Method for preparing natural friction agent by utilizing macadimia nut shell

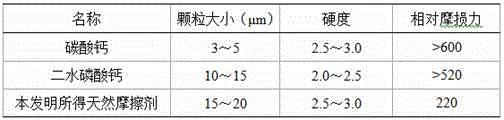

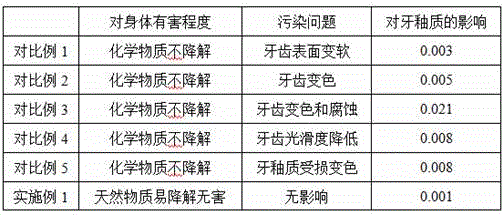

A technology of nut shells and friction agents, applied in the field of natural product reuse, to achieve stable chemical properties and less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Crush macadamia nut shells to a fine powder that passes through a 20-mesh sieve;

[0020] (2) The ratio of material to liquid L / L is calculated as 1:7, the fine powder obtained in step (1) is soaked in petroleum ether for 5 hours, after suction filtration, soaked repeatedly 4 times, and the filter residue is dried at 70°C for 2 hours to obtain Defatted Macadamia Nut Shell Powder;

[0021] (3) According to the material-to-liquid ratio L / L, it is 1:40. Add sodium hypochlorite with a concentration of 40wt% to the defatted macadamia nut shell powder obtained in step (2), and use ultrasonic-assisted extraction to decolorize for 25 minutes, repeat 4 times, and filter , discarding the filtrate, collecting the filter residue and drying at 70° C. for 2 hours to obtain decolorized macadamia nut shell powder;

[0022] (4) Superfinely pulverizing the decolorized macadamia nut shell powder obtained in step (3) to a particle size of 15-20 μm, to obtain a crude macadamia nut shel...

Embodiment 2

[0026] (1) Crush macadamia nut shells to a fine powder that passes through a 20-mesh sieve;

[0027] (2) According to the material-to-liquid ratio L / L as 1:5, the fine powder obtained in step (1) was soaked in n-hexane for 4 hours, then soaked repeatedly for 3 times after suction filtration, and the filter residue was dried at 60°C for 1.5h. Obtaining defatted macadamia nut shell powder;

[0028] (3) According to the material-to-liquid ratio L / L, it is 1:30. Add hydrogen peroxide with a concentration of 10wt% to the defatted macadamia nut shell powder obtained in step (2), and use ultrasonic-assisted extraction to decolorize for 20 minutes, repeat 3 times, and filter , discarding the filtrate, collecting the filter residue and drying at 60° C. for 1.5 h to obtain decolorized macadamia nut shell powder;

[0029] (4) Superfinely pulverizing the decolorized macadamia nut shell powder obtained in step (3) to a particle size of 15-20 μm, to obtain a crude macadamia nut shell natur...

Embodiment 3

[0033] (1) Crush macadamia nut shells to a fine powder that passes through a 20-mesh sieve;

[0034] (2) According to the material-to-liquid ratio L / L, it is 1:10. Soak the fine powder obtained in step (1) with absolute ethanol for 6 hours, soak it repeatedly for 5 times after suction filtration, and dry the filter residue at 80°C for 1 hour. Obtaining defatted macadamia nut shell powder;

[0035] (3) The ratio of material to liquid L / L is calculated as 1:50. Add sodium hypochlorite with a concentration of 60wt% to the defatted macadamia nut shell powder obtained in step (2), and use ultrasonic-assisted extraction to decolorize for 30 minutes, repeat 5 times, and filter , discarding the filtrate, collecting the filter residue and drying at 80° C. for 1 hour to obtain decolorized macadamia nut shell powder;

[0036] (4) Superfinely pulverizing the decolorized macadamia nut shell powder obtained in step (3) to a particle size of 15-20 μm, to obtain a crude macadamia nut shell n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com