A kind of multi-material composite 3D printer and its working method and application

A 3D printer and working method technology, applied in the field of additive manufacturing, can solve the problems of low printing resolution, low mixing efficiency, and difficulty in printing multiple materials, achieve a wide range of printing materials, solve low circuit resolution, and print droplets. Small diameter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

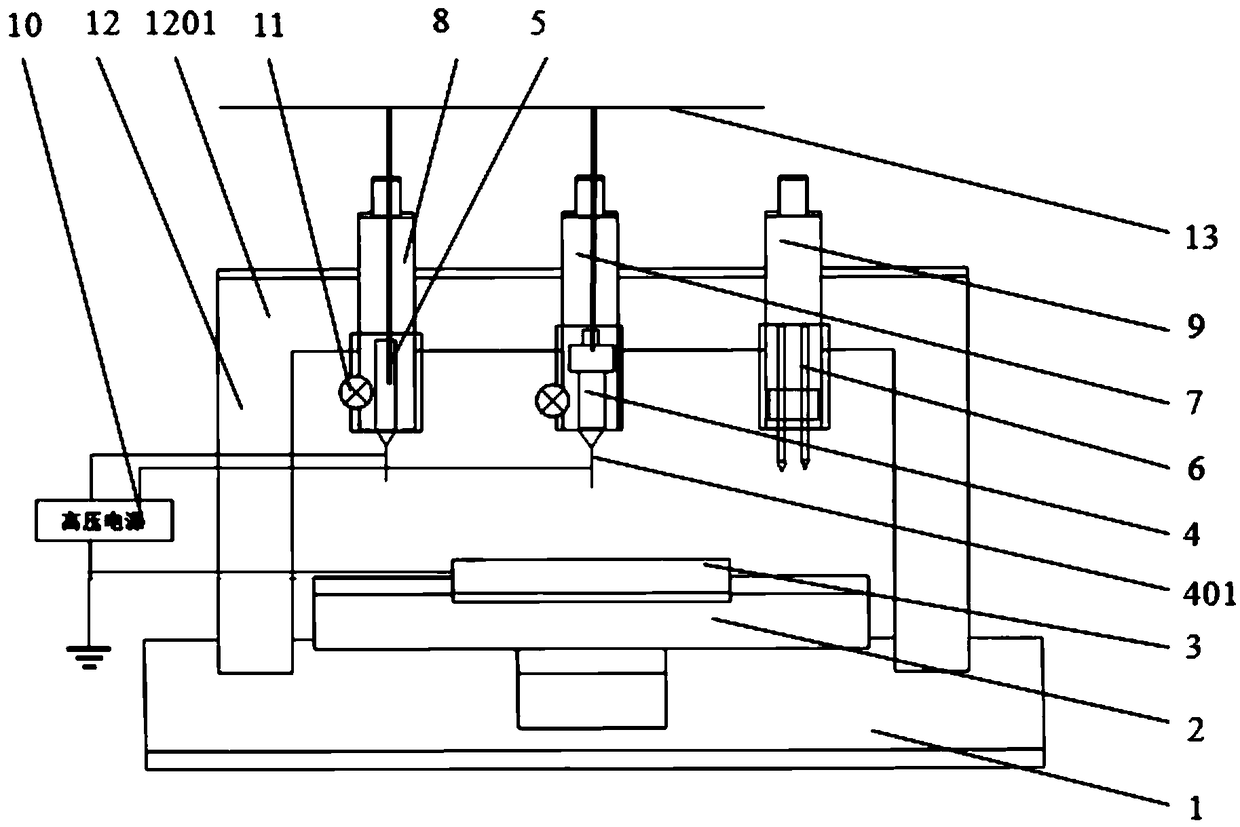

[0055] like figure 1 As shown, the multi-material composite 3D printer includes: base 1, x-y workbench 2, print bed 3, first nozzle 4, second nozzle 5, third nozzle 6, z-direction worktable 1 7, z-direction workbench II 8, z direction workbench III 9, high voltage power supply 10, UV curing light source 11, frame 12, pressure pipeline 13. The base 1 is placed at the bottom; the x-y workbench 2 is placed on the base 1; the printing bed 3 is fixed on the x-y workbench 2; the first nozzle 4 is placed directly above the print bed 3 and is in phase with the z-direction workbench I 7 Connection; the z-direction workbench I 7 is fixed on the beam 1201 of the frame 12; the second nozzle 5 is placed above the printing bed 3 and connected with the z-direction workbench II 8; the z-direction workbench II 8 is fixed on the frame 12 on the beam 1201; the third nozzle 6 is placed above the print bed 3 and connected with the z-direction workbench III 9; the z-direction workbench III 9 is fi...

