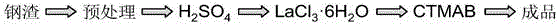

Preparation method of water body molybdate adsorbent based on solid waste steel slag

A solid waste, molybdate technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc. Inexpensive, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

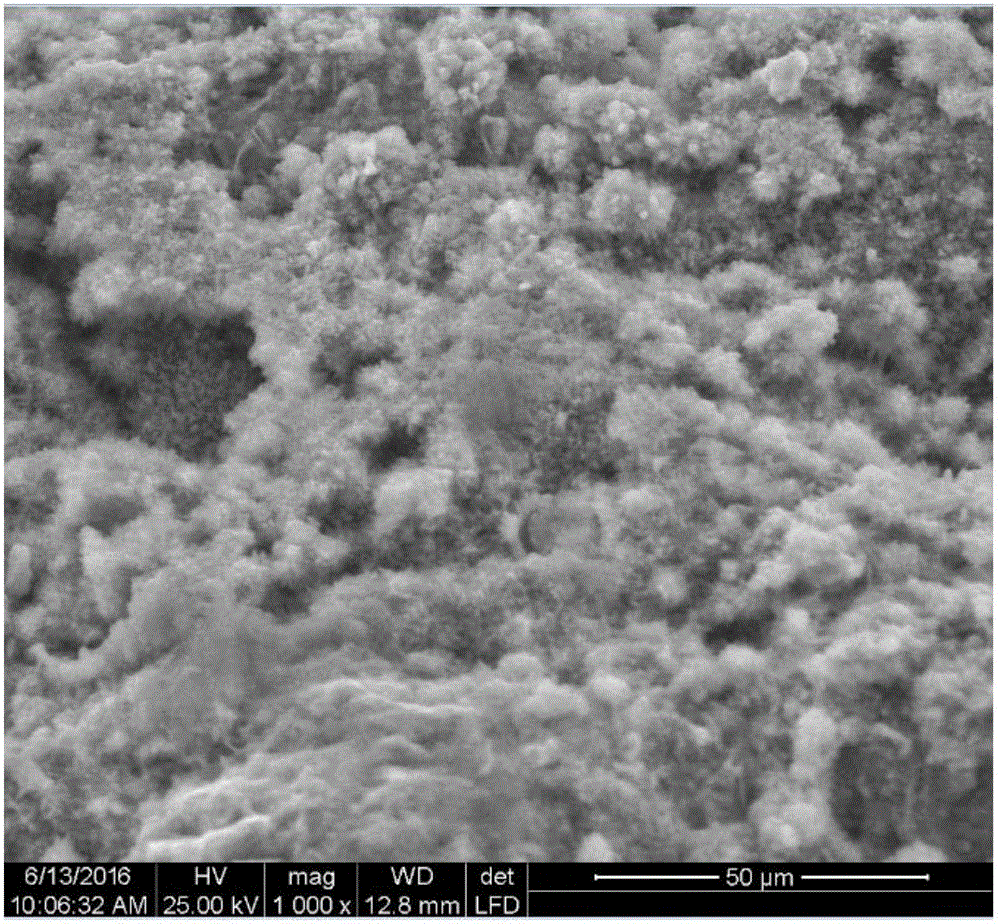

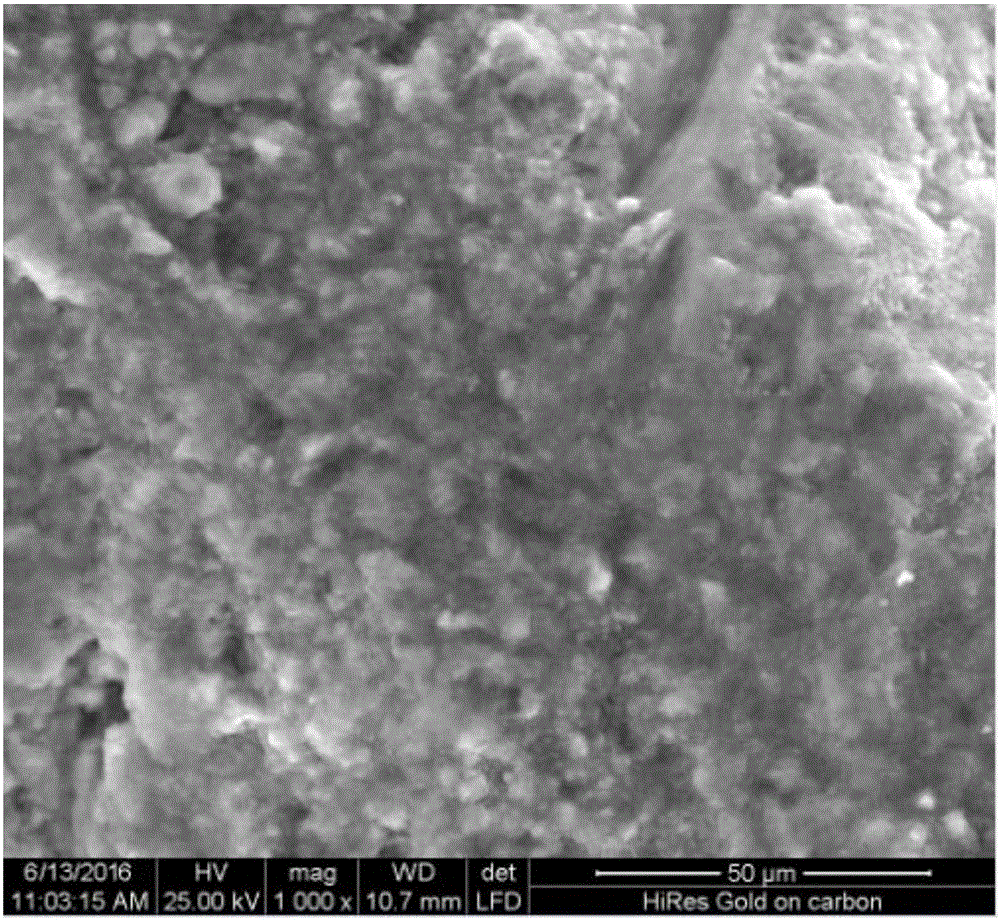

[0035] Put the desulfurized steel slag into clean water and rinse for 2 days, then grind, rinse, dry naturally, and screen to obtain 20g of steel slag with a particle size below 0.15mm. 1.0mol / L of H 2 SO 4 Add 50mL of the solution to the above steel slag, vibrate for 10h at a vibration speed of 200r / min, and then wash with water until it does not contain SO 4 2- , air-dried for later use; take 10 g of the above solid and put it into a 500 mL Erlenmeyer flask, and add it to 0.01 mol / L LaCl 3 ·6H 2 In 200mL of O solution, seal the Erlenmeyer flask and place it in a constant temperature oscillator at 35°C, shake at a speed of 200r / min for 2h, filter and collect the solid material; add the solid material to 200mL of 0.02mol / L CTMAB solution shake in a water bath at 25°C for 13 hours, filter and wash with deionized water until neutral, and dry the solid material in an oven at 100°C to obtain La-CTMAB modified steel slag 1.

Embodiment 2

[0037] Put the desulfurized steel slag into clean water and rinse for 2 days, then grind, rinse, dry naturally, and screen to obtain 20g of steel slag with a particle size below 0.15mm. 3.0mol / L of H 2 SO 4 Add 50mL of the solution to the above steel slag, vibrate for 8 