A treatment method and device for sulfur-containing organic waste gas

A technology for organic waste gas and treatment methods, applied in separation methods, combustion methods, chemical instruments and methods, etc., can solve problems such as poor economy, waste of hydrocarbon resources, failure to recover hydrocarbons, etc., and achieve enhanced stability and safety , to ensure the effect of organic matter concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

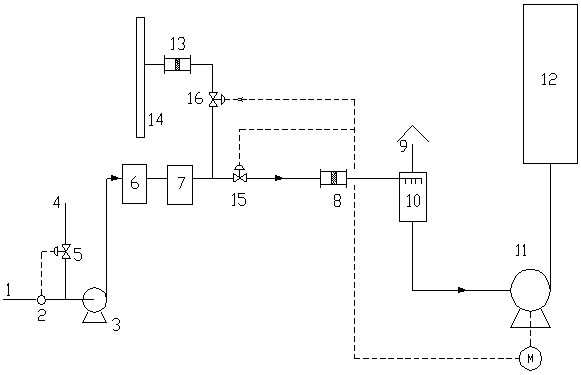

[0036] Adopt the present invention to attach figure 1 The process of treating the waste gas discharged from the acid water tank of a refinery, the waste gas discharge is 0-300m 3 / h, the total hydrocarbon concentration is 300-400g / m 3 , the organic sulfide content is 100-2000mg / m 3 , H 2 The S content is 10000-80000mg / m 3 . Use regular third-line gas oil to absorb, and the absorbed liquid-gas ratio is 100L / m 3 , the absorption temperature is 35°C, the absorption pressure is 100kPa, and the total hydrocarbon concentration of the exhaust gas after absorption is 25000-30000 mg / m 3 . When the storage tank has no breathing exhaust gas (exhaust gas emission is 0), introduce a certain amount of air to maintain the stability of the pressure of the diesel absorption equipment, and at the same time, the air will take out some organic matter through the diesel oil, so that the total hydrocarbon concentration is stabilized at 5000-20000mg / m 3 . After diesel oil is absorbed, 10% ...

Embodiment 2

[0038] Adopt the present invention to attach figure 1 The process of treating the waste gas discharged from the acid water tank of a refinery, the waste gas discharge is 0-500m 3 / h, the total hydrocarbon concentration is 200-400g / m 3 , the organic sulfide content is 500-2500mg / m 3 , H 2 S content is 5000-80000mg / m 3 . Use regular third-line gas oil to absorb, and the absorbed liquid-gas ratio is 100L / m 3 , the absorption temperature is 35°C, the absorption pressure is 150kPa, and the total hydrocarbon concentration in the waste gas after absorption is 22000-28000 mg / m 3 . When the storage tank has no breathing exhaust gas (exhaust gas emission is 0), introduce a certain amount of air to maintain the stability of the pressure of the diesel absorption equipment, and at the same time, the air will take out some organic matter through the diesel oil, so that the total hydrocarbon concentration is stabilized at 5000-20000mg / m 3 . After diesel oil is absorbed, 15% sodium ...

Embodiment 3

[0040] Adopt the present invention to attach figure 1 The process of treating the waste gas discharged from the oil tundish tank of a refinery, the waste gas discharge is 0-300m 3 / h, the total hydrocarbon concentration is 300-500g / m 3 , the organic sulfide content is 500-2000mg / m 3 , H 2 S content is 5000-80000mg / m 3 . Use regular third-line gas oil to absorb, and the absorbed liquid-gas ratio is 100L / m 3 , the absorption temperature is 8°C, the absorption pressure is 100kPa, and the total hydrocarbon concentration in the exhaust gas after absorption is 10000-18000 mg / m 3 . When the storage tank has no breathing exhaust gas (exhaust gas emission is 0), introduce a certain amount of air to maintain the stability of the pressure of the diesel absorption equipment, and at the same time, the air will take out some organic matter through the diesel oil, so that the total hydrocarbon concentration is stabilized at 5000-20000mg / m 3 . After diesel oil is absorbed, 10% sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com