Low-scattering covering for external field testing and preparation method thereof

An external field testing, low-scattering technology, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of not considering the delamination of the adhesive layer, only considering the reflectivity of the material, loss of electromagnetic waves, etc. Good site layout quickly, achieve designability, and ensure the effect of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

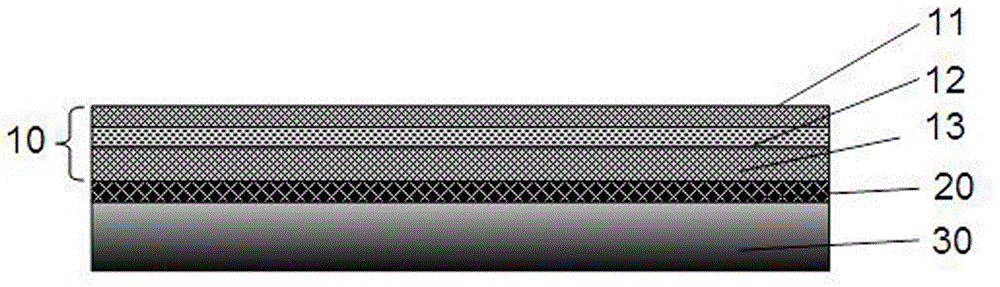

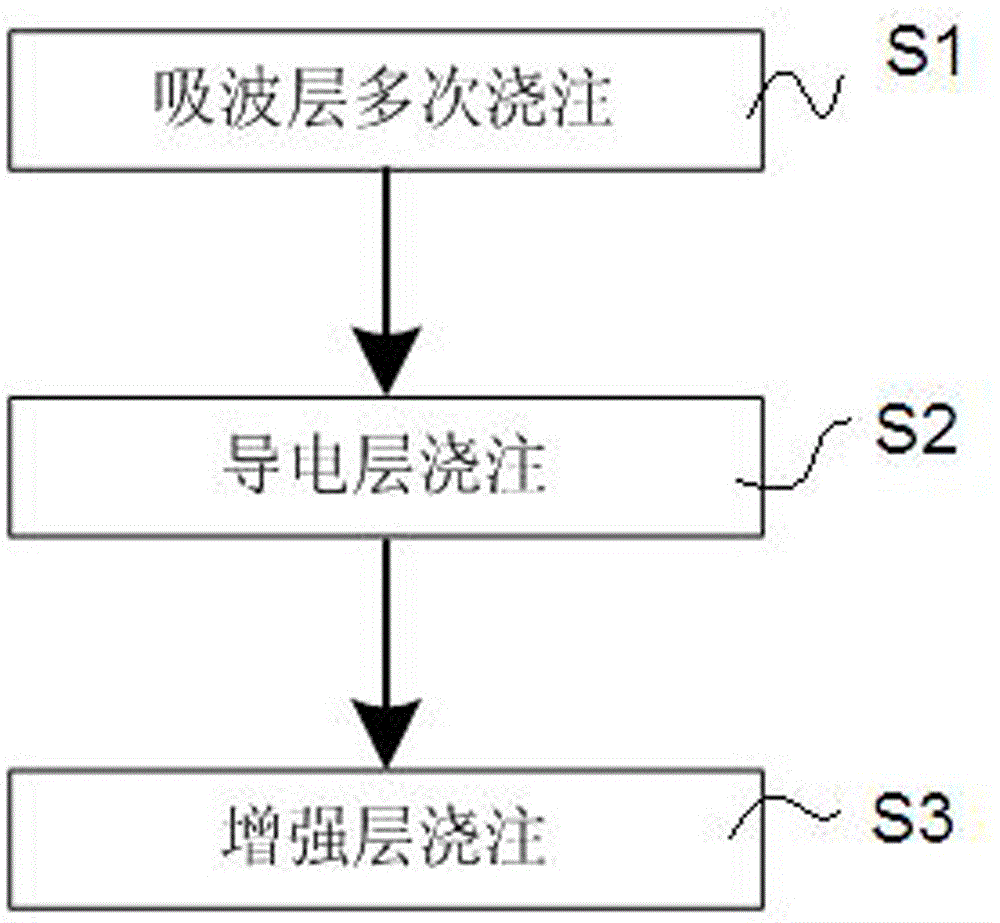

[0043] The preparation method of the low-scattering covering for field testing provided by the invention comprises the following steps, such as figure 2 Shown:

[0044] Step 1 (S1): Multi-layer absorbing material casting process to prepare the absorbing layer

[0045] Spherical or sheet-shaped carbonyl iron particles and rubber are filled at a volume addition ratio of 5-50%. The bottom absorbing layer is a mixture of sheet-shaped carbonyl iron and room temperature curing silicone rubber materials. Coupling agent (such as silane coupling agent KH550, KH560, etc.) with iron powder mass ratio of 1-2%, until mixed evenly, then add curing agent for room temperature curing silicone rubber filler (such as epoxy silane crosslinking agent), mass The ratio is 5% of the rubber. After adding the curing agent and mixing evenly, pour it into the predetermined plane cavity. When the rubber material reaches the semi-cured state, configure the second layer of material, the additive is spher...

