Method for producing quick lime through brickmaking waste heat

A quicklime and waste heat technology, which is applied in lime production, ceramic material production, lighting and heating equipment, etc., can solve the problems of occupying brick space, long process time, and reducing brick production, so as to reduce heat energy emissions, increase economic benefits, reduce The effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

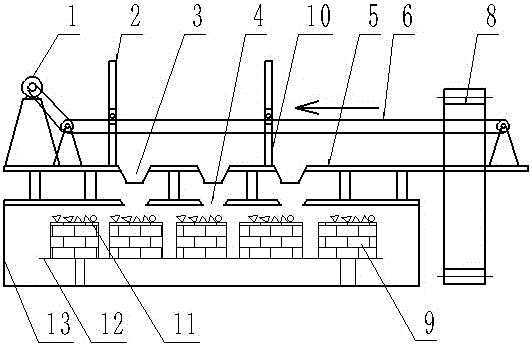

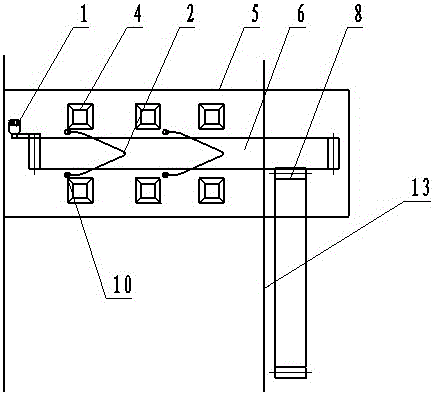

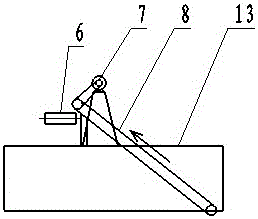

[0013] A method for producing quicklime by using brick-making waste heat of the present invention, the first step is to stack the bricks on the kiln car, and the number of stacks for each kiln car depends on the size of the kiln car. The kiln car used in the existing large-scale tunnel kiln can be Stack adobe stacks of 3x4 quantities. The second step is to push the kiln car with the adobe stacked into the tunnel kiln. The first thing to enter is the moisture removal section. This section has a temperature of 80-100°C and after 8-10 hours, the hot air will dehydrate the adobe to about 3-5%. The load-bearing capacity of the adobe is greatly increased. The kiln car then enters the preheating section. The top of the tunnel kiln in this section is provided with feeding holes corresponding to the distance between the piles of bricks on the kiln car. At the same time, a mineral material conveying system is set up on the top of the tunnel kiln. 20cm of limestone is paved on the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com