Construction method for folding type structural slab post-cast strip joint formwork

A construction method and technology of post-casting belts, which are applied in the direction of formwork/formwork/work frame, building structure, and on-site preparation of building components, which can solve the complex installation and dismantling process, affect the construction period, and cumbersome construction process and other problems, to achieve the effect of simple support and dismantling, simple processing and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

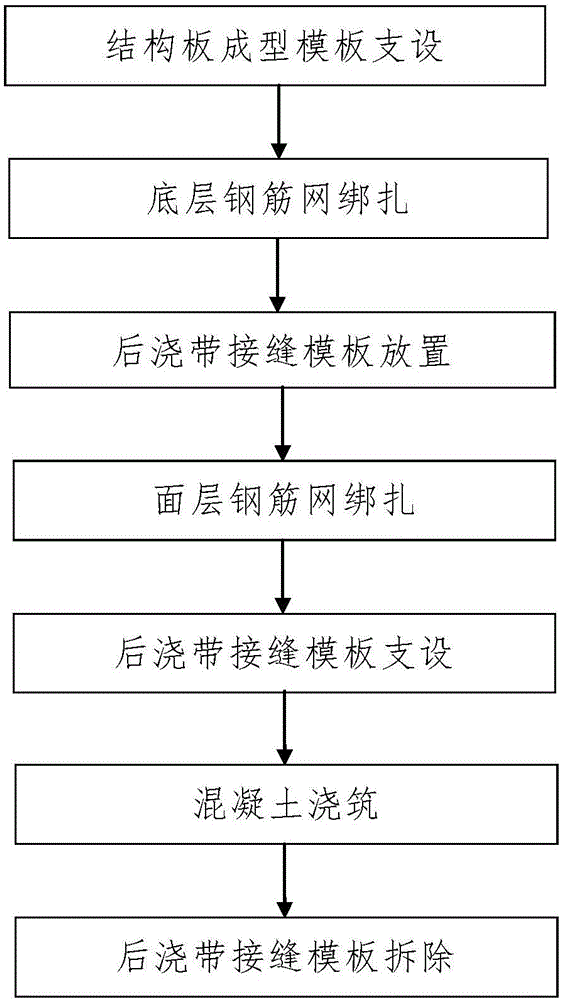

[0057] Such as figure 1 The construction method of a folded structural slab post-casting joint formwork shown includes the following steps:

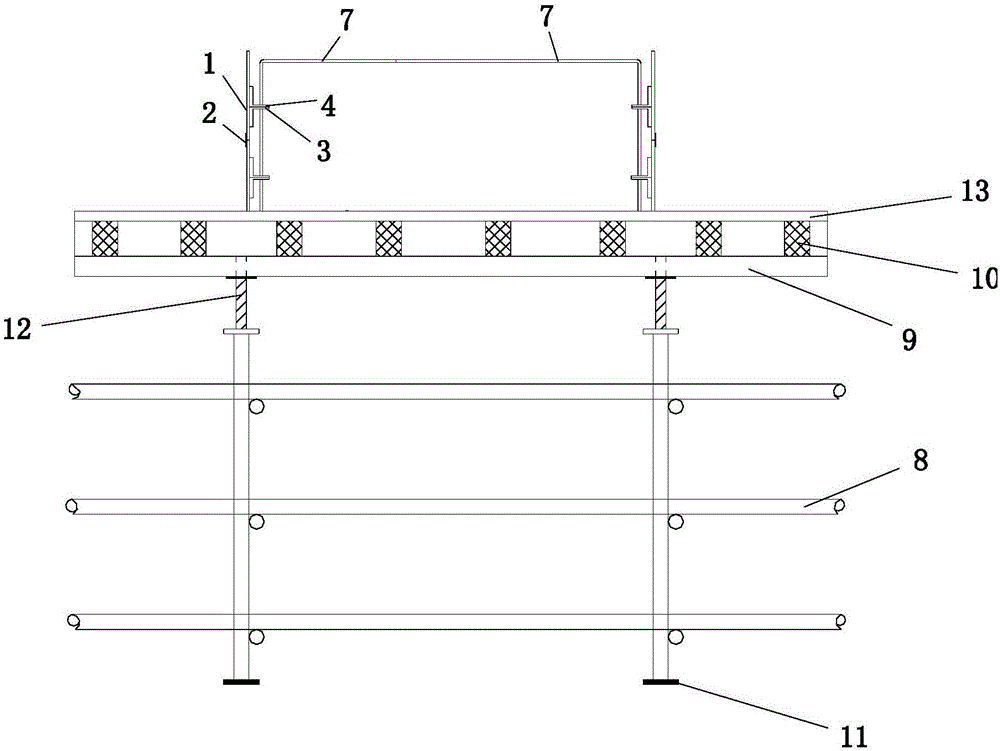

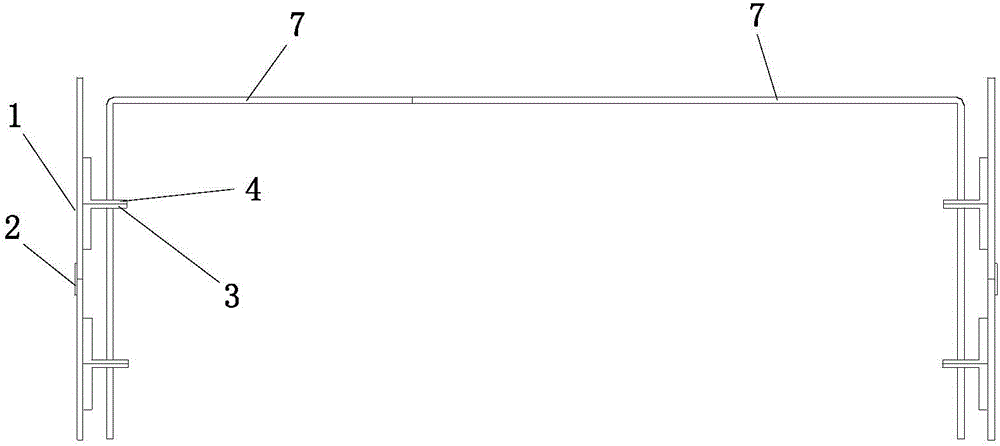

[0058] Step 1. Supporting of the forming formwork of the structural slab: supporting the forming formwork of the constructed structural slab; the forming formwork includes a bottom formwork 13 supported under the constructed structural slab and a side formwork arranged on the bottom formwork 13 The constructed structural slab is a cast-in-place reinforced concrete slab that is laid horizontally, and the bottom template 13 is laid horizontally, see figure 2 ;

[0059] The cast-in-place reinforced concrete slab is provided with a bottom reinforcement mesh and a surface layer reinforcement mesh above the bottom reinforcement mesh, the bottom reinforcement mesh and the surface layer reinforcement mesh are arranged horizontally and both are formed by The vertical horizontal steel bars are bound with multiple horizontal horizontal steel bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com