Method for preparing nanometer ZnO cellulose composite based on NaOH/urea solution by using direct precipitation process, and application of nanometer ZnO cellulose composite

A composite material and cellulose technology, applied in the field of nano-ZnO cellulose composite materials, can solve the problems of difficult wide application and high cost of ionic liquids, and achieve the effect of simple method, simple and easy equipment, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 50g of NaOH / Urea aqueous solution (NaOH:Urea:H 2 The mass ratio of O is 7︰12︰81), add 2g microcrystalline cellulose, stir rapidly until dissolved, add 1mol / L ZnCl dropwise 2 Solution 30mL, after stirring and aging for 30min, with 2% H 2 SO 4 Adjust the pH value of the solution to 9, reflux at 90°C for 2 hours, take it out and wash it with distilled water until there is no Cl - , dried in an oven at 70°C and weighed to obtain a nano-ZnO cellulose composite material.

[0024] The prepared nano-ZnO cellulose composites were characterized as follows:

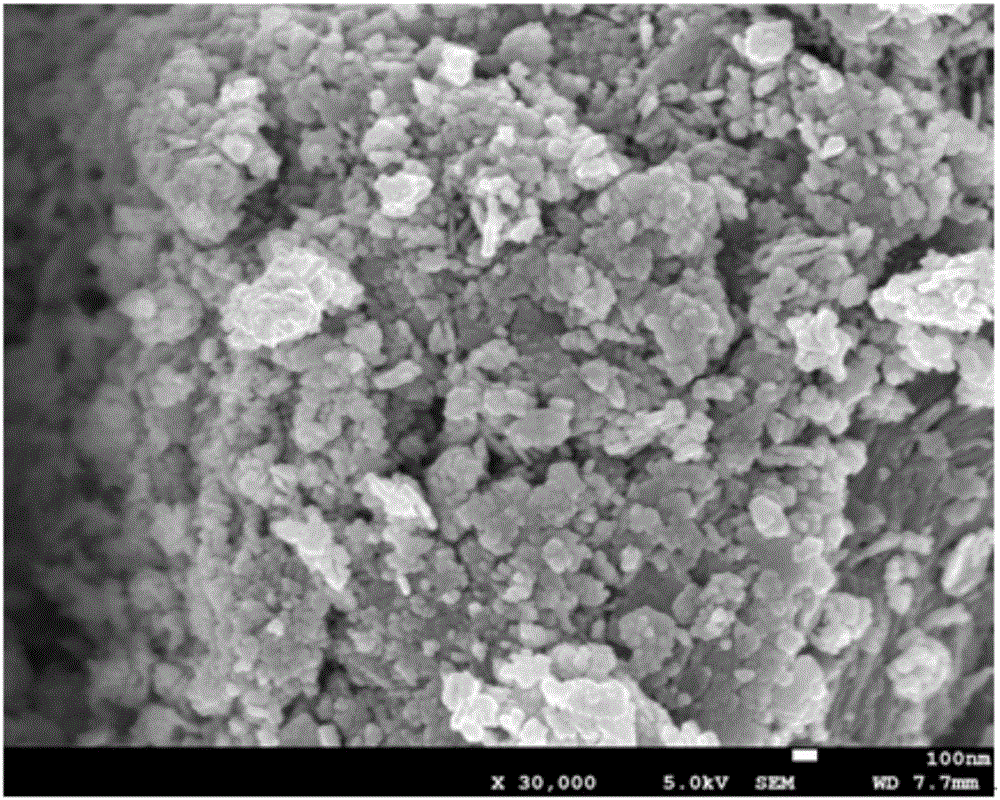

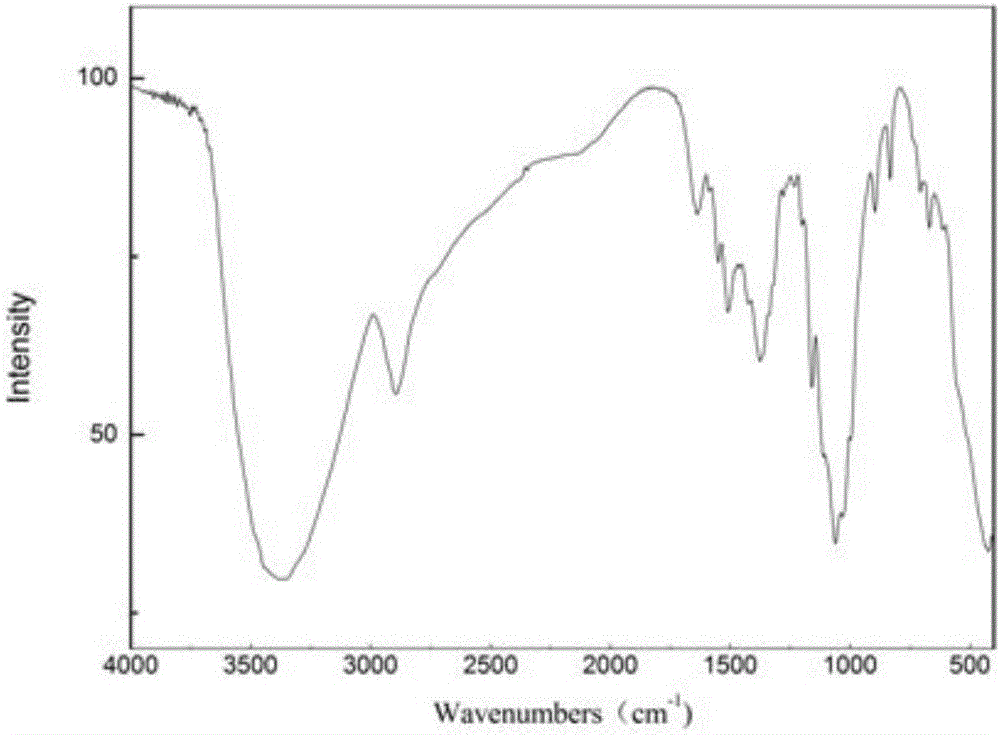

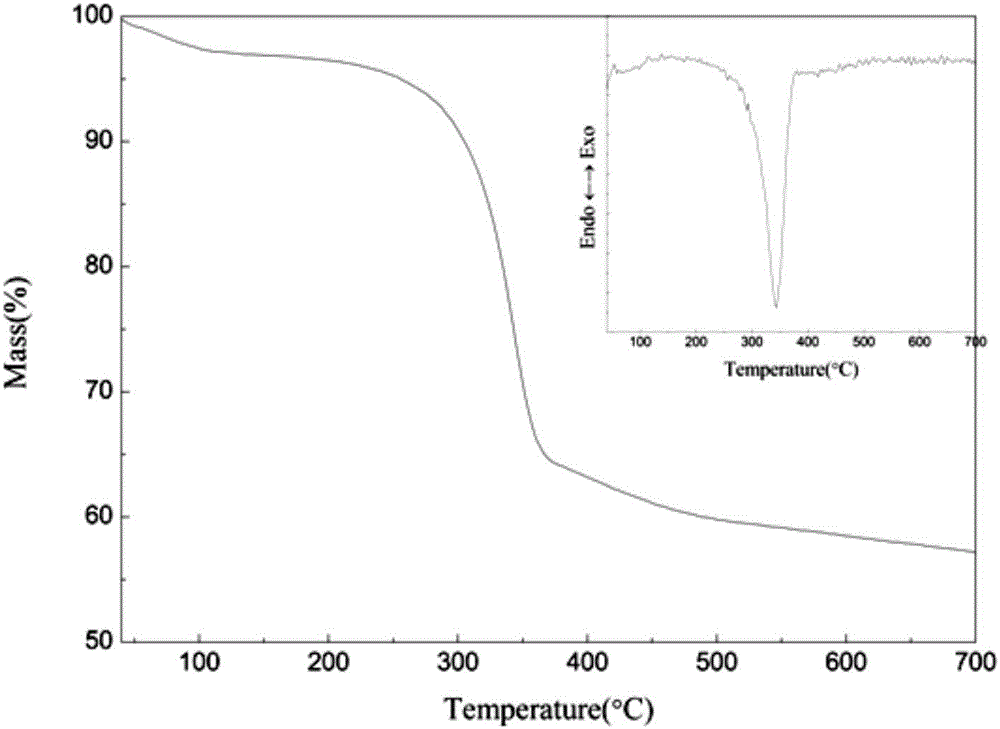

