Preparation method for supported zinc oxide photocatalyst

A photocatalyst, zinc oxide technology, applied in the field of photocatalytic materials, to achieve the effect of improving activity and efficiency, improving utilization rate, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

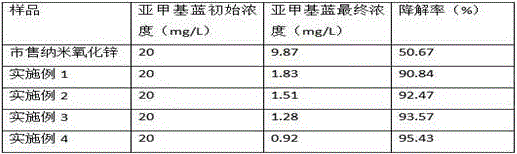

Examples

Embodiment 1

[0026] A preparation method of supported zinc oxide photocatalyst, comprising the following steps:

[0027] (1) Weigh each raw material according to the proportion: 30g of zinc nitrate hexahydrate, 5g of polyethylene glycol stearate, 15g of thiourea, 5g of red mud, 1g of cobalt carbonate and 10g of kaolin;

[0028] (2) Add zinc nitrate hexahydrate into the ultrasonic generator, add 200mL of absolute ethanol to dissolve, then add sodium hydroxide solution with a concentration of 3mol / L to adjust the pH to 13, and continue ultrasonication at a frequency of 40KHz for 30min to obtain a suspension Turbid liquid A;

[0029] (3) Add thiourea into the stirrer, then add 100mL of water and stir to dissolve it to obtain suspension B;

[0030] (4) Pour suspension B into an ultrasonic generator equipped with suspension A, then add polyethylene glycol stearate, and continue ultrasonication for 60 minutes at a frequency of 40KHz to obtain a mixed solution;

[0031] (5) Put the mixture, red...

Embodiment 2

[0034] A preparation method of supported zinc oxide photocatalyst, comprising the following steps:

[0035] (1) Weigh each raw material according to the proportion: 40g of zinc nitrate hexahydrate, 8g of polyethylene glycol stearate, 20g of thiourea, 8g of red mud, 1.5g of cobalt carbonate and 12g of kaolin;

[0036] (2) Add zinc nitrate hexahydrate into the ultrasonic generator, add 250mL of absolute ethanol to dissolve, then add sodium hydroxide solution with a concentration of 5mol / L to adjust the pH to 13, and continue ultrasonication at a frequency of 60KHz for 20min to obtain a suspension Turbid liquid A;

[0037] (3) Add thiourea into the stirrer, then add 120mL of water and stir to dissolve it to obtain suspension B;

[0038] (4) Pour suspension B into an ultrasonic generator equipped with suspension A, then add polyethylene glycol stearate, and continue ultrasonication for 45 minutes at a frequency of 50KHz to obtain a mixture;

[0039] (5) Put the mixture, red mud,...

Embodiment 3

[0042] A preparation method of supported zinc oxide photocatalyst, comprising the following steps:

[0043] (1) Weigh each raw material according to the proportion: 50g of zinc nitrate hexahydrate, 10g of polyethylene glycol stearate, 18g of thiourea, 8g of red mud, 2g of cobalt carbonate and 15g of kaolin;

[0044] (2) Add zinc nitrate hexahydrate into the ultrasonic generator, add 350mL of absolute ethanol to dissolve, then add sodium hydroxide solution with a concentration of 1mol / L to adjust the pH to 12, and continue ultrasonication at a frequency of 60KHz for 30min to obtain a suspension Turbid liquid A;

[0045] (3) Add thiourea into the stirrer, then add 120mL of water and stir to dissolve it to obtain suspension B;

[0046] (4) Pour suspension B into an ultrasonic generator equipped with suspension A, then add polyethylene glycol stearate, and continue ultrasonication for 30 minutes at a frequency of 60KHz to obtain a mixture;

[0047] (5) Put the mixture, red mud, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com