Diffusion welding method for stainless steel and Kovar alloy dissimilar metal

A dissimilar metal and stainless steel technology, which is applied in the field of special material connection, can solve the problems of poor welding performance of stainless steel and Kovar alloy, achieve excellent chemical and physical properties, high weld density, and improve tensile performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

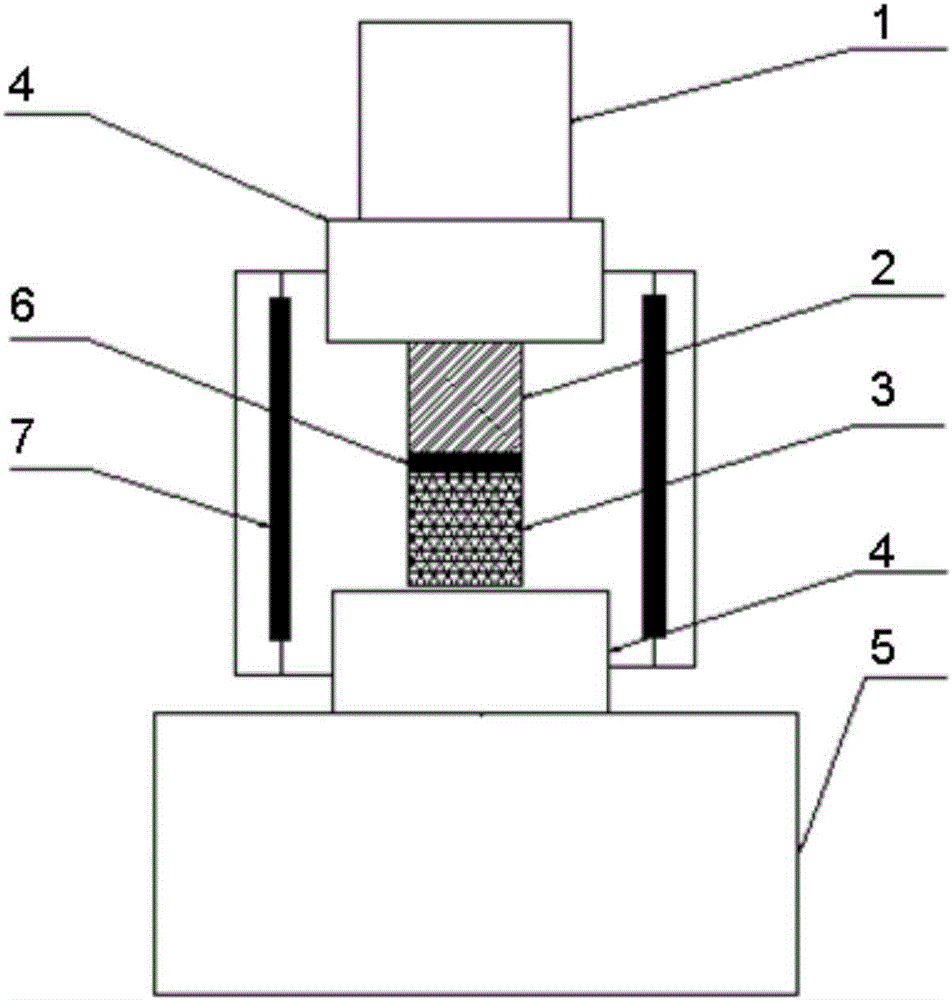

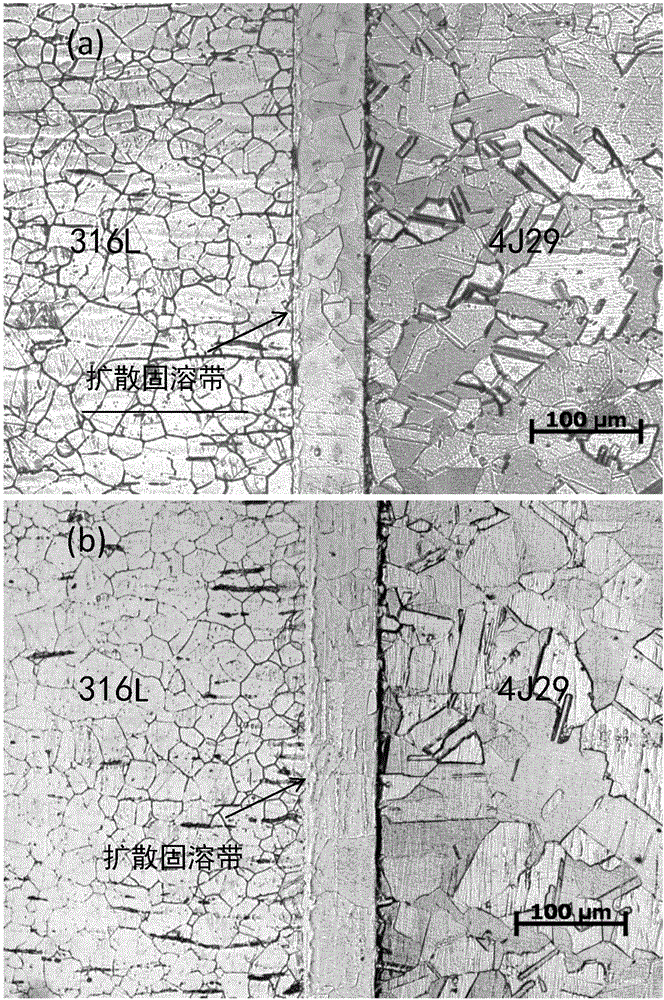

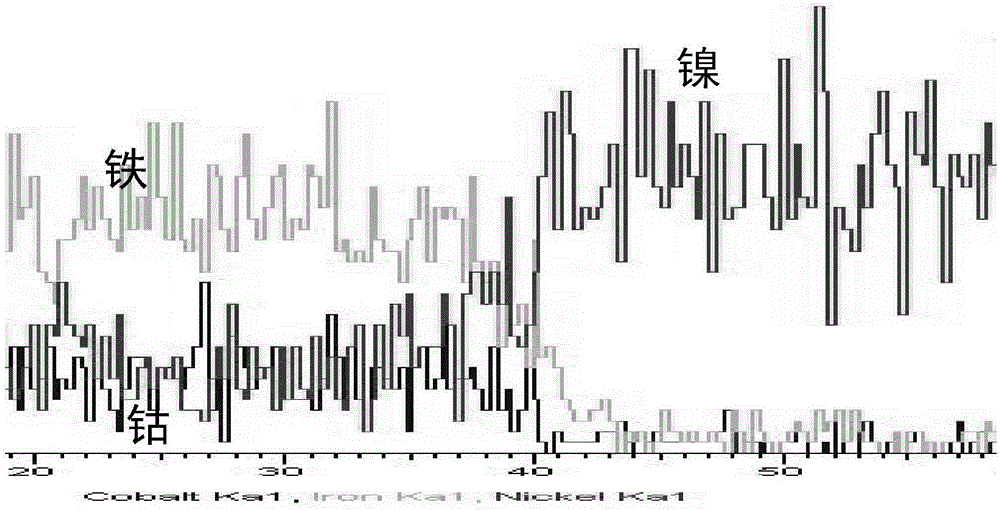

[0032] Grind the surface to be welded of 316L stainless steel and 4J29 Kovar alloy to make the roughness Ra≤2.0μm, put the polished sample and 80μm nickel foil into acetone for 10min ultrasonic cleaning, wipe the surface to be welded with alcohol, and dry it , to obtain cleaned stainless steel, Kovar alloy and nickel foil. Press cleaned stainless steel, Kovar and nickel foils figure 1 stack, use figure 1 The vacuum heat press mechanism shown in . During the pressing process, it is necessary to maintain a good axial neutrality between the sample and the indenter, apply a pre-pressure of 18MPa to the sample to be welded through the upper indenter, and release the pressure; the vacuum hot-press furnace is evacuated to 3×10 -1 Pa; heat up the vacuum hot-press furnace at a rate of 10°C / min. After raising the furnace temperature to 850°C, pressurize to 34.66MPa, hold the heat for 2 hours for diffusion welding; after the heat preservation is over, release the pressure and cool slow...

Embodiment 2

