Preparation method of high-purity heat-conducting spherical aluminum oxide

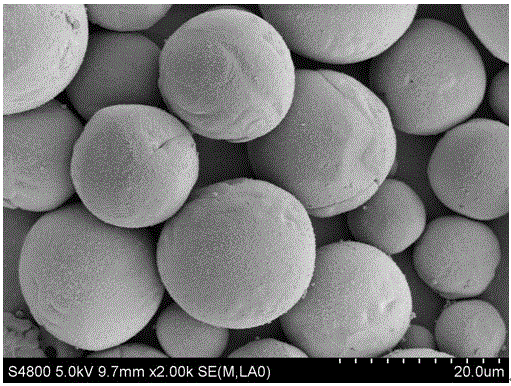

A spherical alumina, high-purity alumina technology, used in aluminate/alumina/aluminum hydroxide purification, epoxy resin glue, non-polymer adhesive additives, etc., can solve physical structure and performance limitations, The surface of alumina is not smooth, which affects the thermal conductivity of the product, etc., to achieve the effect of adjustable powder particle size, small powder particle size and good sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

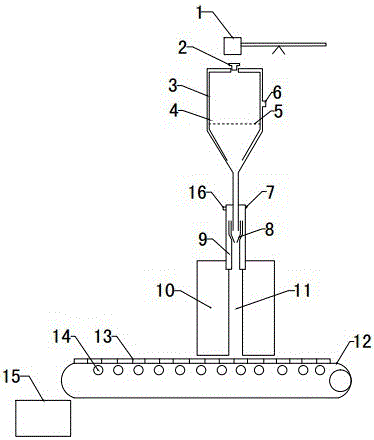

Method used

Image

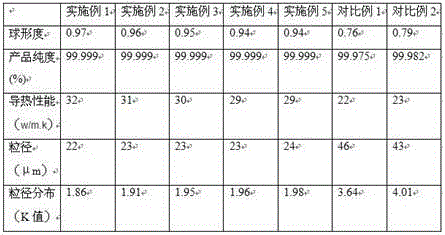

Examples

Embodiment 1

[0035] 1) First put the carrier made of high-purity alumina on the conveyor belt, and align it with the discharge hole of the furnace, and start the cooling water under the conveyor belt;

[0036] 2) Put high-purity gamma alumina powder with particle size D50: 30 microns into the inner hopper;

[0037] 3) Connect the hydrogen-oxygen burner to the gas supply device and ignite it, adjust the hydrogen to 300SLM, the oxygen flow to 140SLM, and start heating up the kiln;

[0038] 4) When the temperature in the furnace rises to 1875°C, open the discharge port of the hopper, start the vibrating hammer above the hopper, and set the frequency of the vibrating hammer to 12HZ and the air intake of the loaded oxygen to 25SLM, so that the high-purity alumina powder Evenly and stably pass through the oxygen nozzle, enter the hydrogen-oxygen mixed combustion chamber, and carry out sintering, the feeding speed is 2000g / h;

[0039] 5) After the material is sintered by the hydrogen-oxygen flame ...

Embodiment 2

[0041] 1) First put the carrier made of high-purity alumina on the conveyor belt, align it with the discharge hole of the furnace, and start the cooling water under the conveyor belt;

[0042] 2) Put the high-purity gamma alumina powder with particle size D50: 28 microns into the inner hopper;

[0043] 3) Connect the hydrogen-oxygen burner to the gas supply device and ignite it, adjust the hydrogen gas to 296SLM, the oxygen flow rate to 140SLM, and start heating up the kiln;

[0044] 4) When the temperature in the furnace rises to 1865°C, open the discharge port of the hopper, start the vibrating hammer above the hopper, and set the frequency of the vibrating hammer to 11.5HZ and the air intake of the loaded oxygen to 25.6SLM, so that the high-purity Alumina powder passes through the oxygen nozzle evenly and stably, enters the hydrogen-oxygen mixed combustion chamber, and is sintered at a feeding rate of 1995g / h;

[0045] 5) After the material is sintered by the hydrogen-oxyg...

Embodiment 3

[0047] 1) First put the carrier made of high-purity alumina on the conveyor belt, align it with the discharge hole of the furnace, and start the cooling water under the conveyor belt;

[0048] 2) Put the high-purity gamma alumina powder with particle size D50: 32 microns into the inner hopper;

[0049] 3) Connect the hydrogen-oxygen burner to the gas supply device and ignite it, adjust the hydrogen gas to 304SLM at 14.6~15.4:7, and the oxygen flow rate to 140SLM, and start heating up the kiln;

[0050] 4) When the temperature in the furnace rises to 1880°C, open the discharge port of the hopper, start the vibrating hammer above the hopper, and set the frequency of the vibrating hammer to 12.5HZ and the air intake of the loaded oxygen to 24.6SLM, so that the high-purity Alumina powder passes through the oxygen nozzle evenly and stably, enters the hydrogen-oxygen mixed combustion chamber, and is sintered at a feeding rate of 2005g / h;

[0051] 5) After the material is sintered b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com