Micro-channel regenerative cooling micro-combustor

A micro-combustion chamber, regenerative cooling technology, applied in the field of aero-engines, to achieve full combustion, improve wall temperature uniformity, and high flameout limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

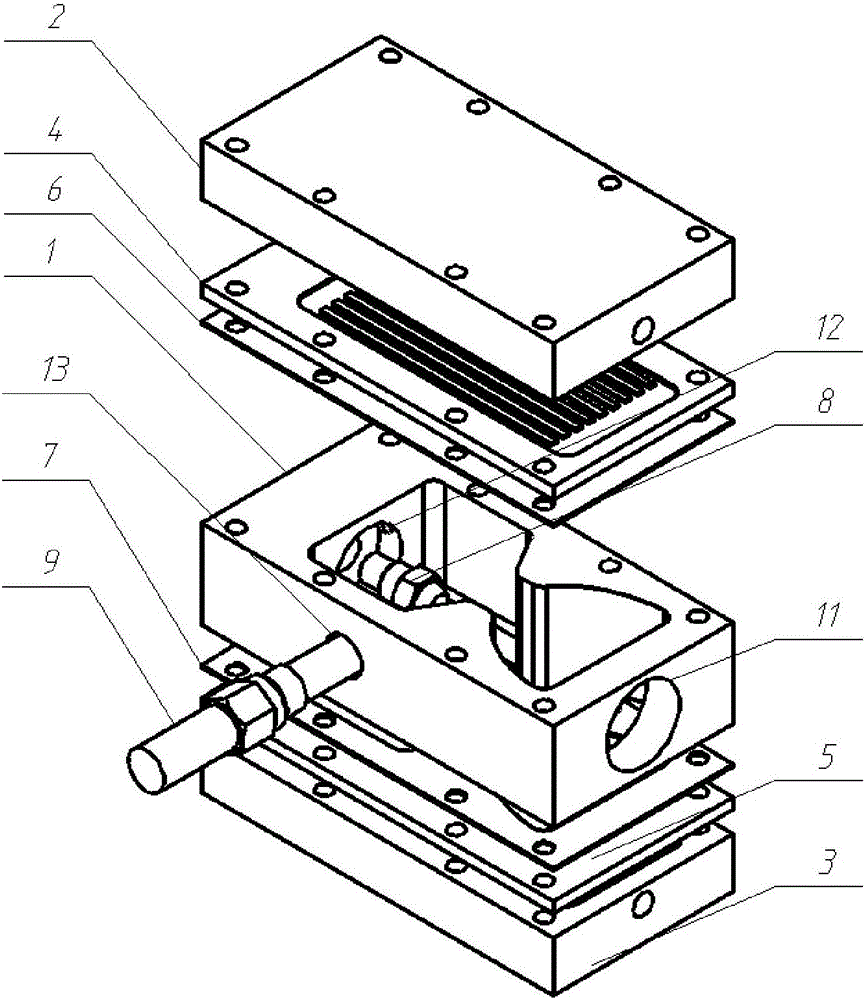

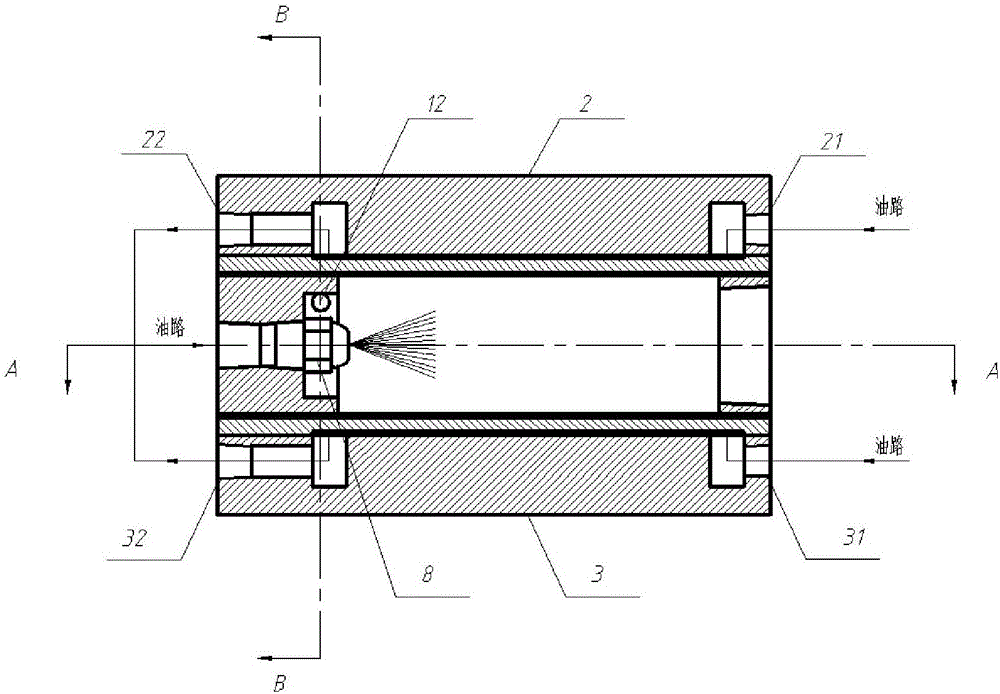

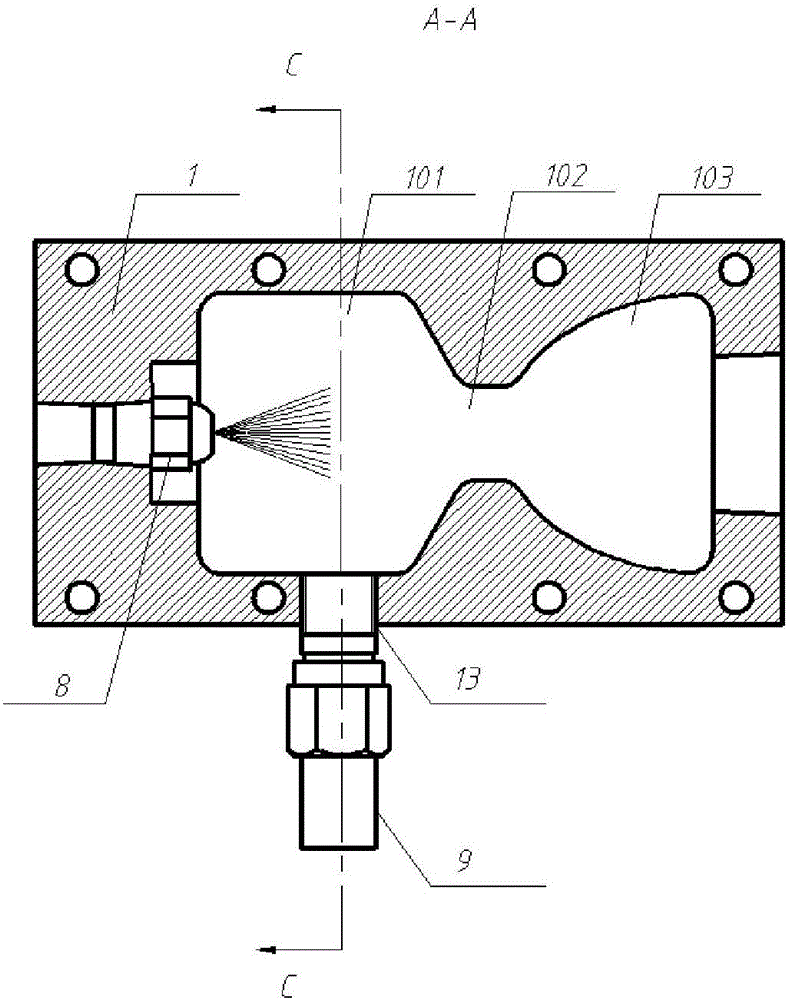

[0024] see figure 1 and figure 2 , a micro-combustor with micro-channel regenerative cooling, such as figure 1 As shown, it is composed of the combustion chamber (1) and the intermediate backing plates (6, 7) on the upper and lower sides, the microchannel plate (4, 5), and the top cover plate (2, 3) by stacking and combining , the combustion chamber (1), the middle backing plate (6, 7), and the microchannel plate (4, 5) form a closed combustion chamber, the front end of the combustion chamber (1) is provided with a fuel nozzle (8), and the rear end is exhaust gas The discharge port (11), the air inlet (12) is provided on one side of the wall, and the connection port (13) of the igniter (9) is provided on the other side; the front and rear ends of the top cover plates (2, 3) are respectively provided with fuel inlets (21, 31) and outlets (22, 32); the microchannel plate (4, 5) comprises 10-20 microchannels (41) arranged in parallel and equally spaced. During assembly, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center distance | aaaaa | aaaaa |

| Hydraulic diameter | aaaaa | aaaaa |

| Vertical width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com