A multi-layer radar absorbing coating

A wave-absorbing coating and radar technology, applied in the direction of radiation-absorbing coatings, electrical components, antennas, etc., can solve the problems of unacceptable stability and wave-absorbing effect, unsolved powder nanomaterial dispersion process, etc. The effect of absorption effect, widening frequency band, good temperature resistance and environmental stability

Active Publication Date: 2012-09-12

SOUTHWEST JIAOTONG UNIV

View PDF5 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

From the perspective of practical application, there are also two problems: one is that the dispersion process of powdered nanomaterials has not been solved, and the other is that the stability and absorbing effect have not yet been accepted.

But its material thickness is more than 3.5mm

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

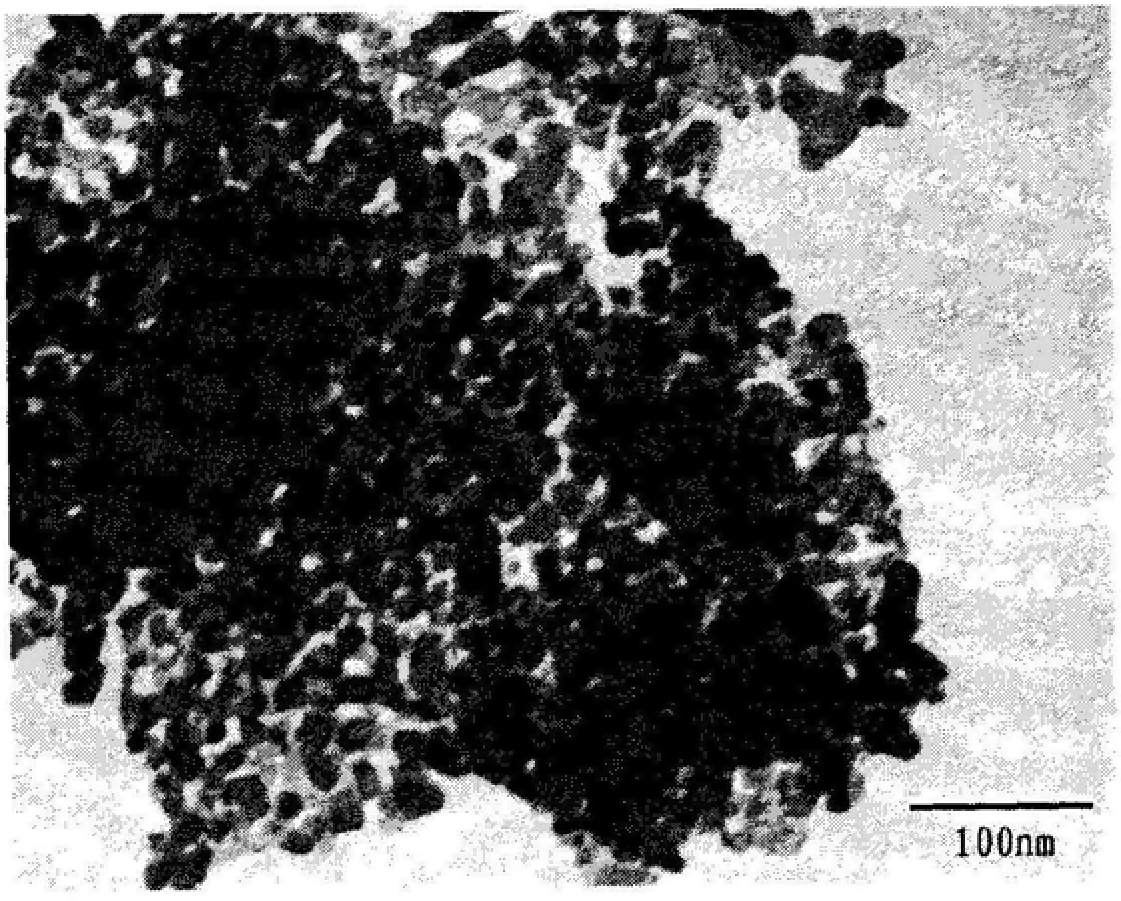

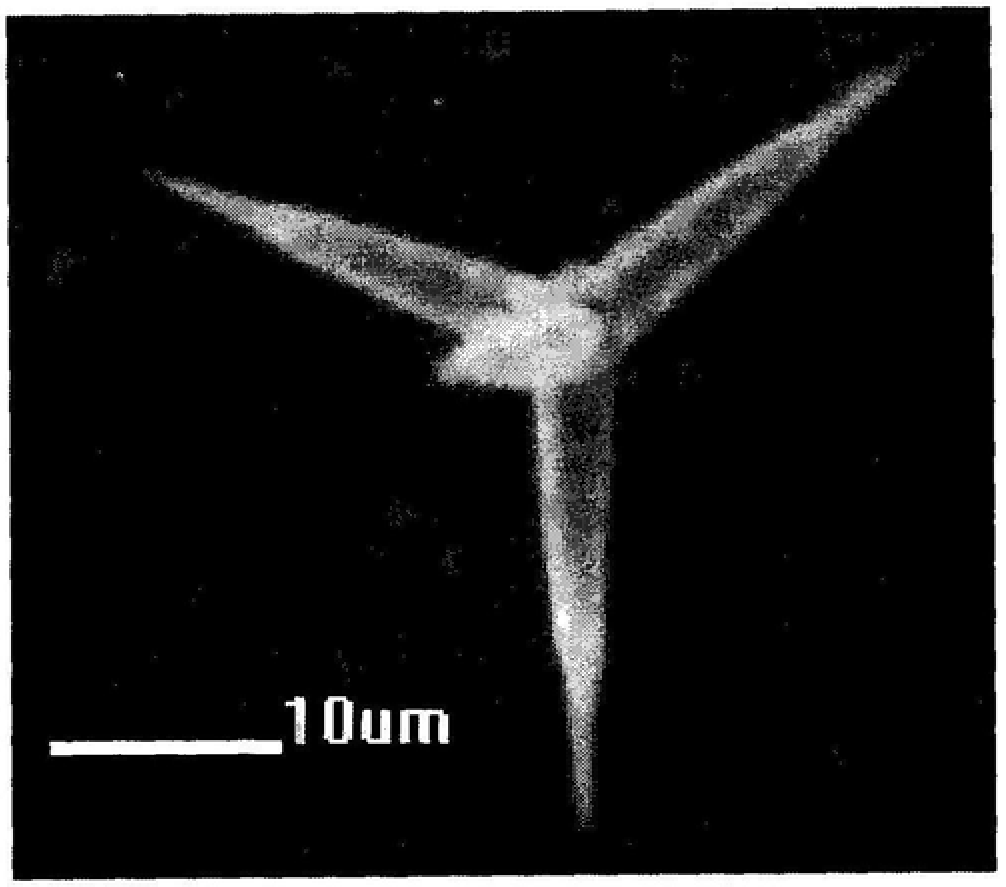

The invention provides a multi-layer radar absorbing coating and a preparation method thereof. The absorbing coating includes alternately superimposed dielectric loss composite coating layers and magnetic loss composite coating layers; the dielectric loss coating mainly includes four needle-shaped zinc oxide Whiskers, conductive carbon black; magnetic loss composite coating mainly includes ferric oxide and nano-iron powder; it is applied to the aluminum flat material by spraying or brushing, and the spraying sequence from the bottom layer to the surface layer is: magnetic layer - dielectric Layer - magnetic layer - dielectric layer..., the coating is cured at room temperature