Selective laser sintering based preparation method of complex-structure porous ceramic

A technology of laser selective sintering and porous ceramics, which is applied to ceramic products, other household utensils, household utensils, etc., can solve the problems of difficult controllable forming of high-complexity porous ceramics and preparation of complex porous ceramics, etc., to achieve large-scale adjustment Scope and controllability, reduced production cost, simple and efficient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The embodiment of the present invention provides a method for preparing porous ceramics with a complex structure based on selective laser sintering technology (Selective laser sintering, SLS), the steps of which include:

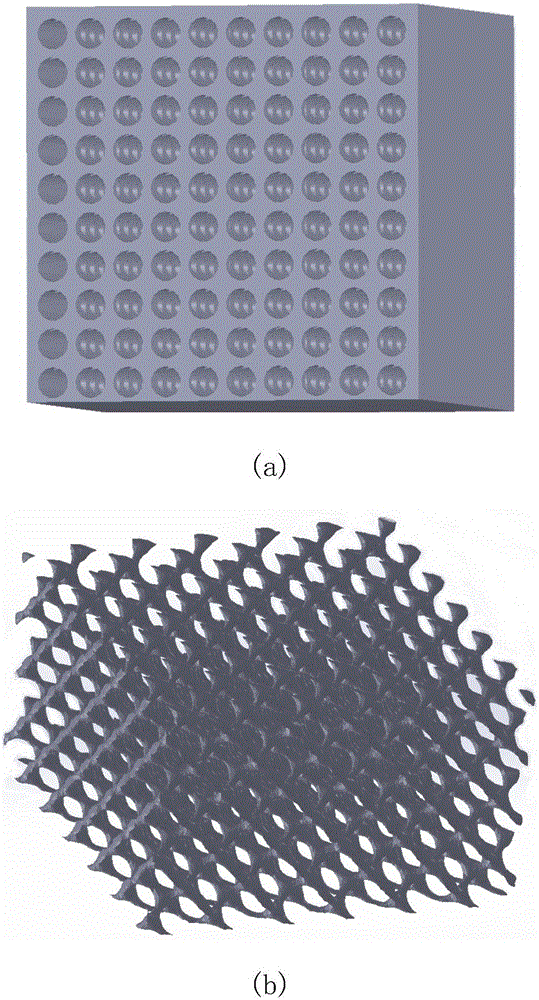

[0032] (1) Optimize the design of the CAD model of porous ceramics with complex structures according to the application requirements (that is, according to the use occasions and performance requirements of porous ceramics, optimize the design of the macroscopic porous structure, such as: increase or decrease the interconnected pore structure, the inner wall of the smooth hole Or adding special-shaped protrusions on the inner wall of the hole), sliced by the slicing software and saved as an STL file, and the data information of the STL file is imported into the SLS molding equipment, wherein the CAD 3D model can be optimized according to the application requirements. Honeycomb porous structure with interconnecting holes or spatial topological structur...

Embodiment 1

[0045] (1) Establish a part CAD model with a honeycomb porous structure with internal connectivity (see figure 1 ), which is processed by slicing software and saved as an STL file, and the data information of the STL file is imported into the SLS forming equipment;

