Automatic centering guide mechanism and method

A technology of automatic centering and guiding mechanism, applied in the field of mechanical processing, can solve the problems of difficult automatic processing, inaccurate positioning, troublesome loading and unloading work, etc., and achieve the effect of saving time, convenient adjustment and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0034] The embodiment of the present invention provides an automatic centering guide mechanism and method, which solves the problem that each workpiece with different diameters must be individually positioned and clamped when the ordinary steady rest assists in clamping workpieces with different diameters, because the loading and unloading work is troublesome. , It is difficult to be included in automatic processing, and there are problems such as inaccurate orientation and positioning, many transmission points, complex mechanical drive, and high failure rate.

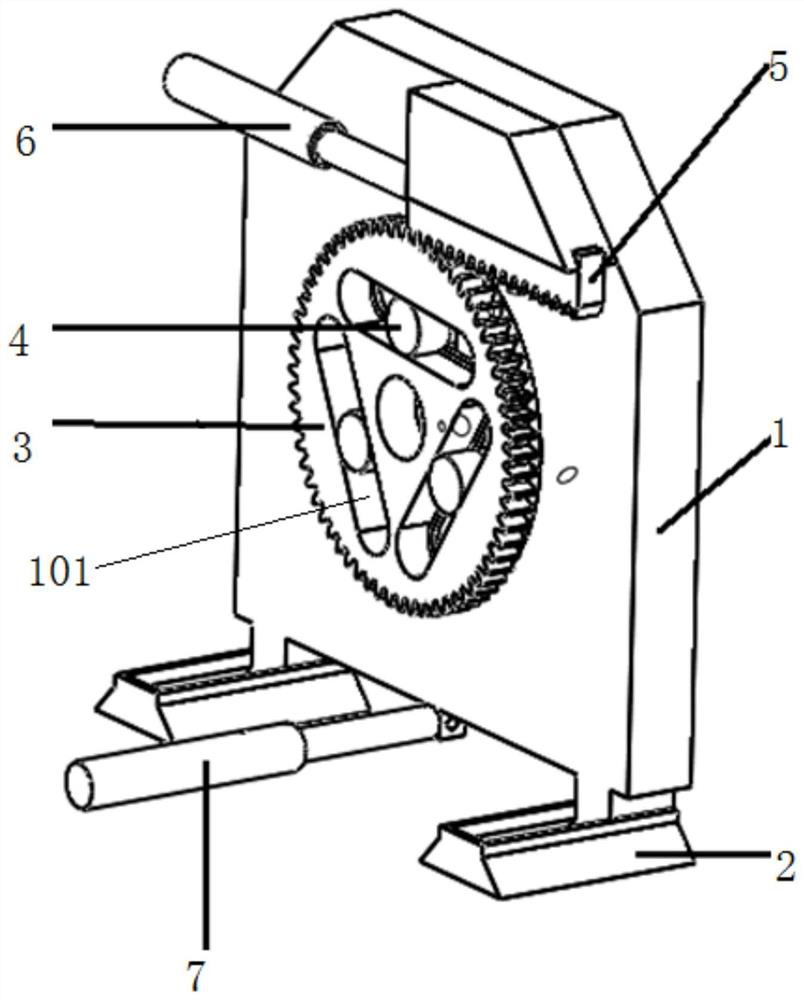

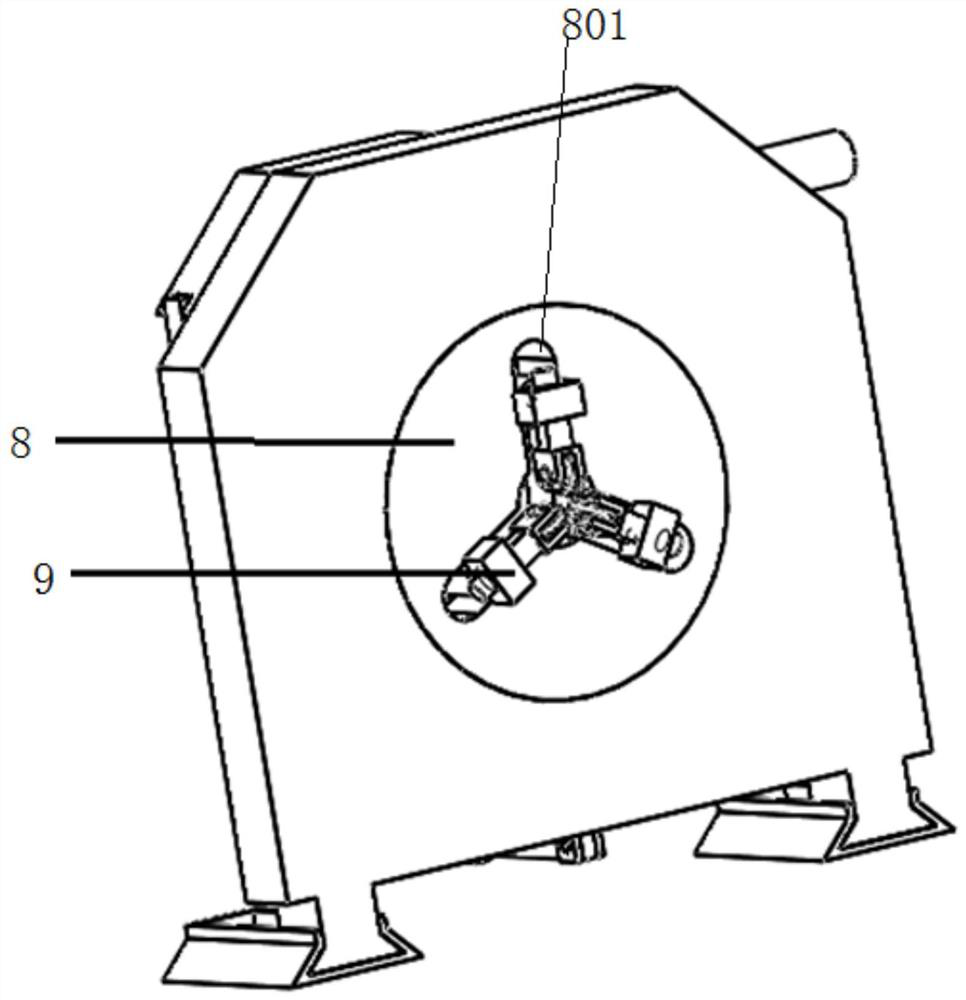

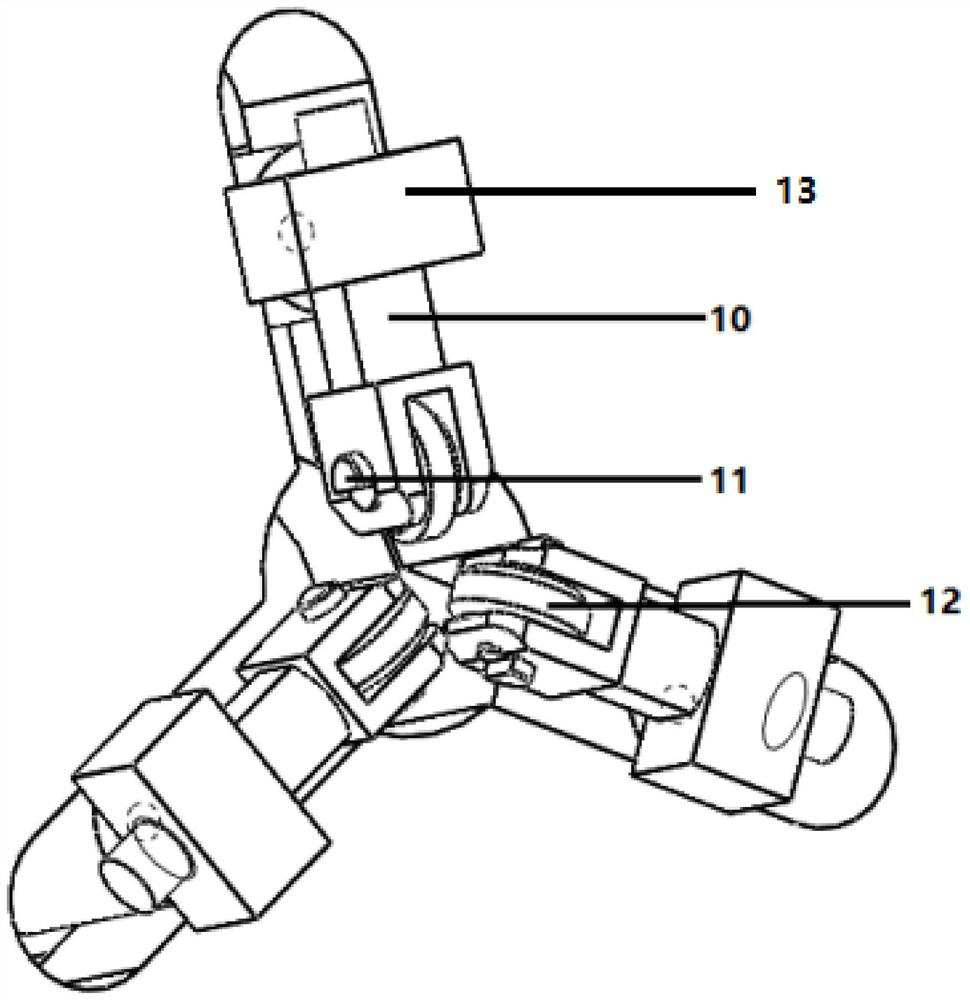

[0035] Such as figure 1 and 2 As shown, an automatic centering guide mechanism includes a base 1 and a rack 5. The center of the base 1 is fixed with a rear disc 8, and the rear disc 8 is connected with a gear disc 3 through a fixed connecting pin 4. Both the rear disc 8 and the gear disc 3 are perfect circles. The gear disc 3 is arranged at the front and the rear disc 8 is arranged at the rear. The centers of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com