to obtain an absorbing coating. The total thickness of the coating is 1.5±0.1mm, and the thickness of each layer is evenly distributed. The reflectivity of the radar wave absorbing stealth coating of the present invention reaches -4~-6dB in the 4-8GHz band; the reflectivity in the 8-18GHz band reaches -5~-8dB. The surface density of the coating is about 1.6±0.2kg / m2, the adhesion reaches more than 13.5MPa, the impact strength reaches 50kg.cm, and it has good temperature resistance and environmental stability.

Description

A multi-layer radar absorbing coating technical field The invention relates to a wave-absorbing stealth material (RAM), in particular to a multi-layer radar wave-absorbing coating and a preparation method thereof. Background technique The development and application of stealth materials are considered to be a major breakthrough in the field of military high-tech. Modern stealth technology mainly includes the design and application of stealth structures and stealth materials. Advanced stealth materials play a pivotal role in the engineering application of stealth targets. They can be used not only to suppress specular waves, but also to suppress traveling waves, creeping waves, and edge-launched echoes. The radar wave absorption performance of materials is an important and key indicator of stealth materials and stealth technology; radar wave absorption performance refers to the ability of materials to attenuate the target echo intensity through the interaction with radar wa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01Q17/00C09D5/32

Inventor 周祚万胡书春陈晓浪

Owner SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com