Induction brazing device and method for producing metallurgical composite tubes in atmospheric environment

A technology for atmospheric environment and production metallurgy, applied in the field of steel pipe manufacturing, can solve the problems of complex manufacturing process and high equipment investment cost, and achieve the effects of high base-lining bonding strength, high production efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

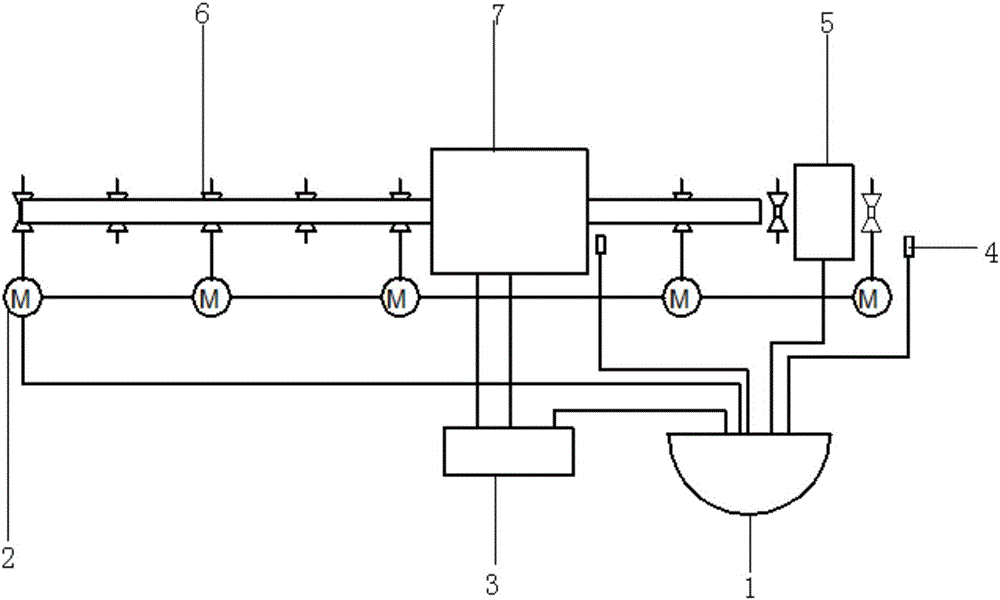

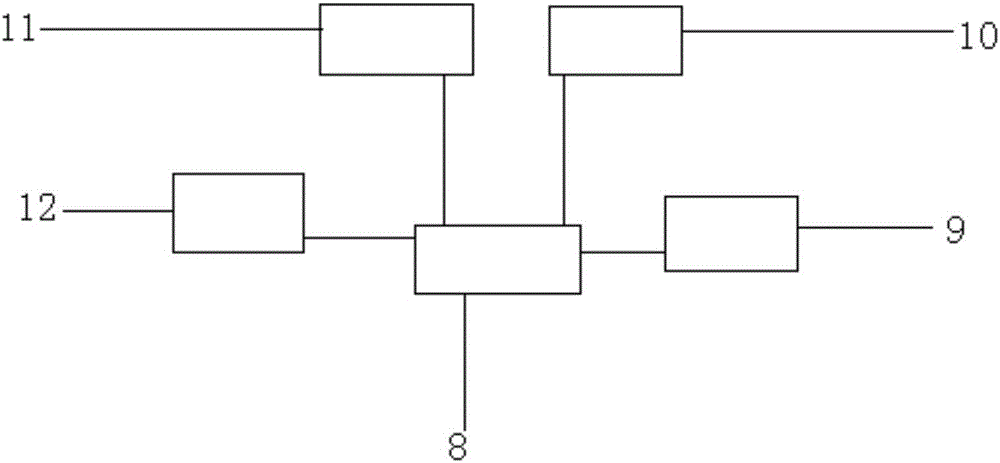

[0032] Braze the mechanical composite pipe made of (45#+304) into a metallurgical composite pipe, the specification is 60×(5+1):

[0033] Clean the inner surface of the base pipe and the inner and outer surfaces of the liner separately. A layer of tin-lead solder is wound on the outer surface of the liner, and the solder is required to be tightly and evenly covered on the outer surface of the liner without overlapping or gaps. Assemble the base pipe and the liner, with the base pipe outside and the liner inside. The base pipe and the liner pipe are composited by a mechanical composite method to obtain a mechanical metal composite pipe, and the mechanical composite pipe is mechanically straightened. Cut off the redundant part protruding from the liner at both ends of the mechanical composite pipe. In the atmospheric environment, let the mechanical composite tube containing brazing material pass through the induction brazing furnace at a constant speed, and the tube body trave...

Embodiment 2

[0036] Braze the mechanical composite pipe made of (20#+316L) into a metallurgical composite pipe, the specification is 114×(10+2):

[0037] Clean the inner surface of the base pipe and the inner and outer surfaces of the liner separately. A layer of copper-based solder is wound on the outer surface of the liner, and the solder is required to be tightly and evenly covered on the outer surface of the liner without overlapping or gaps. Assemble the base pipe and the liner, with the base pipe outside and the liner inside. The base pipe and the liner pipe are composited by a mechanical composite method to obtain a mechanical metal composite pipe, and the mechanical composite pipe is mechanically straightened. Cut off the redundant part protruding from the liner at both ends of the mechanical composite pipe. In the atmospheric environment, let the mechanical composite tube containing the solder pass through the induction brazing furnace at a constant speed, the speed is about 0.4...

Embodiment 3

[0040] Braze the mechanical composite pipe made of L360QS+825 into a metallurgical composite pipe, the specification is 89×(6+1.5):

[0041]Clean the inner surface of the base pipe and the inner and outer surfaces of the liner separately. A layer of nickel-based solder is wound on the outer surface of the liner, and the solder is required to be tightly and evenly covered on the outer surface of the liner without overlapping or gaps. Assemble the base pipe and the liner, with the base pipe outside and the liner inside. The base pipe and the liner pipe are composited by a mechanical composite method to obtain a mechanical metal composite pipe, and the mechanical composite pipe is mechanically straightened. Cut off the redundant part protruding from the liner at both ends of the mechanical composite pipe. In the atmospheric environment, let the mechanical composite tube containing the brazing material pass through the induction brazing furnace at a constant speed, and the runni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com