Water treatment agent and preparation method thereof

A water treatment agent, sodium humate technology, applied in water/sludge/sewage treatment, chemical instruments and methods, descaling and water softening, etc., can solve problems such as equipment corrosion and cycle turning, black, etc., to achieve lightening Pollution, effect enhancement, effect of inhibiting bacteria and algae

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of a water treatment agent, comprising the steps:

[0023] S1, 10kg sodium humate is added to the reactor, then 50kg water is added in the reactor, heating and stirring makes the sodium humate dissolve completely;

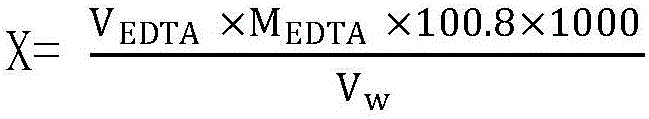

[0024] S2, keeping the temperature of the above sodium humate solution at 35°C, under stirring conditions, add 4.8kg of ethylenediaminetetraacetic acid, and react for 36h;

[0025] S3. Cool to room temperature, add 3.24kg sodium hexametaphosphate and 6.48kg zinc sulfate, stir evenly, heat to 70°C, and react for 10h;

[0026] S4, be cooled to room temperature, filter, obtain filtrate, add 5.96kg of sodium hypochlorite to the filtrate, decolorize, promptly obtain colorless semi-finished product;

[0027] S5. Add 1.61 kg of hydroxyethylidene diphosphonic acid and 8.05 kg of polymaleic anhydride to the semi-finished product, and mix them evenly to obtain a water treatment agent.

Embodiment 2

[0029] A preparation method of a water treatment agent, comprising the steps:

[0030] S1, 10kg sodium humate is added to the reactor, then 80kg water is added in the reactor, heating and stirring makes the sodium humate completely dissolve;

[0031] S2. Keep the above sodium humate solution at a temperature of 60°C, add 5.4kg of EDTA under stirring conditions, and react for 24h;

[0032] S3. Cool to room temperature, add 19.08kg sodium hexametaphosphate and 9.54kg zinc sulfate, mix well, heat to 95°C, and react for 2h;

[0033] S4, cool to room temperature, filter, obtain filtrate, add 24.80kg of sodium hypochlorite to the filtrate, decolorize, promptly obtain colorless semi-finished product;

[0034] S5. Add 14.88kg of hydroxyethylidene diphosphonic acid and 2.98kg of polymaleic anhydride to the semi-finished product, and mix them evenly to obtain a water treatment agent.

Embodiment 3

[0036] A preparation method of a water treatment agent, comprising the steps:

[0037] S1, 10kg sodium humate is added to the reactor, then 30kg water is added in the reactor, heating and stirring makes the sodium humate completely dissolve;

[0038] S2, keeping the temperature of the above sodium humate solution at 40°C, under stirring conditions, add 0.8kg of ethylenediaminetetraacetic acid, and react for 6h;

[0039] S3. Cool to room temperature, add 4.08kg sodium hexametaphosphate and 1.22kg zinc sulfate, mix well, heat to 80°C, and react for 4h;

[0040] S4, cool to room temperature, filter, obtain filtrate, add 6.92kg of sodium hypochlorite to the filtrate, decolorize, promptly obtain colorless semi-finished product;

[0041] S5. Add 2.65kg of hydroxyethylidene diphosphonic acid and 2.65kg of polymaleic anhydride to the semi-finished product, and mix them evenly to obtain a water treatment agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com