Micro quantum organic waste gas and odor integrated processing system

A treatment system and waste gas treatment technology, used in gas treatment, dispersed particle separation, air quality improvement, etc., can solve the problems of difficult control of the growth balance of various microorganisms, enhance the ability of dispersion and suspension, avoid damage, and prevent dirt from reappearing. effect of deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

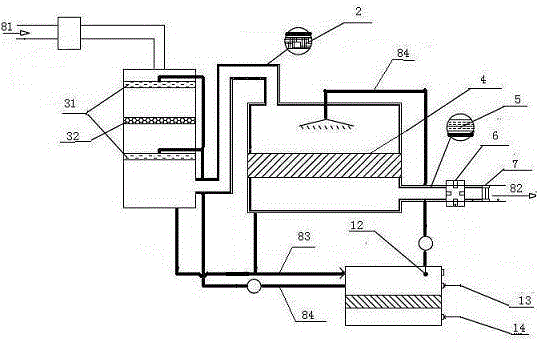

[0033] As shown in the accompanying drawing, a micro-quantum organic waste gas and odor integrated treatment system includes a body, a micro-quantum ecological ball circulating water treatment system, a class A micro-quantum nanomaterial inner coating (2), and a microbial group strain treatment system ( 4), Class B micro-quantum inner coating (5), photohydrogen ion treatment system (6), class C micro-quantum material honeycomb fence (7), system heat preservation and antifreeze system;

[0034] The body includes a chassis and pipelines, and the chassis includes a pretreatment box, an exhaust gas treatment box and a circulating water treatment box; the pipeline includes an air inlet pipe (81), an air outlet pipe (82), a return pipe (83), a return pipe (83), an air inlet pipe ( 81) Connect with the pretreatment box, the pretreatment box is then co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com