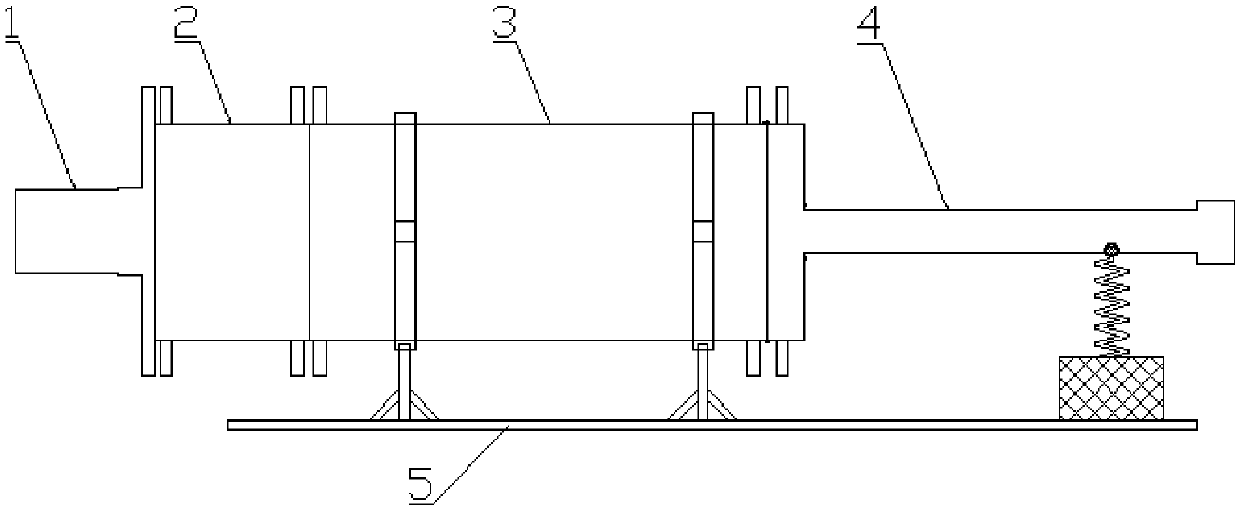

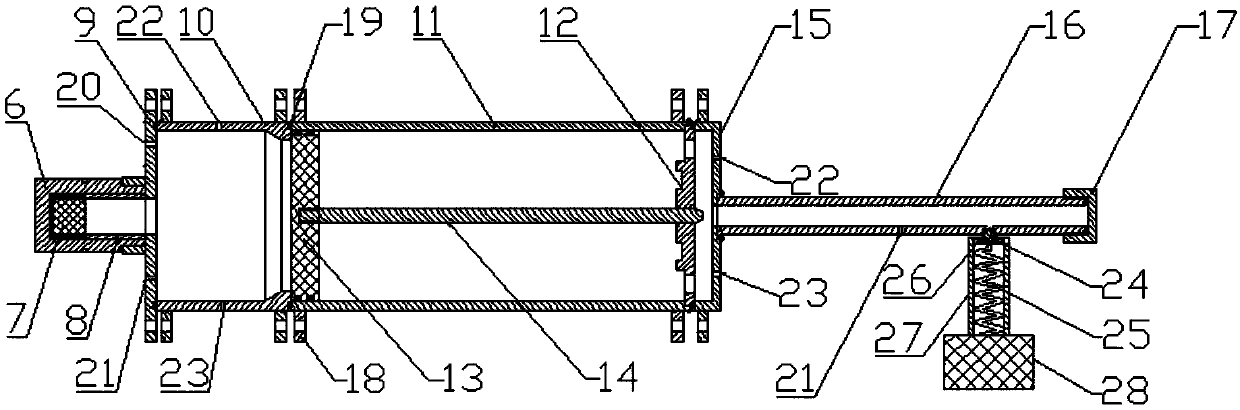

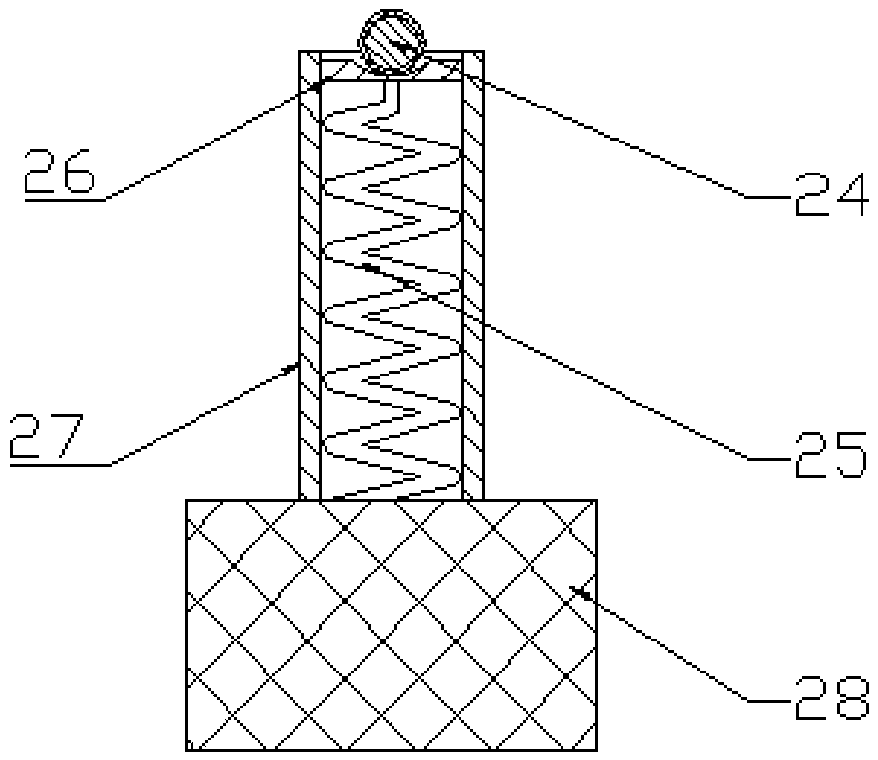

A device for collecting condensed phase combustion products using spring force to control constant pressure

A technology of combustion products and spring force, which is applied in the direction of chemical analysis by combustion, sampling device, etc., can solve the problem that the pressure of the collection container is not stable enough, and achieve the effect of simple structure, easy processing and convenient collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The propellant bracket 6, propellant 7, and propellant bracket 8 are sequentially assembled in the combustion chamber 1, and the propellant combustion end face is 80 mm away from the combustion product collection box body. According to the above-mentioned specific operation steps, the collection of condensed phase combustion products under the condition of flow distance of 80 mm and experimental working pressure of 5 MPa is completed. Using a laser particle size analyzer Mastersizer 2000, Malvern carried out particle size analysis on the collected condensed phase combustion products, and obtained Image 6 The particle size distribution diagram is shown. Under the experimental conditions of a flow distance of 80 mm and a working pressure of 5 MPa, the particle size distribution of the condensed phase combustion products has two obvious peaks, which are the low particle size region of 0.25-1.3 μm and the medium particle size region of 1.3-30 μm. The third section of the c...

Embodiment 2

