Anti-crack mortar and preparation method thereof

A technology for crack-resistant mortar and a manufacturing method, applied in the field of construction mortar, can solve the problems of easy cracking and low strength of crack-resistant mortar, and achieve the effects of not easy to hollow out, excellent thermal insulation and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

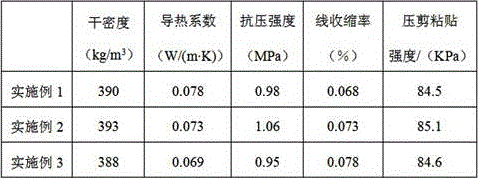

Embodiment 1

[0012] The anti-crack mortar in this example is prepared from the following raw materials in parts by weight: 30 parts of lightweight aggregate, 25 parts of cement, 10 parts of talcum powder, 5 parts of wollastonite, 6 parts of asbestos powder, 3 parts of nut shells, diatoms 7 parts of soil, 3 parts of phenolic resin, 3 parts of polyester fiber, and 3 parts of anti-cracking agent; wherein, the anti-cracking agent is a mixture of vegetable oil, carbon fiber and epoxy resin, wherein the quality of vegetable oil, carbon fiber and epoxy resin is one The ratio is 1:4:2; the lightweight aggregate is expanded perlite.

[0013] In this embodiment, the carbon fiber has a diameter of 10 microns and a length of 5 nanometers.

[0014] The preparation method of the anti-cracking mortar in this embodiment is as follows: add lightweight aggregate, cement, talcum powder, wollastonite, asbestos powder, nut shells and diatomaceous earth into the pulverizer for grinding, and adjust the rotating ...

Embodiment 2

[0017] The anti-crack mortar in this example is prepared from the following raw materials in parts by weight: 35 parts of lightweight aggregate, 20 parts of cement, 13 parts of talcum powder, 7 parts of wollastonite, 2 parts of asbestos powder, 5 parts of nut shells, diatoms 10 parts of soil, 1 part of phenolic resin, 2 parts of polyester fiber, and 2 parts of anti-cracking agent; wherein, the anti-cracking agent is a mixture of vegetable oil, carbon fiber and epoxy resin, wherein the quality of vegetable oil, carbon fiber and epoxy resin is one The ratio is 1:3:4; the lightweight aggregate is volcanic slag.

[0018] In this embodiment, the carbon fiber has a diameter of 7 microns and a length of 3 nanometers.

[0019] The preparation method of the anti-cracking mortar in this embodiment is as follows: add lightweight aggregate, cement, talcum powder, wollastonite, asbestos powder, nut shells and diatomaceous earth into the pulverizer for grinding, and adjust the rotating spee...

Embodiment 3

[0022] The anti-crack mortar in this example is prepared from the following raw materials in parts by weight: 40 parts of lightweight aggregate, 23 parts of cement, 15 parts of talcum powder, 10 parts of wollastonite, 4 parts of asbestos powder, 4 parts of nut shells, diatoms 15 parts of soil, 2 parts of phenolic resin, 5 parts of polyester fiber, and 4 parts of anti-cracking agent; wherein, the anti-cracking agent is a mixture of vegetable oil, carbon fiber and epoxy resin, wherein the quality of vegetable oil, carbon fiber and epoxy resin is one The ratio is 1:5:6; the lightweight aggregate is volcanic slag.

[0023] In this embodiment, the carbon fiber has a diameter of 5 micrometers and a length of 8 nanometers.

[0024] The preparation method of the anti-cracking mortar in this embodiment is as follows: add lightweight aggregate, cement, talcum powder, wollastonite, asbestos powder, nut shells and diatomaceous earth into the pulverizer for grinding, and adjust the rotatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com