Novel graphitization method of lithium ion battery graphite negative electrode material

A lithium-ion battery and graphite negative electrode technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve problems such as increased quality control risks, inability to comprehensively utilize, increase outsourcing freight costs, etc., and achieve high density and volume density Increase, heat preservation effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

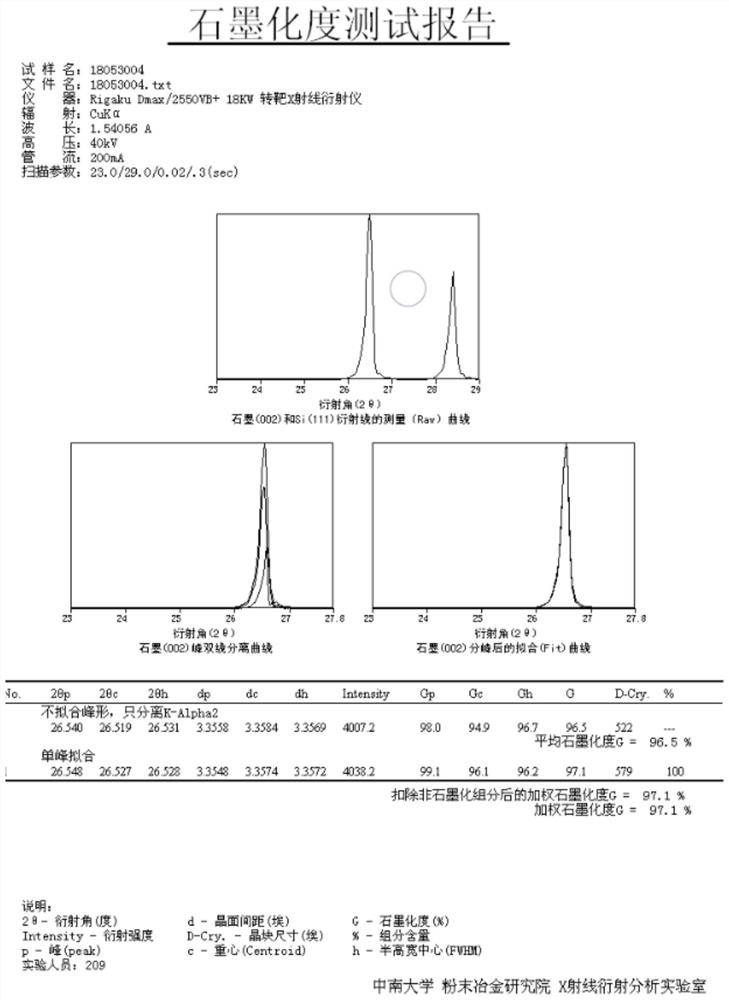

Examples

Embodiment 1

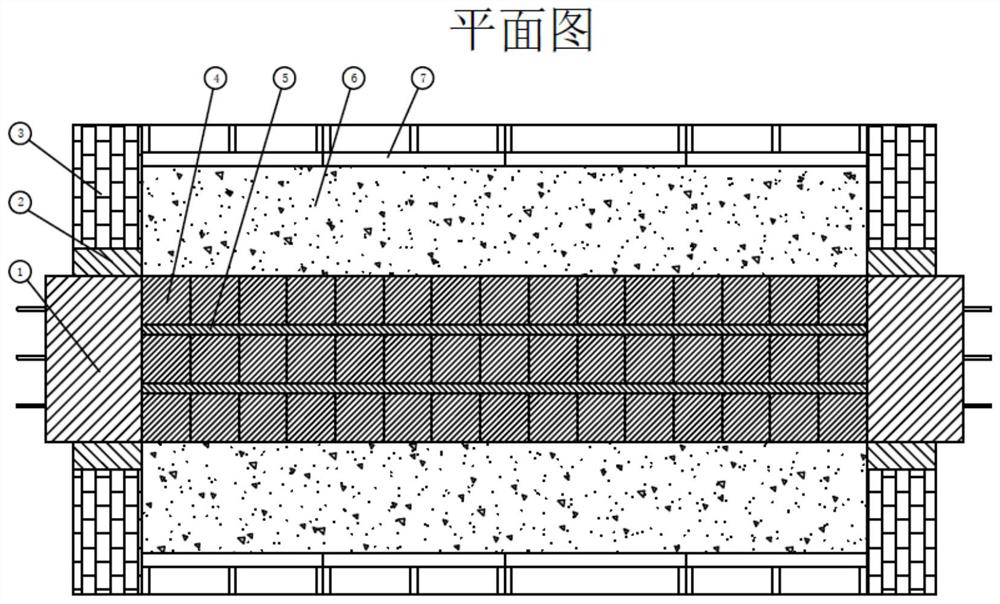

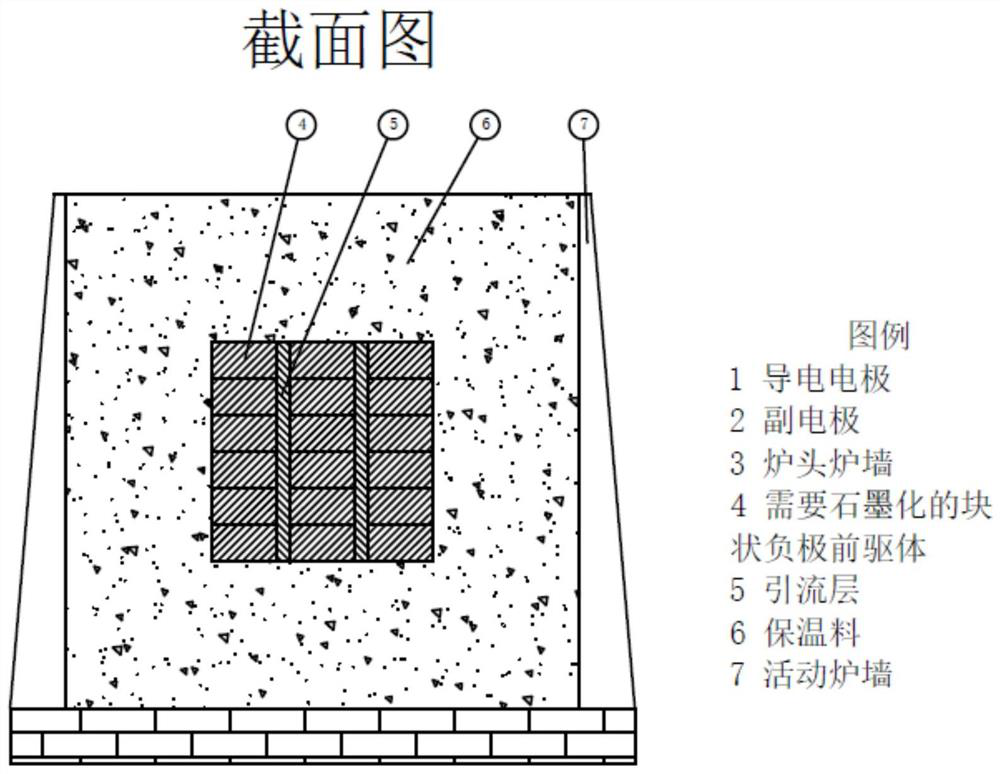

[0058] This embodiment is a new graphitization method with energy saving, low carbon, high efficiency and low cost for graphite negative electrode material of lithium ion battery, which specifically includes the following steps:

[0059] (1) Preparation of graphite negative electrode block requiring graphitization (making graphite negative electrode precursor into block precursor):

[0060] Mix 30 tons of graphite cathode precursor to be graphitized with 3 tons of asphalt (softening point 90 ~ 94 ℃, residual carbon 55%);

[0061] The mixed materials are molded with a molding machine. The molding shape is a cuboid and the molding size is 350mm * 350mm * 150mm.

[0062] Mark the model and batch on the upper right corner of each surface of the block with a code printer. The model and batch used this time is sc331ah1101.

[0063] (2) Design charging mode:

[0064] The situation of silicon carbide smelting furnace in the implementation process is described as follows:

[0065] Transforme...

Embodiment 2

[0093] This embodiment is a new graphitization method with energy saving, low carbon, high efficiency and low cost for graphite negative electrode material of lithium ion battery, which specifically includes the following steps:

[0094] (1) Preparation of graphite negative electrode block requiring graphitization:

[0095] 30 tons of graphitized graphite negative electrode precursor shall be kneaded with 3 tons of asphalt (softening point 90-94 ℃, residual carbon 55%);

[0096] The kneaded material is extruded by extrusion molding equipment. The molding shape is a cylinder and the size of the molding block is φ 600mm*1000mm。

[0097] Mark the model and batch on the upper right corner of each surface of the block with a code printer. The model and batch used this time is sc331ah1106.

[0098] (2) Design charging mode:

[0099] The situation of silicon carbide smelting furnace in the implementation process is described as follows:

[0100] Transformer: 8000kVA

[0101] Maximum curr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com