Embodiment 2

[0069] The working method of multi-material composite 3D printer comprises the following steps:

[0070] Step 1: Utilize the first shower head 4 and / or the third shower head 6 to print the base layer (bottom layer) and the structural layer;

[0071] Step 2: When it is necessary to print a circuit (functional layer), start the second nozzle 5 to print a specific circuit (functional layer) on the structural layer;

[0072] Step 3: If the object to be printed is a single-layer structure, go directly to step 4; if it is a multi-layer structure, repeat steps 1 and 2 until the last layer of circuit printing is printed;

[0073] Step 4: Print the topmost structure by using the first spray head 4 and / or the third spray head 6, and complete the printing of the final packaging structure.

[0074] When printing the circuit in step 3, the pause function can also be used to embed electronic components such as sensors, antennas, batteries, and LEDs.

[0075] For the second spray head 5, a...

Embodiment 3

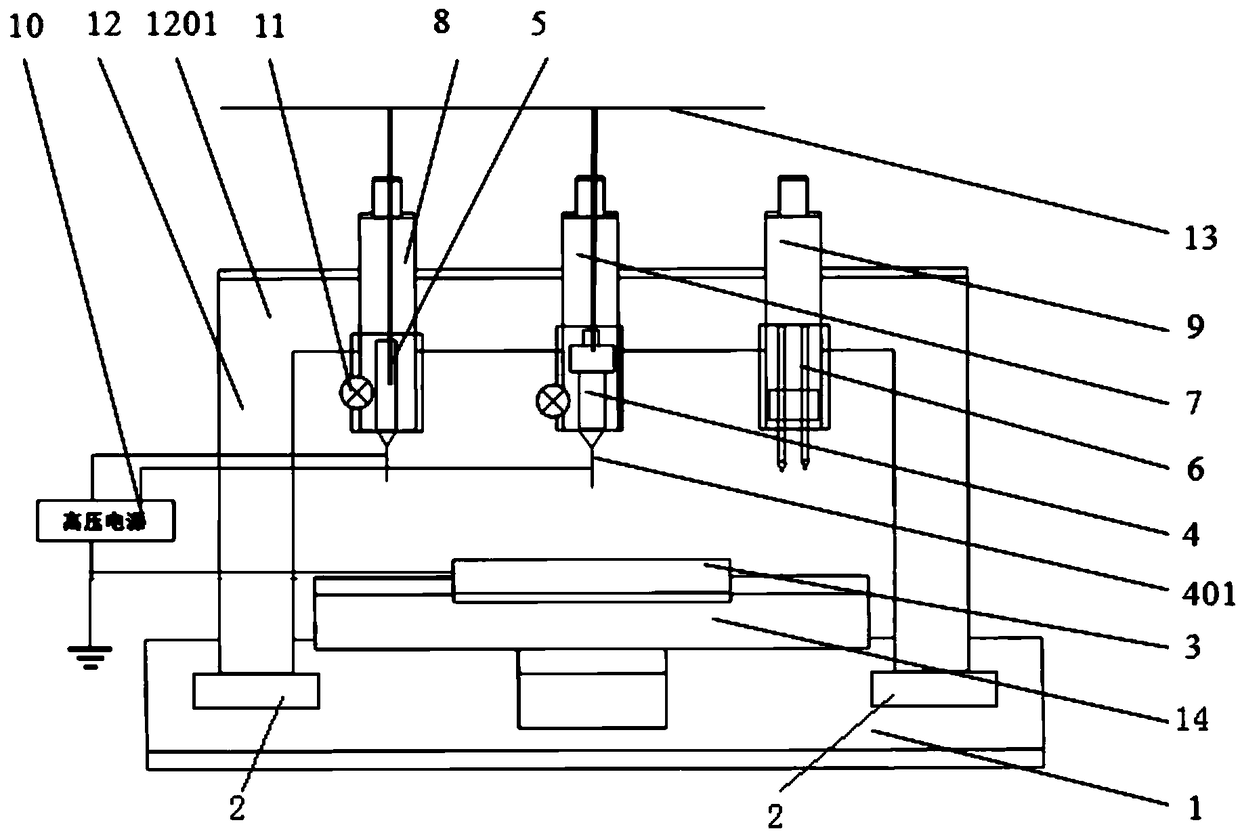

[0079] like image 3 As shown, the multi-material composite 3D printer includes: base 1, x-y workbench 2, print bed 3, first nozzle 4, second nozzle 5, third nozzle 6, z-direction worktable 1 7, z-direction workbench II 8, z direction workbench III 9, high voltage power supply 10, UV curing light source 11, frame 12, pressure pipeline 13, fixed workbench 14. The base 1 is placed at the bottom; the x-y table 2 is placed on the base 1; the printing bed 3 is fixed on the fixed table 14; the fixed table 14 is placed on the base 1; the first nozzle 4 is placed directly above the printing bed 3 , and connected with the z-direction workbench I 7; the z-direction worktable I 7 is fixed on the beam 1201 of the frame 12; the second nozzle 5 is placed above the printing bed 3 and connected with the z-direction workbench II 8; The z-direction workbench II 8 is fixed on the beam 1201 of the frame 12; the third nozzle 6 is placed above the printing bed 3 and connected with the z-direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com