Catalyst for preparation of isobutylene from isobutane through fixed bed dehydrogenation and preparation method thereof

A catalyst and fixed bed technology, which is applied in the field of isobutene catalytic dehydrogenation of isobutane and its preparation field, can solve the problems of insufficient thermal stability, poor mechanical strength, poor activity, etc., achieve good industrial application prospects, improve Thermal stability, activity-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

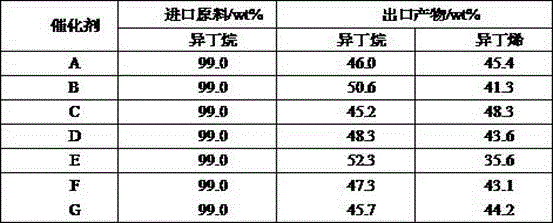

Examples

Embodiment 1

[0026] Weigh 50 grams of Cr(NO 3 ) 3 •9H 2 O, 283.8 g Al(NO 3 ) 3 9H 2 O, 0.876 g Ni(NO 3 ) 2 ·6H 2 O, 0.891 g TiCl 4 Dissolve in 2237mL deionized water, stir evenly; then slowly drop in 0.25mol / L Na 2 CO 3 Solution to pH value of 9, continue to stir for 5min, then sonicate for 5min, then stand and age for 2h, then filter, wash, add 6.52 grams of aluminum sol (containing 23wt%Al 2 o 3 ) extrusion molding, drying, and finally put the above catalyst in a tubular muffle furnace, pass in a mixed atmosphere of water vapor and air (volume ratio 1:4), control the calcination temperature at 850 °C, and the volume space velocity of the mixed atmosphere is 500h -1 , Calcined for 4h to obtain catalyst A.

Embodiment 2

[0028] Weigh 26.5 grams of Cr 2 (SO 4 ) 3 , 289.3 grams of Al(NO 3 ) 3 9H 2 O, 0.876 g Ni(NO 3 ) 2 ·6H 2 O, 0.891 g TiCl 4 Dissolve in 907mL deionized water, stir evenly; then slowly drop in 0.75mol / L Na 2 CO 3 Solution to pH value of 11, continue to stir for 5min, then sonicate for 5min, then stand and age for 2h, then filter, wash, add 3.26 grams of aluminum sol (containing 23wt%Al 2 o 3) extrusion molding, drying, and finally put the above catalyst in a tubular muffle furnace, pass in a mixed atmosphere of water vapor and air (volume ratio of 2:3), control the calcination temperature at 750 ° C, and the volume space velocity of the mixed atmosphere is 300h -1 , Calcined for 7h to obtain catalyst B.

Embodiment 3

[0030] Weigh 33.3 g CrCl 4 •6H 2 O, 287.4 g Al(NO 3 ) 3 9H 2 O, 0.876 g Ni(NO 3 ) 2 ·6H 2 O, 0.891 g TiCl 4 Dissolve in 1612mL deionized water, stir evenly; then slowly drop in 0.50mol / L Na 2 CO 3 Solution to pH value of 9.8, continue to stir for 5min, then sonicate for 5min, then stand and age for 2h, then filter and wash; add 4.35 grams of aluminum sol (containing 23wt%Al 2 o 3 ) extrusion molding, drying, and finally put the above catalyst in the tubular muffle furnace, pass into the mixed atmosphere of water vapor and air (volume ratio is 3:2), control the calcination temperature to 950 ℃, the volume space velocity of the mixed atmosphere is 200h -1 , Calcined for 5h to obtain catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com