Preparation method of sponge structure iron/SiC particle-based oil-water separation enhancement layer material

An oil-water separation and structural technology, which is applied in the field of preparation of sponge structure iron/SiC particle-based oil-water separation enhancement layer materials, can solve problems such as secondary environmental pollution, and achieve strong adsorption, strong drainage, and oil-water separation efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

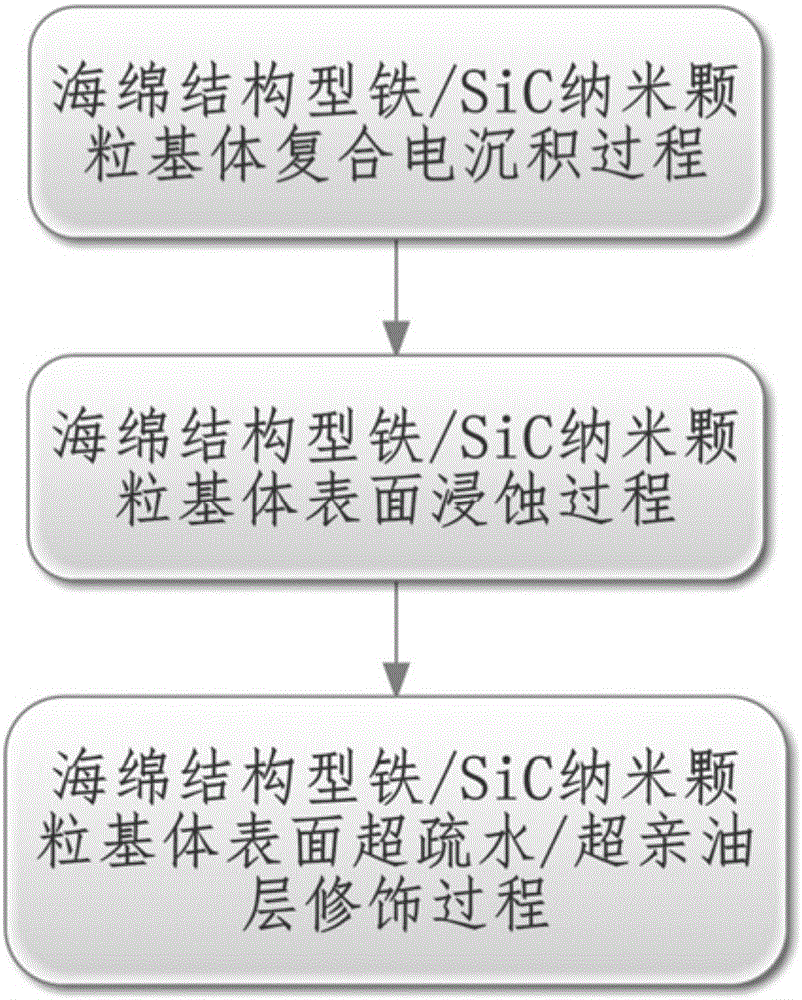

[0032] Preferred Embodiment 1 of the present invention provides a method for preparing a sponge-structured iron / SiC nanoparticle composite material, comprising the following steps in order:

[0033] ① Conductive treatment of polyurethane sponge model: Mix nano-carbon powder, nano-iron powder, ethyl hydroxyethyl cellulose, xanthan gum, sodium silicate and deionized water to form a conductive paste. The mass percentages of each component in the above-mentioned conductive paste are respectively: nano-carbon powder 18%, nano-iron powder 20%, ethyl hydroxyethyl cellulose 3%, xanthan gum 5%, ammonium bicarbonate 1.5%, and the rest are Deionized water; After fully soaking the polyurethane sponge in the conductive paste, dry it in a 35°C drying oven for 4 hours to obtain a conductive polyurethane sponge model.

[0034] ② Sponge structure type iron / SiC nanoparticle matrix composite electrodeposition treatment: the concentration is analytically pure iron oxide, hydrochloric acid with a ...

Embodiment 2

[0038] Preferred embodiment 2 of the present invention provides a method for preparing a sponge-structured iron / SiC nanoparticle composite material with reduced surface energy, comprising the following steps in order:

[0039] ① Conductive treatment of polyurethane sponge model: Mix nano-carbon powder, nano-iron powder, ethyl hydroxyethyl cellulose, xanthan gum, sodium silicate and deionized water to form a conductive paste. The mass percentages of each component in the above-mentioned conductive paste are respectively: nano-carbon powder 18%, nano-iron powder 20%, ethyl hydroxyethyl cellulose 3%, xanthan gum 5%, ammonium bicarbonate 1.5%, and the rest are Deionized water; After fully soaking the polyurethane sponge in the conductive paste, dry it in a 35°C drying oven for 4 hours to obtain a conductive polyurethane sponge model.

[0040] ② Sponge structure type iron / SiC nanoparticle matrix composite electrodeposition treatment: the concentration is analytically pure iron oxid...

Embodiment 3

[0045] Preferred embodiment 3 of the present invention provides a preparation method of a sponge-structured iron / SiC nanoparticle-based superhydrophobic / superoleophilic reinforcement layer oil-water separation material, comprising the following steps in order:

[0046] ① Conductive treatment of polyurethane sponge model: Mix nano-carbon powder, nano-iron powder, ethyl hydroxyethyl cellulose, xanthan gum, sodium silicate and deionized water to form a conductive paste. The mass percentages of each component in the above-mentioned conductive paste are respectively: nano-carbon powder 18%, nano-iron powder 20%, ethyl hydroxyethyl cellulose 3%, xanthan gum 5%, ammonium bicarbonate 1.5%, and the rest are Deionized water; After fully soaking the polyurethane sponge in the conductive paste, dry it in a 35°C drying oven for 4 hours to obtain a conductive polyurethane sponge model.

[0047] ② Sponge structure type iron / SiC nanoparticle matrix composite electrodeposition treatment: the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com