[0034] Grind the surface of 316L stainless steel and 4J29 Kovar alloy to be welded to make the roughness Ra≤2.0μm, put the polished sample and 70μm nickel foil into acetone for 15min ultrasonic cleaning, wipe the surface to be welded with alcohol, and blow it with cold wind Dry to obtain cleaned stainless steel, Kovar and nickel foils. Press cleaned stainless steel, Kovar and nickel foils figure 1 Stacking (nickel foil sandwiched between the two), it is necessary to maintain good axial neutrality between the sample and the indenter, apply a pre-pressure of 20MPa to the sample to be welded through the upper indenter, and release the pressure; Vacuum to 2~5×10 -1 Pa; heat up the vacuum hot-press furnace at a rate of 10°C / min. After raising the furnace temperature to 900°C, pressurize to 34.66MPa, keep the heat for 3 hours for diffusion welding; after the heat preservation is over, release the pressure and cool slowly , the slow cooling rate is 5°C / min, and the slow cooling end...

Embodiment 3

[0052] The same process as in Example 2 is used to weld stainless steel and Kovar alloy. The difference is that a plurality of nickel foils with different thicknesses are used. For the effect of diffusion welding between stainless steel and Kovar, the results are as follows.

[0053] Table 3 Mechanical Properties of Stainless Steel / Kovar Alloy Welded Parts

[0054] sample Tensile strength (MPa) Elongation(%) Fracture location Example 2 (70μm) 501.84 38.75 4J29 Example 3 (40μm) 371.01 12.36 welding interface Example 3 (80μm) 485.54 37.44 4J29 Example 3 (100μm) 450.68 26.25 Interface / 4J29 Example 3 (130μm) 251.27 13.37 welding interface

[0055] From the situation recorded in Table 3, it can be seen that when the welding scheme of stainless steel and Kovar alloy of the present invention is used for welding connection, the thickness selection of nickel foil has a great influence on the mechanical properties of the wel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com