Heat regenerator of Stirling cryocooler and processing method of packing bodies for heat regenerator

A technology of regenerators and refrigerators, which is applied in the direction of refrigerators, superheaters, refrigeration components, etc., can solve the problems of inconvenient cleaning or replacement, cumbersome removal operations, and low heat exchange efficiency, so as to improve the speed of disassembly and assembly, Large heat transfer surface area, the effect of improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

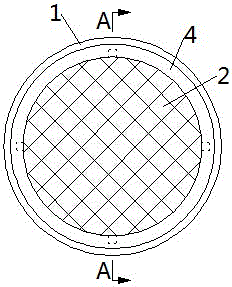

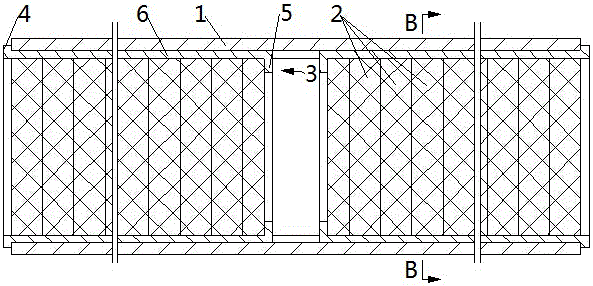

[0029] Such as Figure 1-7 The regenerator of the Stirling refrigerator shown includes a cylinder body 1 and a packing body 2 filled in the cylinder body 1; frame 3; the mounting frame 3 includes a first ring plate 4 located at the end of the cylinder body 1, a second ring plate 5 located inside the cylinder body 1 and the outer edge of which is attached to the inner wall of the cylinder body 1, and four connecting the first ring plate 5 4 end faces of a ring plate and the guide bar 6 on the outer edge of the second ring plate 5, along the circumferential direction of the first ring plate 4; the inner diameter of the first ring plate 4 is equal to the outer diameter of the second ring plate 5 diameter, its outer diameter is greater than the inner diameter of the cylinder 1; the inward wall of the guide bar 6 is flush with the inner wall of the cylinder 1; the inner wall of the cylinder 1 is evenly distributed with four guide grooves 7 that are slidably matched with the guide b...

Embodiment 2

[0034] A method for processing a packing body used in a regenerator, comprising the following steps:

[0035] (1) Cloth, superimpose the selected pieces of stainless steel wire mesh to the required thickness, or evenly spread the messy stainless steel wire (extremely fine stainless steel wire) to the required thickness, and then compact it with tooling, the given The pressure is 400N, and the specific pressure is determined according to the porosity of the required sintered mesh or sintered felt;

[0036] (2) Put the compacted stainless steel wire mesh or evenly stacked stainless steel wire into a high-temperature vacuum furnace, heat up to 1250°C, and keep it at this temperature for 3 hours to obtain a sintered stainless steel wire mesh or stainless steel felt blank;

[0037] (3) Pass the protective gas into the high-temperature vacuum furnace to cool the sintered billet to room temperature;

[0038] (4) Machining the cooled sintered billet to the required shape and size to ...

Embodiment 3

[0040] A method for processing a packing body used in a regenerator, comprising the following steps:

[0041] (1) Cloth, superimpose the selected pieces of stainless steel wire mesh to the required thickness, or evenly spread the messy stainless steel wire (extremely fine stainless steel wire) to the required thickness, and then compact it with tooling, the given The pressure is 600N, and the specific pressure is determined according to the porosity of the required sintered mesh or sintered felt;

[0042] (2) Put the compacted stainless steel wire mesh or evenly stacked stainless steel wire into a high-temperature vacuum furnace, heat up to 1400°C, and keep it at this temperature for 2 hours to obtain a sintered stainless steel wire mesh or stainless steel felt blank;

[0043] (3) Pass the protective gas into the high-temperature vacuum furnace to cool the sintered billet to room temperature;

[0044] (4) Machining the cooled sintered billet to the required shape and size to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com