[0052] In the combustion chamber 1, the propellant bracket 6, the graphite spacer 29, the propellant 7, and the propellant support 8 are sequentially assembled. The graphite spacer pushes the propellant forward by 40 mm, and the combustion end face of the propellant is separated from the combustion product collection box body 40mm. Follow the specific operation steps to complete the collection of condensed phase combustion products under the conditions of a flow distance of 40 mm and an experimental working pressure of 5 MPa. Using a laser particle size analyzer Mastersizer 2000, Malvern carried out particle size analysis on the collected condensed phase combustion products, and obtained Figure 7 The particle size distribution diagram is shown. Under the experimental conditions of a flow distance of 40 mm and a working pressure of 5 MPa, the particle size distribution of the condensed phase combustion product, that is, the 2# sample, has two obvious peaks, which are the low ...

Embodiment 3

[0054] The propellant bracket 6, propellant 7, and propellant support 8 are sequentially assembled in the combustion chamber, and the propellant combustion end face is 80 mm away from the combustion product collection box body. Then, according to the above-mentioned specific operation steps, the collection of condensed phase combustion products under the conditions of a flow distance of 80 mm and an experimental working pressure of 7 MPa is completed. Using a laser particle size analyzer Mastersizer 2000, Malvern carried out particle size analysis on the collected condensed phase combustion products, and obtained Figure 8 The particle size distribution diagram is shown. Under the experimental conditions of a flow distance of 80 mm and a working pressure of 7 MPa, the particle size distribution of the condensed phase combustion product, that is, the 3# sample, has three obvious peaks, which are the low particle size region 0.25-1.3 μm, the medium particle size region 1.3-16 μm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com