Production method and apparatus of polyvinyl alcohol

A polyvinyl alcohol and production method technology, applied in the field of polyvinyl alcohol production devices, can solve the problems of reducing market competitiveness, reducing product quality, increasing production costs, etc., and achieving enhanced market competitiveness, convenient operation, and increased time and area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

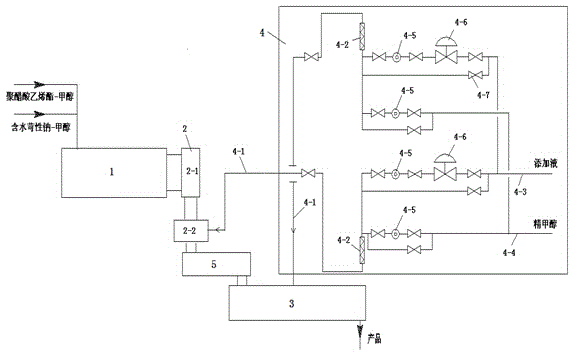

[0030] Example 1, the production method of polyvinyl alcohol (PVA 18-99), the production device see figure 1, including alcoholysis machine 1, pulverizer 2 and dryer 3, pulverizer 2 includes first pulverizer 2-1 and second pulverizer 2-2 and is connected, first pulverizer 2-1 is connected with alcoholysis machine 1 , the second pulverizer 2-2 is connected with the dryer 3, and the second pulverizer 2-2 is connected with the substituent delivery system 4; The machine 2-2 is connected with the dryer 3; one way of the substitute agent input pipeline 4-1 is connected with the refined methanol delivery pipeline 4-3 and the additive liquid delivery pipeline 4-4 through a pipeline mixer 4-2, and the other way of the substitute agent input pipeline is 4-1 is connected with refined methanol delivery pipeline 4-3 and additive liquid delivery pipeline 4-4 through another pipeline mixer 4-2. The refined methanol delivery pipeline 4-4 is provided with a flowmeter 4-5 and a control valve 4...

Embodiment 2

[0037] Example 2, the production method of polyvinyl alcohol PVA24-97, the production device is as in Example 1, including the following steps: after adjusting the polyvinyl acetate-methanol solution with a mass concentration of 30% to a specified temperature of 40-50 ° C, enter the mixing machine, the caustic soda-methanol solution with a water content of 20% also enters the mixer, and the two materials are fully mixed in the mixer and then enter the alcoholysis machine 1 for alcoholysis reaction. During the mixing process, the water in the caustic soda-methanol solution be evenly distributed inside the material. The uniformly mixed material reacts while being conveyed in the belt type alcoholysis machine. The material changes from liquid to solid, and then enters the first pulverizer 2-1 to be pulverized into strip-shaped materials, and the strip-shaped materials enter the second pulverizer 2-2 to be crushed. Grinding into granular materials, one-third of the methyl acetate-...

Embodiment 3

[0044] Embodiment 3, polyvinyl alcohol ( PVA 088-04) production method, production equipment see figure 1 , including the following steps: after adjusting the polyvinyl acetate-methanol solution with a mass concentration of 40% to a temperature of 40-50°C, adding it to a mixer, and adding a caustic soda-methanol solution with a water content of 10% to the mixer at a rate of 100 ~400 l / h, after being fully mixed, enter the alcoholysis machine 1 for alcoholysis reaction. During the mixing process, the water in the caustic soda-methanol solution is evenly distributed inside the material; the uniformly mixed material is in the alcoholysis machine 1. Reacting while conveying, the material changes from liquid to solid, and then enters the pulverizer 2 to be pulverized into specified particles. The material first enters the first pulverizer 2-1 to be pulverized into strip materials, and then enters the second pulverizer 2-2 to be pulverized into granular materials. One-third of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com