Automotive antifreeze fluid and preparation method thereof

An automobile antifreeze and polyol technology, applied in the field of antifreeze, can solve the problems of non-compliance with environmental protection requirements, low thermal conductivity of scale, corrosion damage of metal parts, etc. Anti-freeze effect, excellent anti-corrosion protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

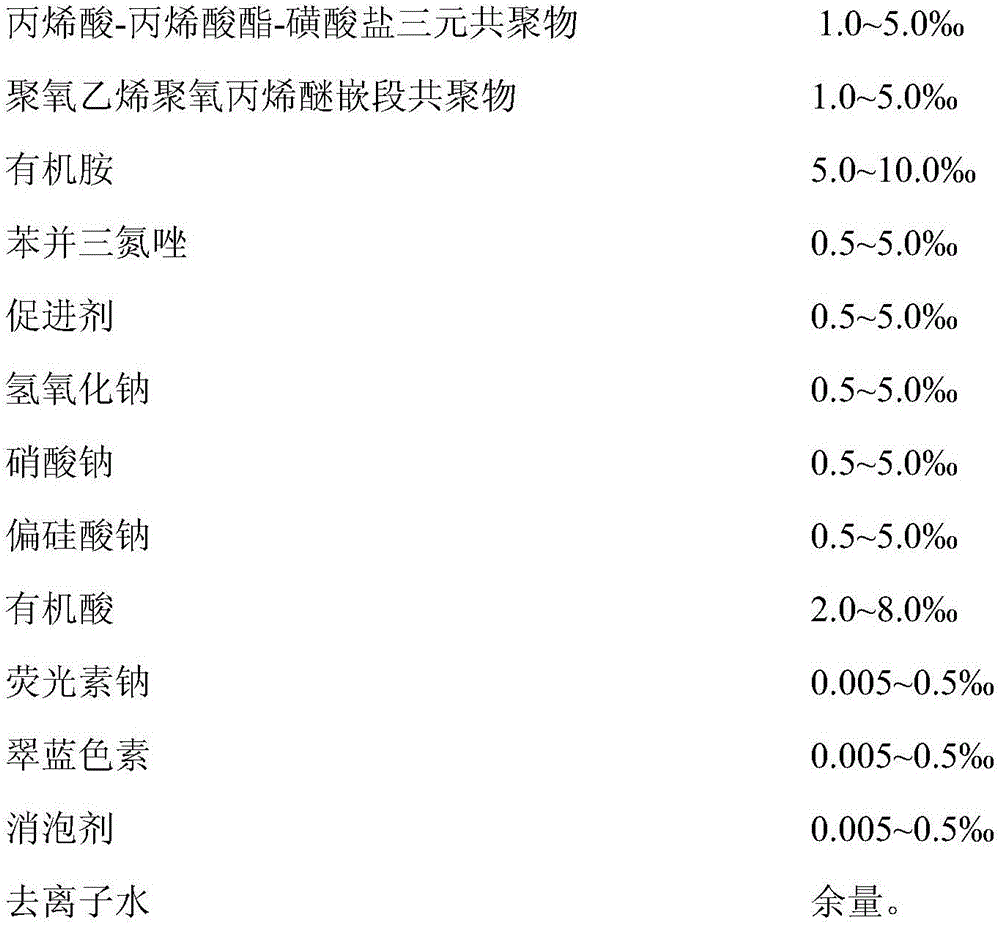

Embodiment 1

[0028] Put 550kg of ethylene glycol and 429kg of deionized water into a 2000L platform tank, start the agitator and stir for 10 minutes, after mixing evenly, add 1.5kg of acrylic acid-acrylate-sulfonate terpolymer TH-615 under stirring , 3.5kg of polyoxyethylene polyoxypropylene ether block copolymer Pluronic L61, fully stirred until the copolymer is uniformly dispersed, and then 8.4kg of triethylamine, 1kg of benzotriazole, 0.8kg of dibenzothiazole disulfide, 1.2kg sodium hydroxide, 1kg sodium nitrate, 1kg sodium metasilicate, 2.5kg adipic acid, 0.01kg fluorescein sodium, 0.05kg turquoise blue pigment and 0.04kg defoamer BYK-094, fully stir for 1 hour after feeding Packaging, get car antifreeze.

Embodiment 2

[0030] Put 454kg of propylene glycol and 525kg of deionized water into a 2000L platform tank, start the stirrer and stir for 15min, after mixing evenly, add 3kg of acrylic acid-acrylic acid ester-sulfonate terpolymer XT-613, 2kg of poly Oxyethylene polyoxypropylene ether block copolymer Antarox L64, stir well until the copolymer is evenly dispersed, then add 8kg triethanolamine, 1kg benzotriazole, 1kg2-mercaptobenzothiazole, 1.2kg sodium hydroxide, 1kg nitric acid Sodium, 1kg of sodium metasilicate, 2.7kg of sebacic acid, 0.02kg of sodium fluorescein, 0.05kg of turquoise blue and 0.03kg of antifoaming agent BYK-028 were fully stirred for 1.2 hours after feeding and packed to obtain automobile antifreeze.

Embodiment 3

[0032] Put 246kg of ethylene glycol, 254kg of propylene glycol, and 479kg of deionized water into a 2000L platform tank, start the agitator and stir for 20 minutes, after mixing evenly, add 3.8kg of acrylic acid-acrylic acid ester-sulfonate terpolymer under stirring XT-241, 1.2kg polyoxyethylene polyoxypropylene ether block copolymer Tergitol L62, fully stirred until the copolymer is uniformly dispersed, then put in 8kgN,N-dimethylethanolamine, 1kgbenzotriazole, 1kg2-( 2,4-dinitrophenylthio)benzothiazole, 1.2kg sodium hydroxide, 1kg sodium nitrate, 1kg sodium metasilicate, 2.66kg lauric acid, 0.01kg fluorescein sodium, 0.08kg turquoise blue and 0.05 kg defoamer Tego Foamex 810, fully stirred for 1.5 hours after feeding, and packed to obtain automobile antifreeze.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com