Biogas plant and method for operating a biogas plant

A biogas and equipment technology, applied in biochemical equipment and methods, gas production bioreactors, biochemical instruments, etc., can solve the problems of heat loss in fermentation tanks, cost of biogas cooling utility, etc., and achieve effective thermal protection and good biogas cooling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

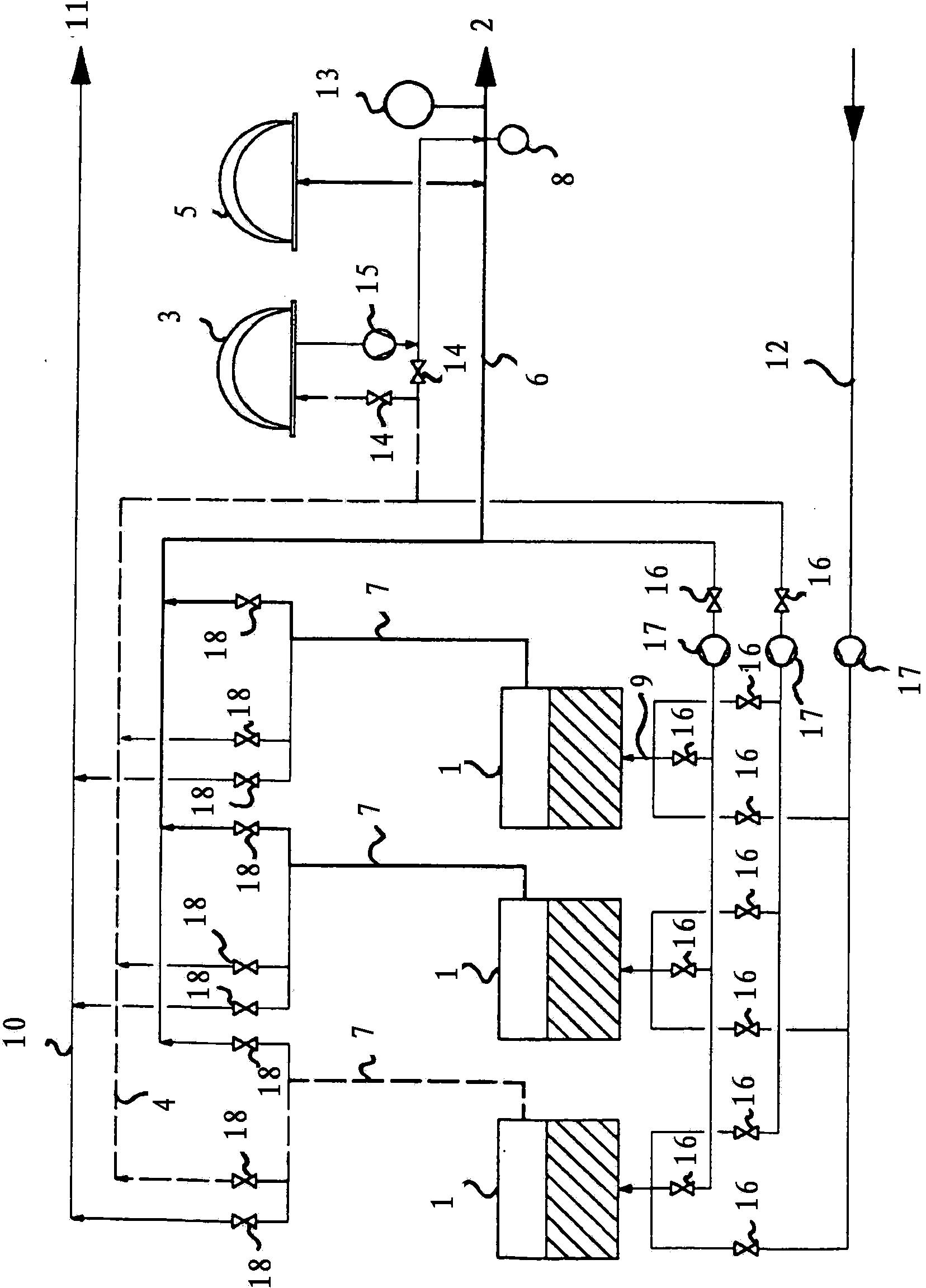

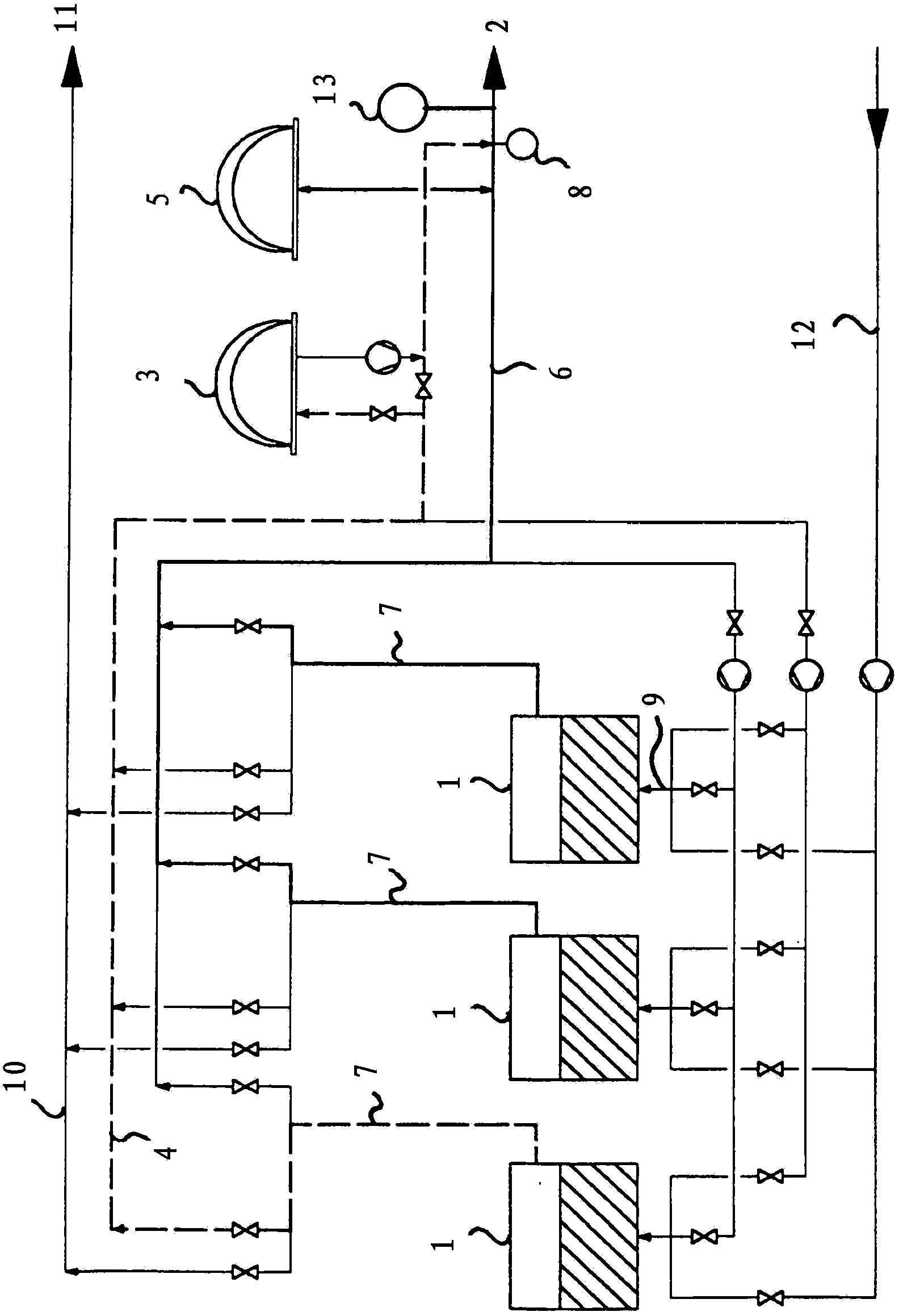

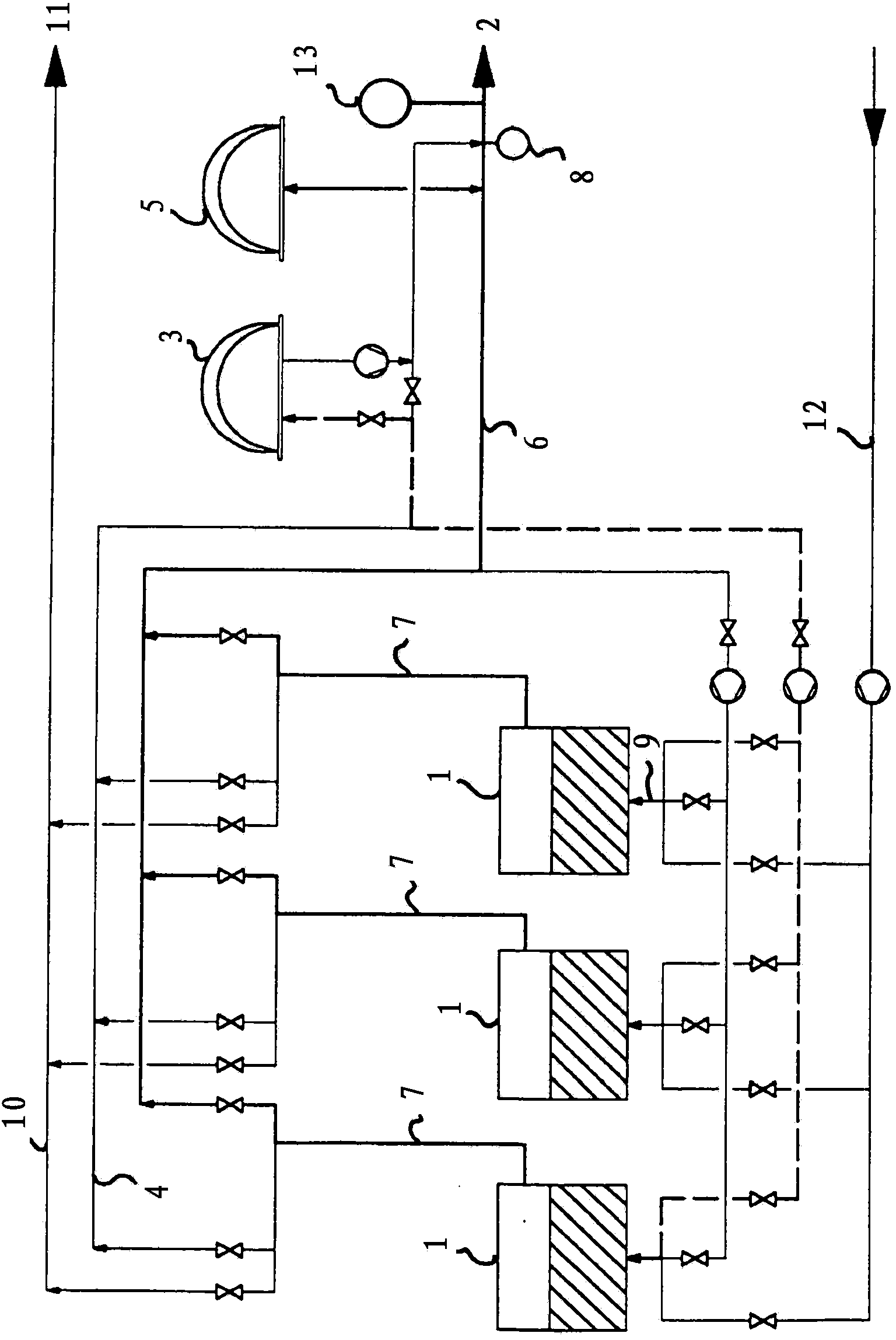

[0024] The exemplary biogas plant proposed by the present invention has three fermenters 1 that can be operated independently of each other, and these fermenters can all use their gas outlet 7 to selectively communicate with the first biogas conduit 4, the second biogas conduit 6 or an exhaust gas A conduit 10 is connected, which leads to an exhaust gas treatment point 11 . The biogas flows introduced into the biogas lines 4 and 6 can be mixed with one another or fed separately to a biogas utilization device 2 . The exemplary biogas plant proposed by the invention is equipped for this purpose with a control device 8 for mixing the two biogas streams. Furthermore, a measuring device 13 is provided, which measures the methane content of the biogas fed to the biogas utilization device 2 . The biogas line 4 is connected to the biogas storage 3 designed as a weak biogas storage. In this case, the biogas can be conveyed to or removed from the first biogas store 3 in a targeted man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com