Sagger for lithium battery cathode material and preparation method thereof

A technology for positive electrode materials and lithium batteries, which is applied in the field of saggers for lithium battery positive electrode materials and its preparation, can solve the problems of poor corrosion resistance of saggers, easy pollution of battery raw materials, poor thermal shock stability, etc., and achieve saggers Effect of long life, reduction of corrosion channels, and improvement of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

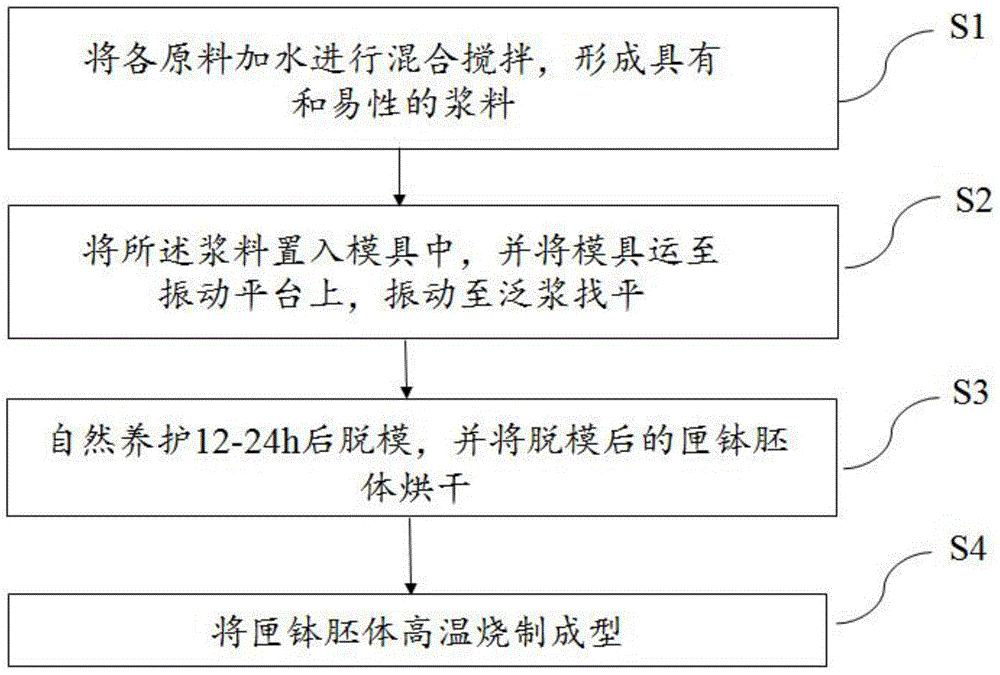

Method used

Image

Examples

Embodiment 1

[0036] The invention provides a sagger for positive electrode materials of lithium batteries, which is composed of the following components in weight percentage: 55% of platy corundum, 18.5% of cordierite, 8.3% of aluminum titanate, 10% of pure calcium aluminate cement, α-oxidized Aluminum powder 8%, sodium tripolyphosphate 0.15% and explosion-proof fiber 0.05%.

[0037] The platy corundum includes large-grain tabular alumina and small-grain tabular alumina, the grain size range of the large-grain tabular alumina is 0.2-1mm, and the weight percentage is 40%, and the grain size range of the small-grain tabular alumina is ≤0.088mm, the weight percentage is 15%.

[0038] The cordierite includes cordierite with large particle size and cordierite with small particle size, the particle size range of the large particle size cordierite is 0-0.2mm, and the weight percentage is 10%, and the particle size range of the small particle size cordierite is ≤0.088mm, The weight percentage is ...

Embodiment 2

[0060] The invention provides a sagger for positive electrode materials of lithium batteries, which is composed of the following components in weight percent: 40.3% of platy corundum, 33.1% of cordierite, 15% of aluminum titanate, 5.2% of pure calcium aluminate cement, α-oxidized Aluminum powder 6.12%, sodium tripolyphosphate 0.2% and explosion-proof fiber 0.08%.

[0061] The platy corundum includes large-grain tabular alumina and small-grain tabular alumina, the grain size range of the large-grain tabular alumina is 1-1.5mm, and the weight percentage is 20%, and the grain size range of the small-grain tabular alumina is ≤0.088mm, the weight percentage is 20.3%.

[0062] The cordierite includes cordierite with large particle size and cordierite with small particle size, the particle size range of the large particle size cordierite is 0.2-0.5mm, and the weight percentage is 20%, and the particle size range of the small particle size cordierite is ≤0.088mm, The weight percentag...

Embodiment 3

[0073] The invention provides a sagger for positive electrode materials of lithium batteries, which is composed of the following components in weight percentage: 20% of platy corundum, 44.3% of cordierite, 9.3% of aluminum titanate, 20% of pure calcium aluminate cement, α-oxidized Aluminum powder 6%, sodium tripolyphosphate 0.3% and explosion-proof fiber 0.1%.

[0074] The platy corundum includes large-grain tabular alumina and small-grain tabular alumina, the grain size range of the large-grain tabular alumina is 1.5-2.3mm, and the weight percentage is 10%, and the grain size range of the small-grain tabular alumina is ≤0.088mm, the weight percentage is 10%.

[0075] The cordierite includes cordierite with large particle size and cordierite with small particle size, the particle size range of the large particle size cordierite is 0.5-0.8mm, and the weight percentage is 30%, the particle size range of the small particle size cordierite is ≤0.088mm, The weight percentage is 14...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com