Deep carbonation method for thick and heavy wood plate

A technology for wood panels and boards, applied in wood processing, wood processing appliances, wood processing details, etc., can solve the problems that are rarely seen, the crack resistance affects the use value, the crack resistance, and the bending resistance decline, etc., and the processing time is long Shorten, reduce adverse effects, and improve the effect of promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

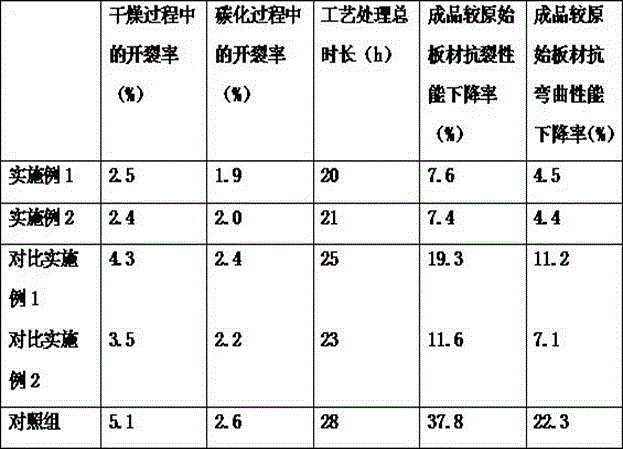

Examples

Embodiment 1

[0028] A kind of deep carbonization method of heavy wooden plank, comprises the steps:

[0029] (1) Wood cutting:

[0030] Cut the wood board to be processed according to the requirements of the processing design, and then rinse the sawdust and other impurities with clean water for later use;

[0031] (2) Wood pre-drying treatment:

[0032] Put the wooden boards treated in step (1) into a drying kiln, and dry the water content to 18-20% for later use;

[0033] (3) Deep drying treatment:

[0034] 1) Continue to dry the wooden board after step (2), keep the temperature in the drying kiln at 105°C, increase the pressure in the drying kiln to 1MPa, and apply ultrasonic waves with a frequency of 53KHz to the wooden board , until the water content of the board is dry to 12~13%;

[0035] 2) Continue to dry the board after operation 1). At this time, the temperature in the drying kiln is raised to 130°C, the pressure is raised to 1.8MPa, and the ultrasonic frequency is raised to 5...

Embodiment 2

[0048] A kind of deep carbonization method of heavy wooden plank, comprises the steps:

[0049] (1) Wood cutting:

[0050] Cut the wood board to be processed according to the requirements of the processing design, and then rinse the sawdust and other impurities with clean water for later use;

[0051] (2) Wood pre-drying treatment:

[0052] Put the wooden boards treated in step (1) into a drying kiln, and dry the water content to 18-20% for later use;

[0053] (3) Deep drying treatment:

[0054] 1) Continue to dry the board after step (2), keep the temperature in the drying kiln at 115°C, increase the pressure in the drying kiln to 1.5MPa, and apply ultrasonic waves with a frequency of 55 KHz to the board Treat until the water content of the board is dry to 13~14%;

[0055] 2) Continue to dry the board after operation 1). At this time, the temperature in the drying kiln is raised to 135°C, the pressure is raised to 2.2MPa, and the ultrasonic frequency is raised to 61KHz un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com