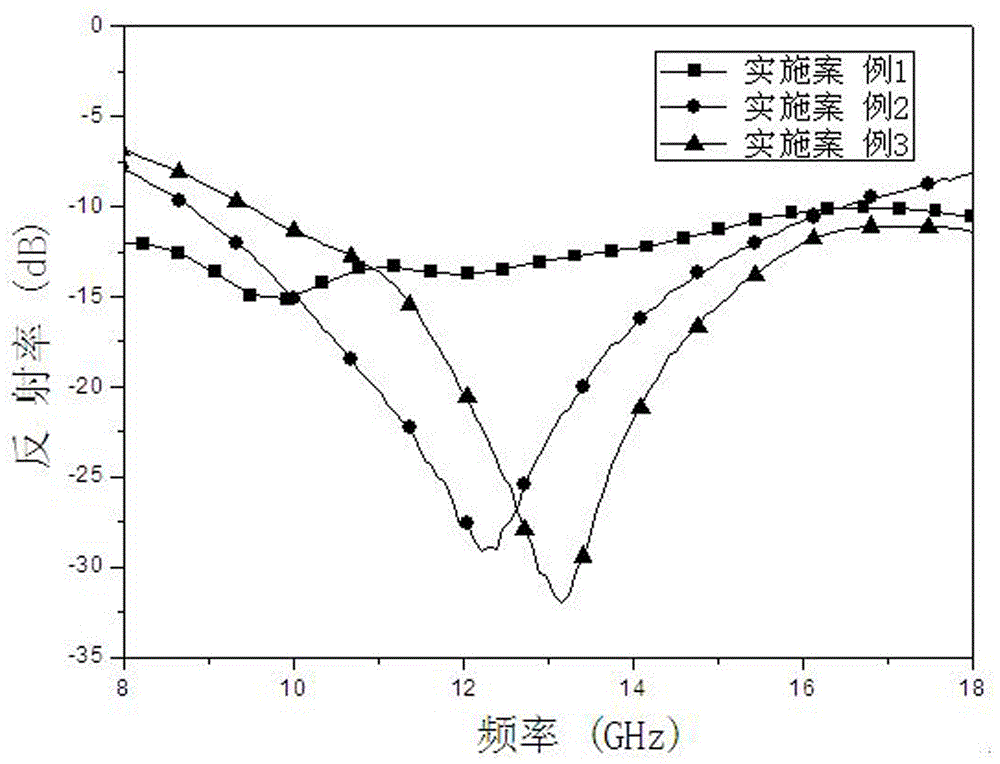

Embodiment 1

[0053] ① The first layer of absorbing material is a mixture of spherical carbonyl iron with a volume addition ratio of 20% and room temperature curing silicone rubber material, and the thickness of the planar cavity is set to 0.43mm;

[0054] ②For the second layer of absorbing material, the additive is sheet-shaped carbonyl iron particles, the volume addition ratio is 20%, and the thickness of the planar cavity is set to 0.77mm;

[0055] ③For the third layer of absorbing material, the additive is sheet-shaped carbonyl iron particles, the volume addition ratio is 45%, and the thickness of the planar cavity is set to 0.4mm;

[0056] ④ For the fibers in the middle conductive layer, the average length is 3 mm, the average diameter is 20 μm, the average length-to-diameter ratio is 150, the volume ratio is 30%, and the thickness of the prepared material is 2 mm.

[0057] ⑤ For the bottom reinforcement layer, the thickness of both layers of rubber is 1mm, the mesh size of the mesh cl...

Embodiment 2

[0059] ① The first wave-absorbing layer is a mixture of sheet-shaped carbonyl iron with a volume addition ratio of 10% and room temperature curing silicone rubber material, and the thickness of the planar cavity is set to 1.5mm;

[0060] ②For the second layer of absorbing material, the additive is spherical carbonyl iron particles, the volume addition ratio is 15%, and the thickness of the planar cavity is set to 0.5mm;

[0061] ③For the fibers in the middle conductive layer, select the average length of 2mm, the average diameter of 20μm, the average aspect ratio of 100, the addition ratio is 40% by volume, and the thickness of the prepared material is 2mm.

[0062] ④ For the bottom reinforcement layer, the thickness of both layers of rubber is 1.5mm, the mesh size of the mesh cloth laid in the middle is 15mm, and the fiber is glass fiber mesh cloth. Example 3:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com