Process method for alcohol extraction of palmatine

A process method and alcohol extraction technology, applied in the field of plant extraction, can solve the problems of large sewage treatment volume, large amount of salt used for salting out, and long operation time, so as to improve the extraction rate, facilitate filtration, and reduce the number of times of cleaning the filter screen. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

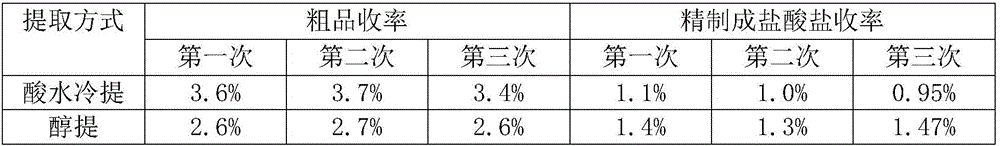

Examples

Embodiment 1

[0033] The present invention comprises the following steps:

[0034] 1) Extract 200 g of the vine root powder with alcohol for 4 times, the extraction temperature is controlled at 60° C. for 2 hours each time, and the combined filtrate is cooled and then filtered to remove insoluble impurities to obtain the filtrate. 15 (3000ml) times, the alcohol is methanol;

[0035] 2) the filtrate is evaporated to dryness to obtain a solid residue, and the solid residue is eluted with an acid solution to obtain an eluent. The volume of the acid solution is 2 times (300ml) of the solid residue quality, and the acid solution is sulfuric acid. The volume concentration of the liquid is 0.5%;

[0036] 3) After filtering the eluent, adjust the base, control the pH value at 9, leave it to stand until the insoluble matter is precipitated, then filter, carry out salting-out on the filtrate, filter to obtain the crude product after salting-out, use sodium hydroxide for base adjustment, the concentr...

Embodiment 2

[0039] The present invention comprises the following steps:

[0040] 1) Extract 200 g of yellow vine powder with alcohol for 3 times, the extraction temperature is controlled at 70° C. for 3 hours each time, the combined filtrate is cooled and filtered to remove insoluble impurities to obtain filtrate. The total volume of alcohol is 1 / 2 of the quality of yellow vine powder 18 times (3600ml), the alcohol is ethanol;

[0041] 2) The filtrate was evaporated to dryness to obtain a solid residue, and the solid residue was eluted with an acid solution to obtain an eluent, the amount of the acid solution was 350ml, the acid solution was hydrochloric acid, and the volume concentration of the acid solution was 0.6%;

[0042] 3) After filtering the eluent, adjust the base, the pH value is controlled at 9, and the base adjustment adopts potassium hydroxide, and the concentration is 40%; leave it to stand and filter after insoluble matter is separated out, and the filtrate is salted out, ...

Embodiment 3

[0045] The present invention comprises the following steps:

[0046] 1) Extract 200 g of yellow vine powder with alcohol for 3 times, the extraction temperature is controlled at 50° C., for 2 hours each time, the combined filtrate is cooled and filtered to remove insoluble impurities to obtain filtrate. The volume of alcohol is 15% of the quality of yellow vine powder. times (3000ml), the alcohol adopts isopropanol;

[0047] 2) The filtrate was evaporated to dryness to obtain a solid residue, and the solid residue was eluted with an acid solution to obtain an eluent, the amount of the acid solution was 500ml, the acid solution was acetic acid, and the volume concentration of the acid solution was 0.7%;

[0048] 3) After filtering the eluent, adjust the base, control the pH value at 10, leave it to stand until the insoluble matter is precipitated, and then filter, then salt the filtrate, the volume of the filtrate is about 550ml, add 50g of sodium chloride for salting out for 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com