[0025] Electron micrographs of the prepared nano-ZnO cellulose composites are as follows: figure 1 As shown, the infrared image is shown as figure 2 As shown, TG as image 3 As shown, the XRD pattern is as Figure 4 . It can be seen from the electron microscope that ZnO gathers on the surface of cellulose in the form of nanosheets, and the infrared image is 472cm -1 The wave number is the characteristic peak of...

Embodiment 2

[0026] Photodegradation performance of embodiment 2 ZnO cellulose nanocomposites to methylene blue wastewater

[0027] Get the methylene blue solution (30mg / L, 40mg / L, 50mg / L, 60mg / L) of 100mL different initial concentrations in the 250mL quartz beaker, add ZnO / cellulose composite material 0.1g obtained in the embodiment 1, Stir on a magnetic stirrer, after stirring in the dark for 30min, under the irradiation of ultraviolet light and sunlight, take samples and analyze the concentration of methylene blue in the solution at regular intervals, stir for 4 hours altogether, and the removal rates of methylene blue after 4 hours are respectively 69.73%, 65.78%, 62.96%, 60.07%. (Concentration of methylene blue in the control sample ZnO and cellulose is 50mg / L, other conditions are unchanged)

[0028] The concentration of methylene blue was obtained by measuring the absorbance at 664 nm with a UV-visible spectrophotometer according to the methylene blue standard curve.

[0029] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com