the rotating speed, use the sprayer to continuously spray water mist into the granulator, so that ...

Embodiment 2

[0031] The present invention in concrete implementation, comprises the following steps:

[0032] (1) Ingredients:

[0033] The ecological matrix particles are made of the following raw materials by weight: 4% corn cob, 19% diatomite, 19% calcium-based bentonite, 33% zeolite powder, 12% ordinary Portland cement and 13% fly ash;

[0034] (2) Modification of corncobs: crush corncobs into particles passing through a 40-60 mesh sieve, add sodium hydroxide solution with a mass concentration of 2%, soak for 2 hours, rinse with water until the pH is neutral, and place in an oven at 60°C Dry and irradiate with ultraviolet light for 10 hours to obtain modified corncobs (granules);

[0035] (3) Granulation: Stir and mix diatomite, calcium-based bentonite, zeolite powder, ordinary Portland cement, fly ash and modified corncobs evenly, put them into a round pot granulator for granulation, and granulate at 20-25r At the rotation speed of / min, use a sprayer to continuously spray water mis...

Embodiment 3

[0039] The batching can also be made from the following raw materials by weight: 3% corn cob, 30% diatomite, 35% zeolite powder, 11% slag portland cement and 11% fly ash. The preparation method is the same as in the examples 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com