Ozone-ultra-micron air bubble-filtering system and ozone-ultra-micron air bubble-filtering method

A filtration method and filtration system technology, applied in the fields of filtration treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problems of large area occupied by structures, short hydraulic retention time, low oxygen transfer rate, etc., and achieve long-term Stable operation, no secondary pollution, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

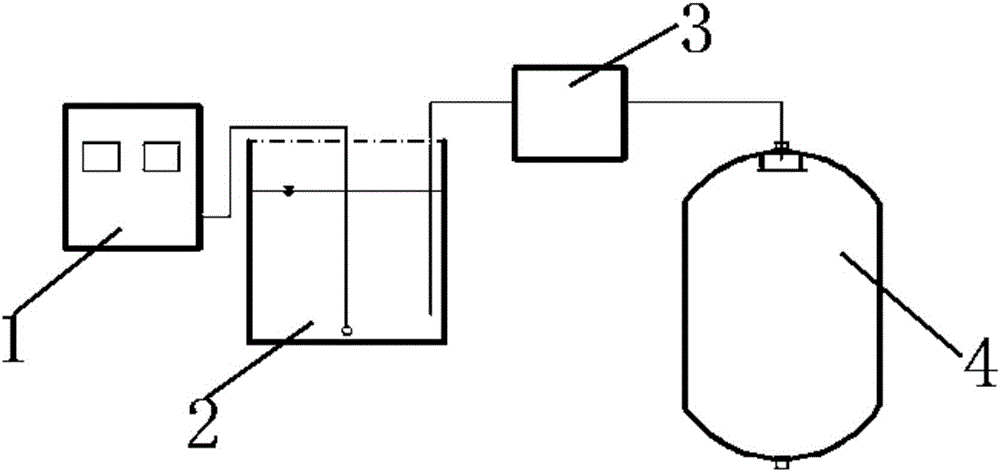

[0025] The application principle of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

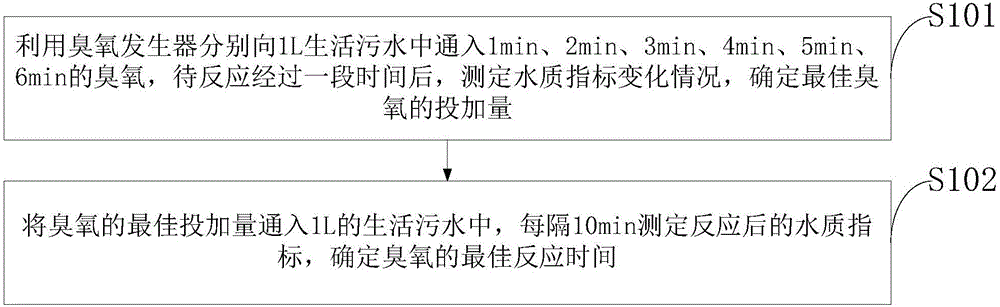

[0026] Such as figure 1 As shown, the method for controlling the dosage of ozone to find the optimal dosage of ozone by controlling the time that the ozone generator produces ozone provided by the embodiment of the present invention includes the following steps:

[0027] S101: Use an ozone generator to inject ozone into 1L of domestic sewage for 1min, 2min, 3min, 4min, 5min, and 6min respectively, and after a period of reaction, measure the changes in water qual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com