Preparation method of hydrogenation catalyst for slurry bed of heavy oil as well as catalyst and application thereof

A hydrogenation catalyst, slurry bed technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the complex catalyst preparation process, complex operation process, etc. The problem is to reduce the risk of re-oxidation, the operation steps are simple, and the dispersion performance is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

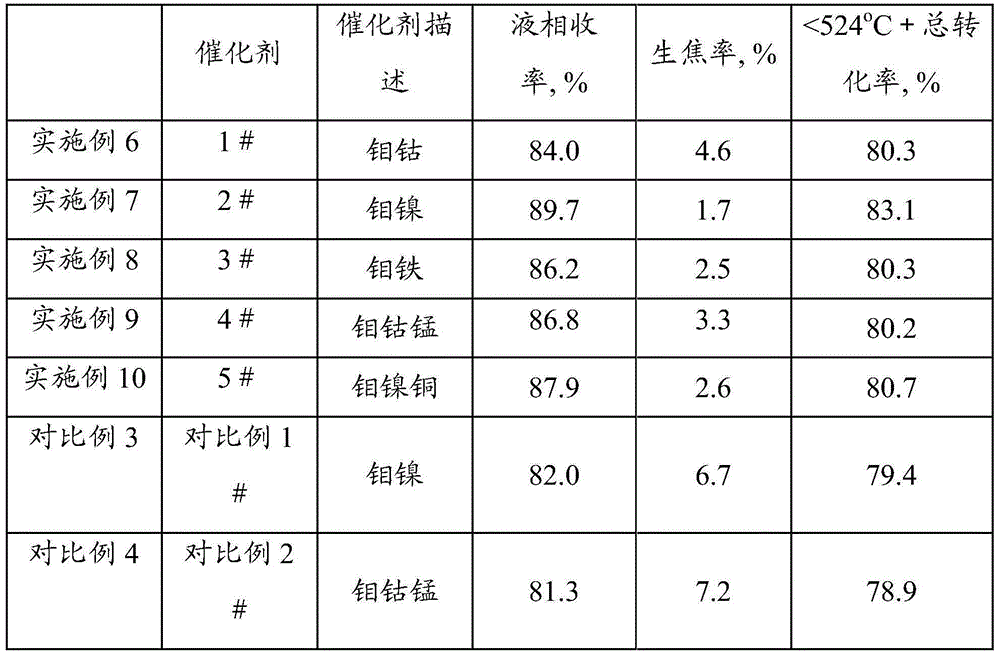

Examples

Embodiment 1

[0041] Weigh 5.73g of molybdenum trioxide in a beaker, add 8.20g of 25% ammonia solution and dissolve it under stirring to obtain solution A; add 11.60g of cobalt nitrate hexahydrate in the beaker, add 15ml of deionized water and dissolve to obtain solution B; in the beaker Add 20.10g of oxalic acid and dissolve it with 20ml of deionized water to obtain aqueous solution C; add B dropwise to aqueous solution A and mix well; then add dropwise C to the above mixed solution and stir until the solution is clear; then transfer the above solution to 500ml high pressure Add 2.00 g of sublimed sulfur powder to the stirred tank, seal the autoclave, and replace it with hydrogen 3 times; the pressure is filled to 1.0 MPa. Under high-speed stirring, heat the autoclave to 310℃±5℃, keep it at this temperature for 30 minutes, and then stop heating. After the autoclave is lowered to room temperature, the pressure is relieved and the autoclave is opened, the obtained slurry is transferred to a c...

Embodiment 2

[0043] Weigh 4.93g of ammonium molybdate in a beaker, add 25ml of deionized water and dissolve it under stirring to obtain solution A; add 8.11g of nickel nitrate to the beaker and add 10ml of deionized water to dissolve to obtain solution B; add 14.50g of oxalic acid to the beaker , Dissolve with 15ml of deionized water to obtain aqueous solution C; add B dropwise to aqueous solution A and mix evenly; then add dropwise C to the above mixed solution and stir until the solution is clear; transfer the above solution to a 500ml high-pressure stirred tank and add Sodium sulfide 15.20g, seal the autoclave, replace with hydrogen 3 times; pressurize to 1.5MPa. Under high-speed stirring, heat the autoclave to 310℃±5℃, keep it at this temperature for 30 minutes, and then stop heating. After the autoclave is lowered to room temperature, the pressure is relieved and the autoclave is opened, the obtained slurry is transferred to a centrifuge tube, centrifuged, and the upper aqueous solutio...

Embodiment 3

[0045] Weigh 5.65g of ammonium molybdate into a beaker, add 30ml of deionized water and dissolve it under stirring to obtain solution A; add 8.62g of ferric nitrate to the beaker, and add 10ml of deionized water to dissolve to obtain solution B; add g of oxalic acid to the beaker, Dissolve with g deionized water to obtain aqueous solution C; add B dropwise to aqueous solution A and mix uniformly; then drop C into the above mixed solution and stir until the solution is clear; transfer the above solution to a 500ml high-pressure stirred tank, and add sublimation Sulfur powder 2.90g, seal the autoclave, replace with hydrogen 3 times; pressurize to 1.5MPa. Under high-speed stirring, heat the autoclave to 310℃±5℃, keep it at this temperature for 30 minutes, and then stop heating. After the autoclave is lowered to room temperature, the pressure is relieved and the autoclave is opened, the obtained slurry is transferred to a centrifuge tube, centrifuged, and the upper aqueous solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com