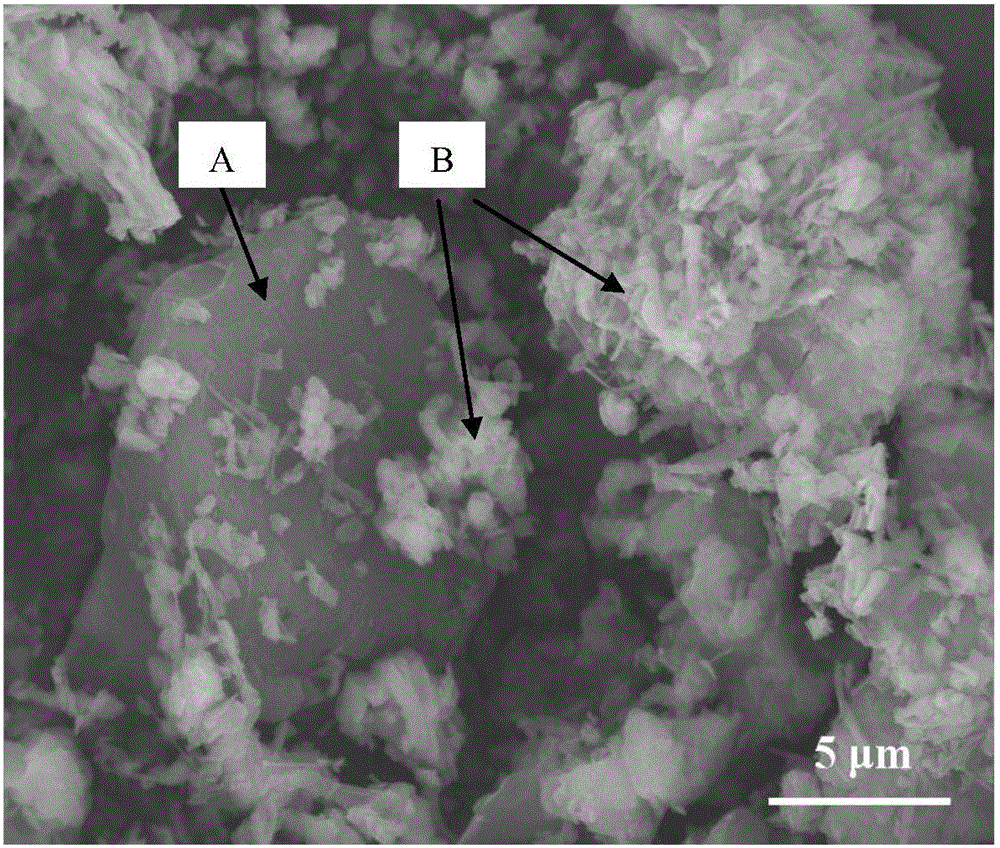

[0046] (2) Take 300g Si 3 N 4 Add 15.79g, 33.33g, 52.94g, 75.00g, and 100.00g of epoxy resin E12 to the granulated powder, mix them evenly in a nylon tank, and rotate on the powder mixing rack for 24 hours to obtain E12 with a content of 5wt%, 10wt%. , 15wt%, 20wt%, 25wt% E12 / Si 3 N 4 Composite powder (see figure 2 , figure 2 Among them, A is ceramic powder, B is epoxy resin);

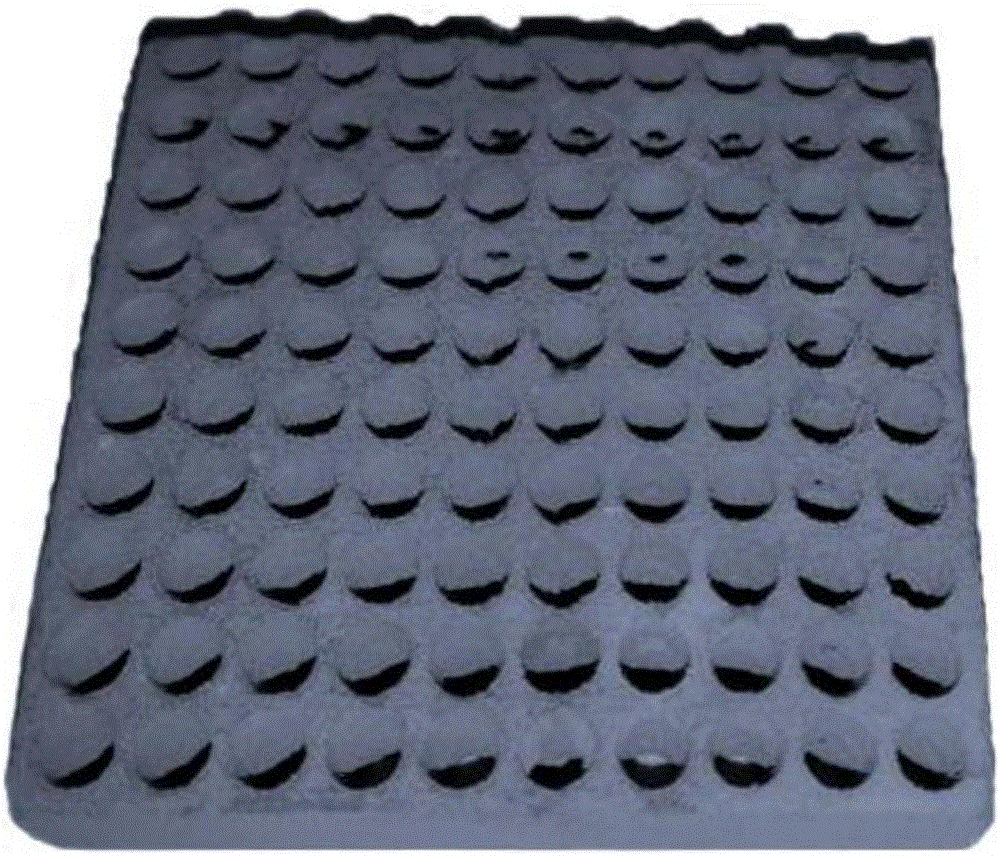

[0047] (3) Form the above composite powder on SLS equipment, the laser spot diameter is 0.15mm, the preheating temperature is 45°C, the powder layer thickness is 0.15mm, the scanning distance is 0.15mm, the laser power is 9W, and the scanning speed is 2000mm / s (formed biscuit such as image 3 As shown, the microscopic morphology...

Embodiment 2

[0051] (1) Establish a CAD model of the octahedron space topology, and save it as an STL file after being processed by the slicing software, and import the data information of the STL file into the SLS forming equipment;

[0052] (2) Take 300g of SiC granulation powder for each group and add 15.79g, 33.33g, 52.94g, 75.00g, 100.00g of epoxy resin E12 into a nylon tank and mix evenly, and rotate it on the powder mixing rack for 24 hours to obtain the content of E12 5wt%, 10wt%, 15wt%, 20wt%, 25wt% E12 / SiC composite powder;

[0053] (3) Form the above composite powder on SLS equipment, the laser spot diameter is 0.2mm, the preheating temperature is 45°C, the powder layer thickness is 0.2mm, the scanning distance is 0.2mm, the laser power is 5W, and the scanning speed is 1000mm / s;

[0054] (4) Place the biscuit in the debinding furnace, raise the temperature to 600°C at a rate of 1°C / min, keep it warm for 2 hours, and cool with the furnace;

[0055] (5) Place the degummed green...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com