Method for electrolytically preparing bright nickel in alkaline electrolyte

An electrolyte and bright nickel technology, applied in the field of non-ferrous metallurgy, can solve the problems of nickel blackening and brittleness, achieve good toughness, simple process flow, and meet industrial needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

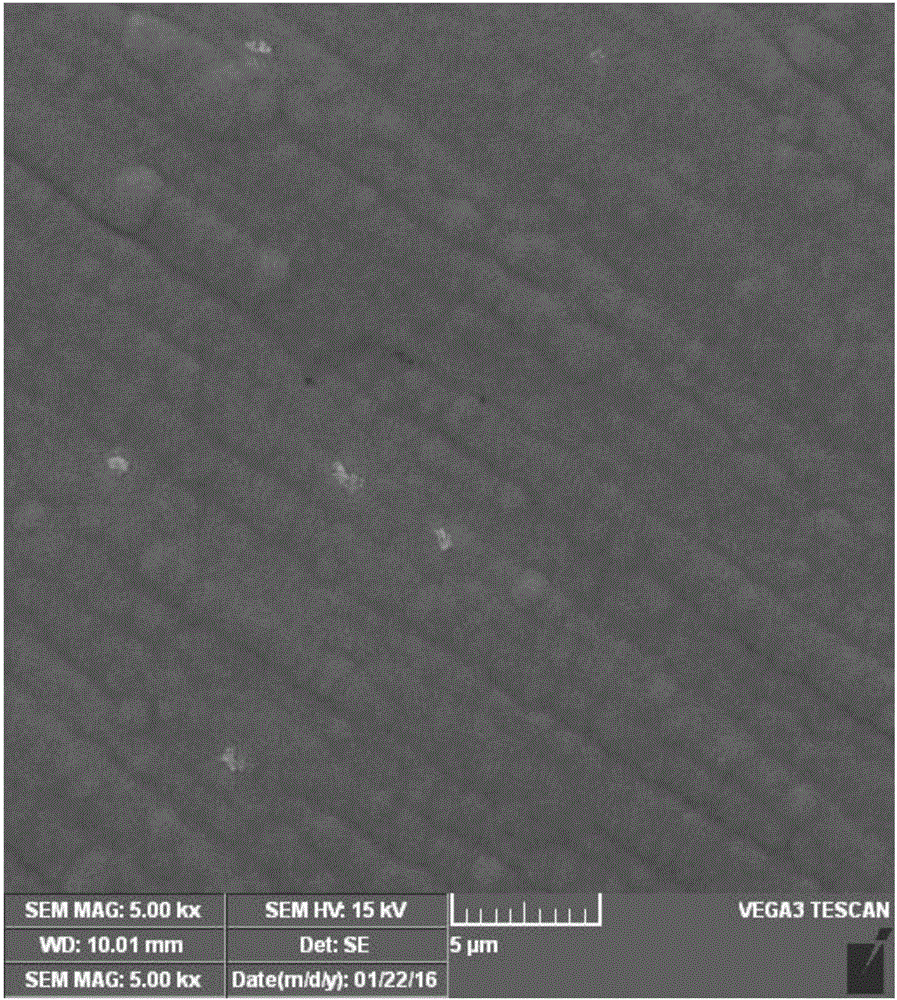

Image

Examples

Embodiment 1

[0037] Configure the anode chamber electrolyte containing 30g / L of ammonium chloride. Take the high-matte nickel electrode as the anode, soak it in 1mol / L nitric acid for 50 minutes to remove the surface oxide layer and impurities, take it out, rinse it with deionized water, and dry it with cold wind. Using stainless steel as the cathode material, after grinding with 1#, 3#, and 5# sandpaper, degreasing with absolute ethanol, washing with deionized water and drying with cold air, put the cathode and anode into the cathode and anode chambers of the electrolytic cell at the same time. Pour the electrolytic solution containing 20g / L nickel chloride, 30g / L ammonium chloride, 25g / L ammonia water, and 0.02g / L sodium benzenesulfinate into the chamber, control the electrodeposition temperature to 20°C, and the current density to -50A / m 2 , Stir the electrolyte at a speed of 700r / min. After 1 hour of electrodeposition, take out the cathode, rinse the residual electrolyte on the surfa...

Embodiment 2

[0041] Configure the anode compartment electrolyte containing 300g / L of ammonium chloride. Take the high-matte nickel electrode as the anode, soak it in 5mol / L nitric acid for 15min to remove the surface oxide layer and impurities, take it out, rinse it with deionized water, and dry it with cold wind. Using stainless steel as the cathode material, after grinding with 1#, 3#, 5# sandpaper, degreasing with absolute ethanol, washing with deionized water and drying with cold air, put the cathode and anode into the cathode and anode of the electrolytic cell at the same time, and pour the cathode chamber into Electrolyte containing 400g / L of nickel chloride, 300g / L of ammonium chloride, 250g / L of ammonia water, and 1.5g / L of sodium benzenesulfinate, controlled electrodeposition temperature to 70°C, and current density to -400A / m 2 , Stir the electrolyte at a speed of 300r / min. After 50 hours of electrodeposition, take out the cathode, rinse the residual electrolyte on the surface wi...

Embodiment 3

[0045] Configure the anode compartment electrolyte containing 50g / L of ammonium chloride. Take the high-matte nickel electrode as the anode, soak it in 2mol / L nitric acid for 35min to remove the surface oxide layer and impurities, take it out, rinse it with deionized water, and dry it with cold wind. Using stainless steel as the cathode material, after grinding with 1#, 3#, 5# sandpaper, degreasing with absolute ethanol, washing with deionized water and drying with cold air, put the cathode and anode into the cathode and anode of the electrolytic cell at the same time, and pour the cathode chamber into Electrolyte containing 100g / L of nickel chloride, 80g / L of ammonium chloride, 60g / L of ammonia water, and 0.05g / L of sodium benzenesulfinate. Control the electrodeposition temperature at 40°C and the current density at -100A / m 2 , Stir the electrolyte at a speed of 400r / min. After 1 hour of electrodeposition, take out the cathode, rinse the residual electrolyte on the surface wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com