Tool for processing central hole in end part of camshaft

A camshaft and center hole technology, applied in metal processing equipment, metal processing mechanical parts, positioning devices, etc., can solve the problems of inability to accurately control the clamping force, low production efficiency, affecting the force balance of the camshaft, etc. Uncertainty and subjectivity, the effect of improving product processing quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

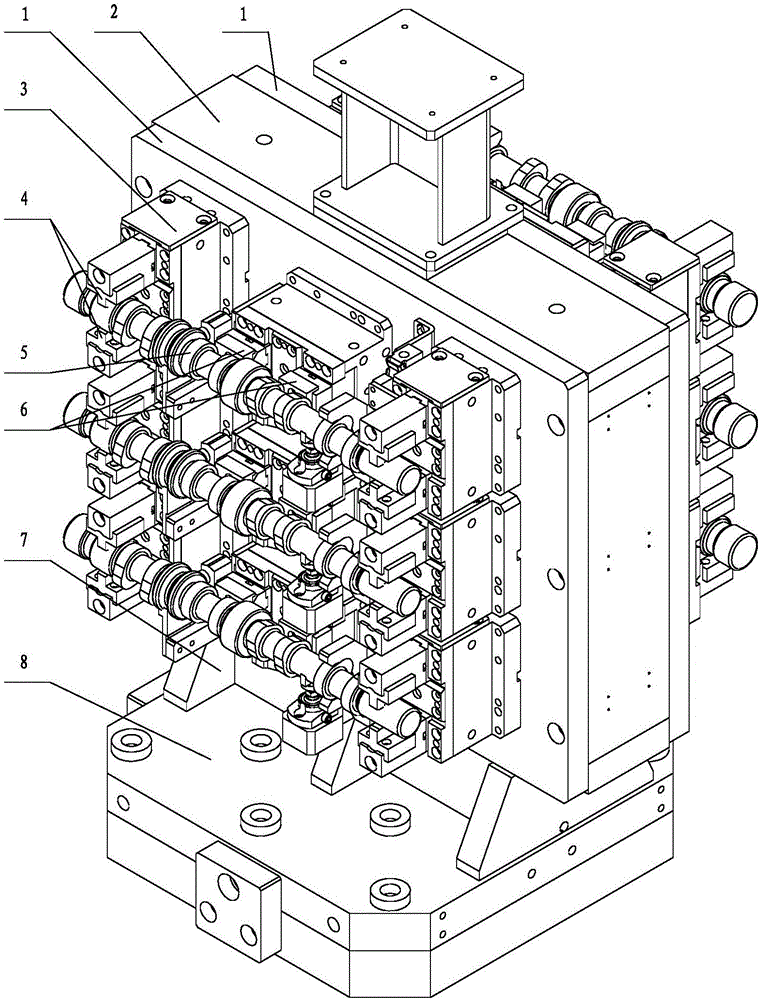

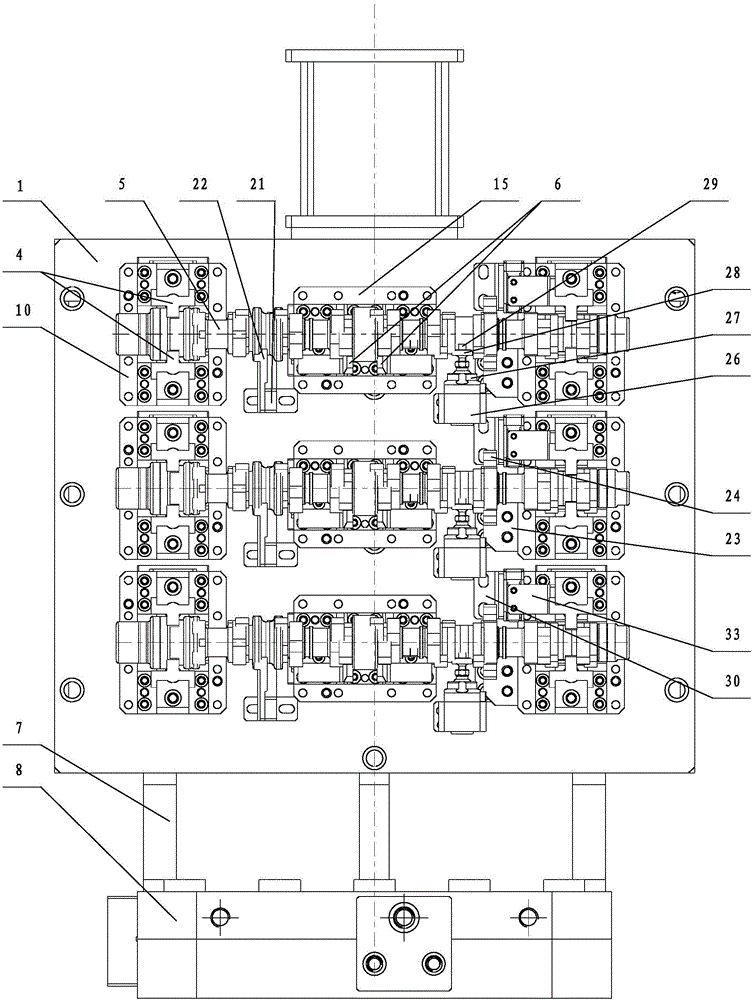

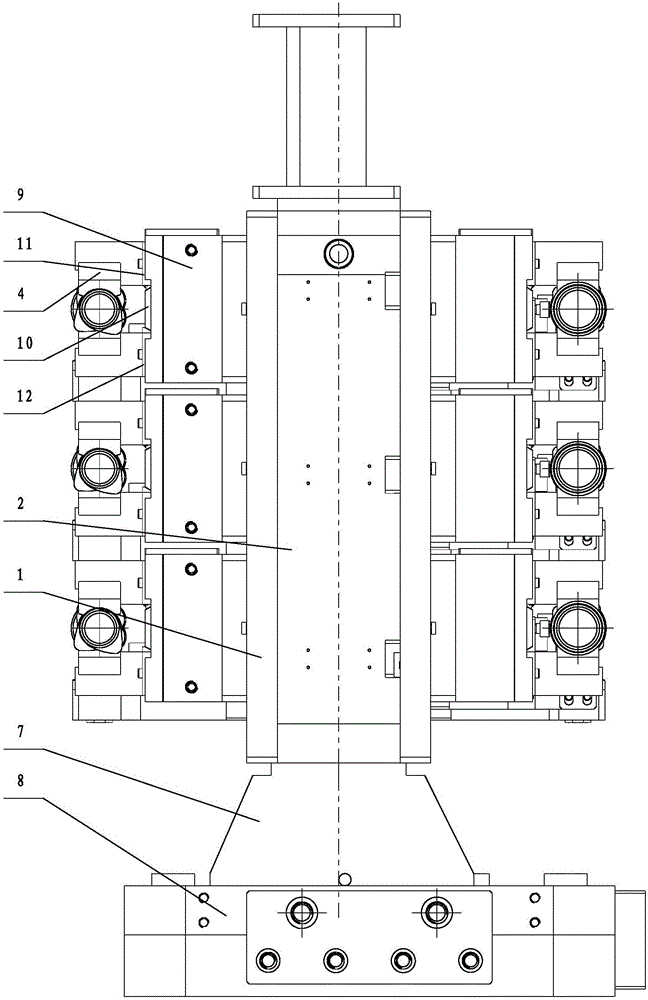

[0030] by Figure 1 ~ Figure 6 The shown structural diagram of the tool for machining the center hole of the camshaft end of the present invention shows that it includes a support frame assembly, a plurality of clamping units 3, a pre-positioning device and a gas inspection device. The lower end of the support frame assembly is connected to the worktable of the machine tool through a rotary cylinder, and each clamping unit 3 clamps and fixes a camshaft 5 and the camshafts 5 are placed horizontally. The plurality of clamping units 3 are arranged in parallel at equal distances from top to bottom and are respectively connected symmetrically on the two end surfaces of the support frame assembly. Each clamping unit 3 is equipped with a pre-positioning device and a gas detection device, and the pre-positioning device and the gas detection device are both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com