hours at a vibration speed of 200r / min, and then wash with water until no SO 4 2- , air-dried for later use; take 10 g of the above solid and put it into a 500 mL Erlenmeyer flask, and add 0.01 mol / L LaCl 3 ·6H 2 O solution 200mL, seal the Erlenmeyer flask and place it in a constant temperature oscillator at 35°C, shake at a speed of 200r / min for 2h, filter and collect the solid material; add the solid material to 200mL of 0.03mol / L CTMAB solution , shake in a water bath at 30°C for 12h, filter and wash with deionized water until neutral, and dry the solid material in an oven at 100°C to obtain La-CTMAB modified steel slag 2.

Embodiment 3

[0039] Put the desulfurized steel slag into clean water and rinse for 2 days, then grind, rinse, dry naturally, and screen to obtain 20g of steel slag with a particle size below 0.15mm. 3.0mol / L of H 2 SO 4 Add 50mL of the solution to the above steel slag, vibrate for 8 hours at a vibration speed of 200r / min, and then wash with water until no SO 4 2- , air-dried for later use; take 10 g of the above solid into a 500 mL Erlenmeyer flask, and add 0.03 mol / L of LaCl 3 ·6H 2 O solution 200mL, seal the Erlenmeyer flask and place it in a constant temperature oscillator at 35°C, shake at a speed of 200r / min for 2h, filter and collect the solid material; add the solid material to 200mL of 0.04mol / L CTMAB solution , shaken in a water bath at 45°C for 15h, filtered, washed with deionized water until neutral, and dried in an oven at 100°C to obtain La-CTMAB modified steel slag 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com