Fabrication method of low temperature poly-silicon array substrate, array substrate and display panel

A low-temperature polysilicon and array substrate technology, used in semiconductor/solid-state device manufacturing, gaseous chemical plating, coating, etc., can solve the problems of many processes, increase the cost and complexity of the manufacturing process, achieve uniform doping and reduce mask times, the effect of improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

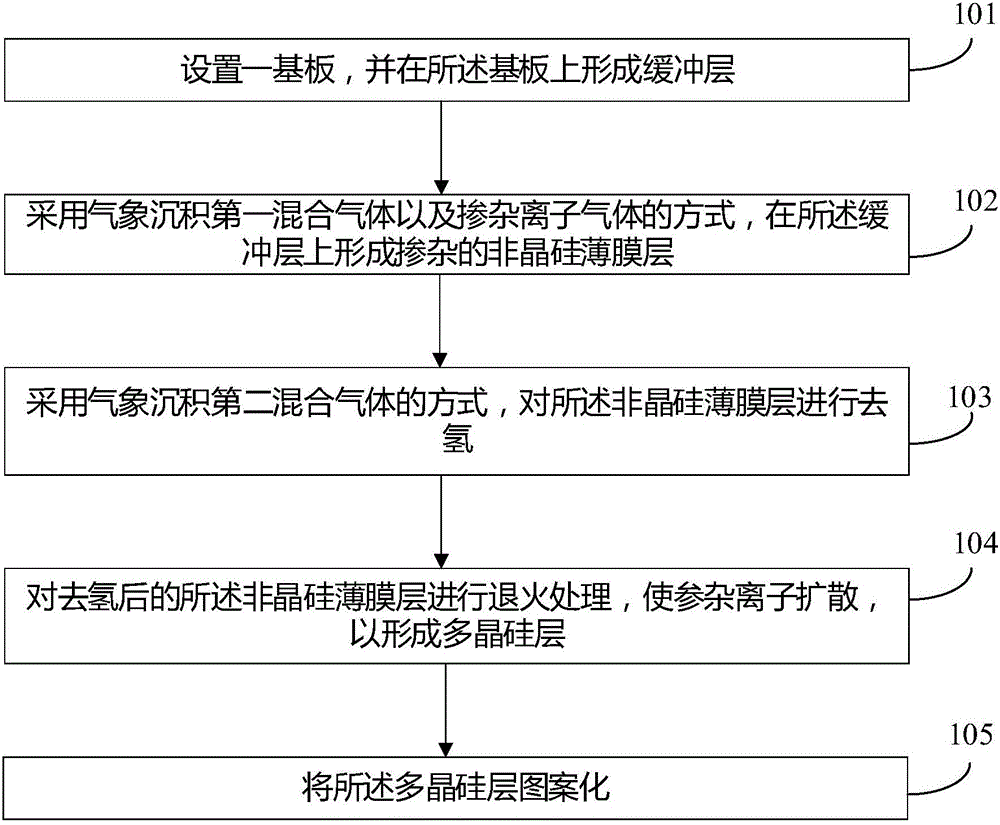

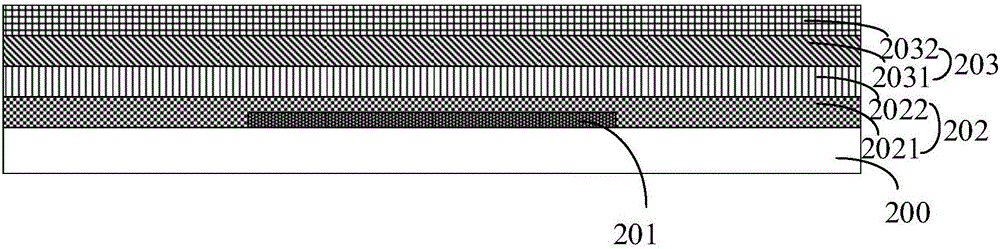

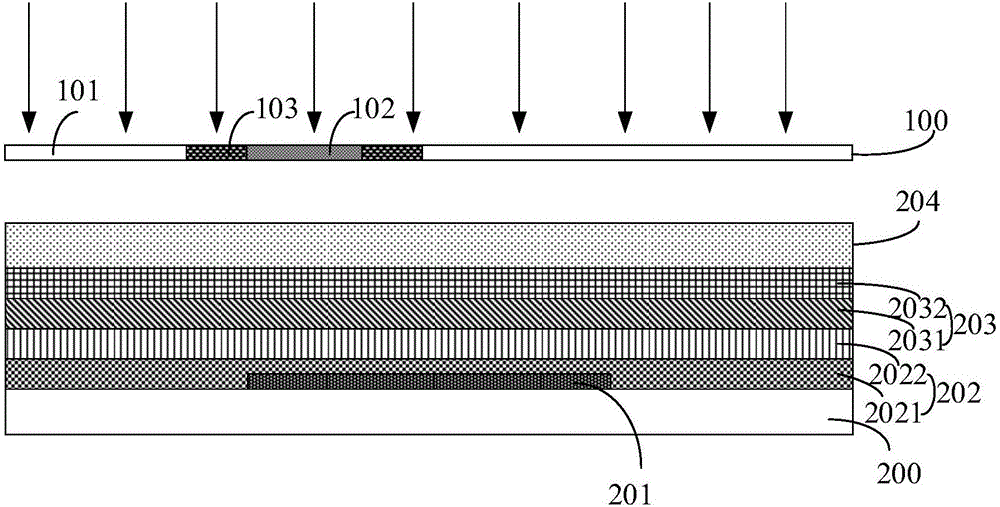

[0044] refer to figure 1 , figure 1 It is a schematic flow chart of an embodiment of the method for preparing a low-temperature polysilicon array substrate of the present invention. see also Figure 2A ~ Figure 2E The structure diagram of the corresponding low-temperature polysilicon array substrate, the manufacturing method of this embodiment includes the following steps:

[0045] 101 : Setting a substrate 200 and forming a buffer layer 202 on the substrate 200 .

[0046] Wherein, the substrate 200 includes a glass substrate, and may also be other substrates such as a quartz substrate in other embodiments, which is not limited here.

[0047] Specifically, first set the first substrate 200, first form the light-shielding layer 201 on the first substrate 200, then deposit the SiNx layer 2021 on the light-shielding layer, and then deposit the SiOx layer 2022 on the SiNx layer 2021, wherein the SiNx layer 2021 and the SiOx layer 2022 constitute the buffer layer 202 .

[0048...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com