Pressure intensity automatically balanced condensed-phase combustion product pollution-free collecting device

An automatic balance and combustion product technology, applied in the preparation of test samples, etc., can solve the problems of inability to collect condensed phase combustion products, affect the accuracy of experimental results, and unrepresentative samples, etc., and achieve simple structure, easy processing, and no The effect of pollution collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] specific implementation plan

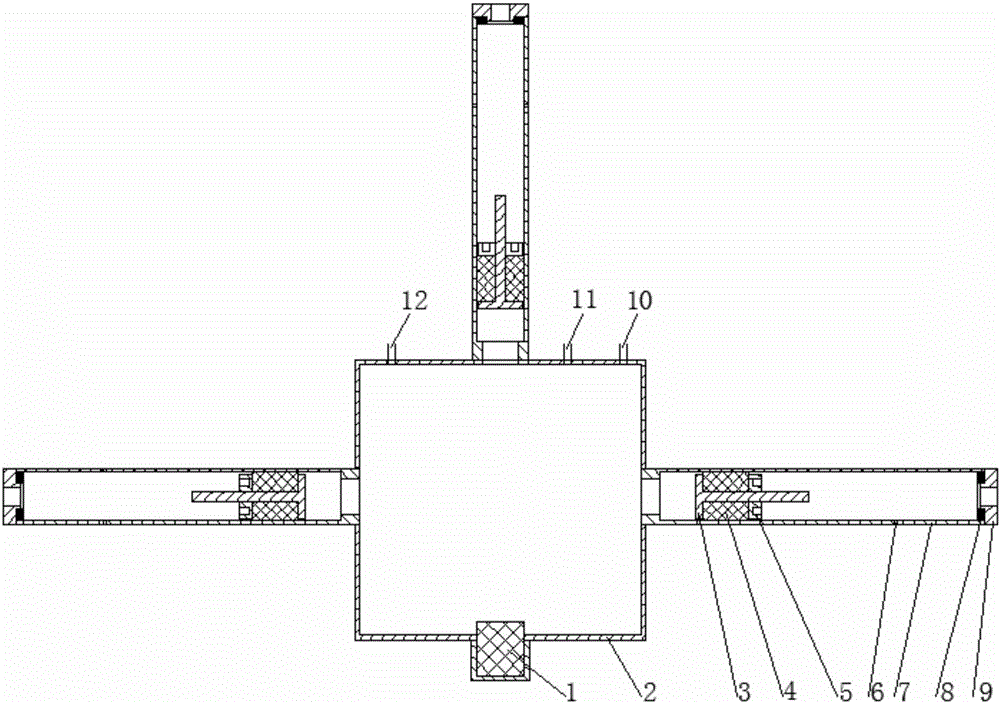

[0025] This embodiment is a non-polluting collection device for the pressure automatic balance condensed phase combustion product.

[0026] In this embodiment, the pressure automatic balance condensed phase combustion product pollution-free collection device uses volume self-adjusting parts to change the volume size, and then builds a pressure negative feedback mechanism to maintain the stability of the pressure in the combustion chamber of the engine.

[0027] The principle of volume self-regulation of the collection device is:

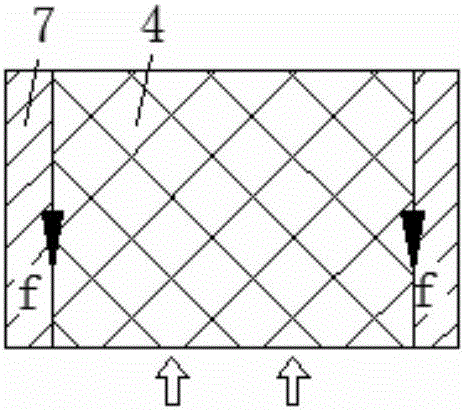

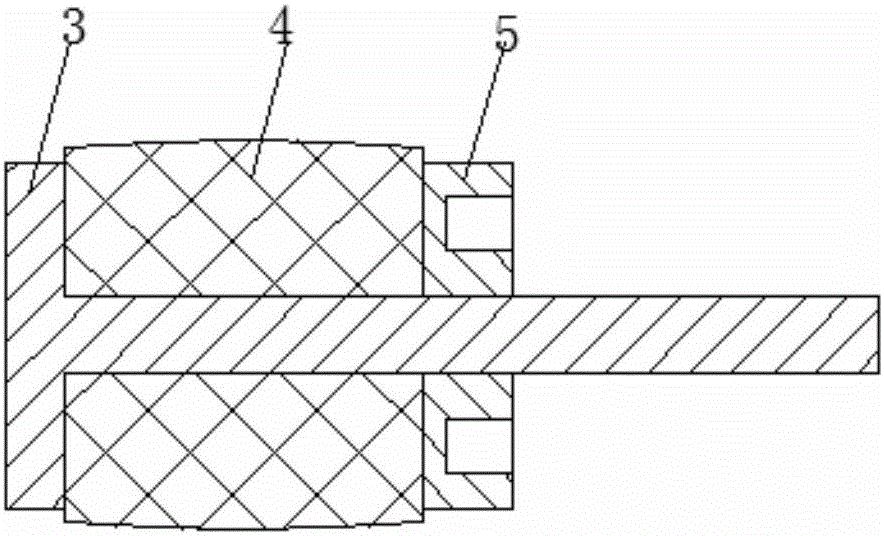

[0028] During the propellant combustion process, the pressure difference P inside and outside the combustion chamber makes the end surface of the cylinder connected to it produce a pressure F, F=PA, where F is the pressure, P is the pressure difference, and A is the end surface area. Since the pre-tightening stud and the pre-tightening nut in the cylinder generate radial pressure N on the silicone rubber ring, u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com