Photovoltaic junction box copper-clad aluminum current-conducting plate and precision rolling compound method thereof

A technology of volt junction box and copper clad aluminum is applied in the field of photovoltaic junction box copper clad aluminum conductive plate and its finish rolling compound, which can solve the problems of incapable of continuous large-area compounding, low degree of mechanization, unstable quality, etc., and achieve industrial application. Good prospects, meet the comprehensive performance requirements, the effect of small specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0019] refer to Figure 1 to Figure 3 As shown, the finishing rolling composite method of a copper-clad aluminum conductive plate of a photovoltaic junction box of the present invention is mainly as follows:

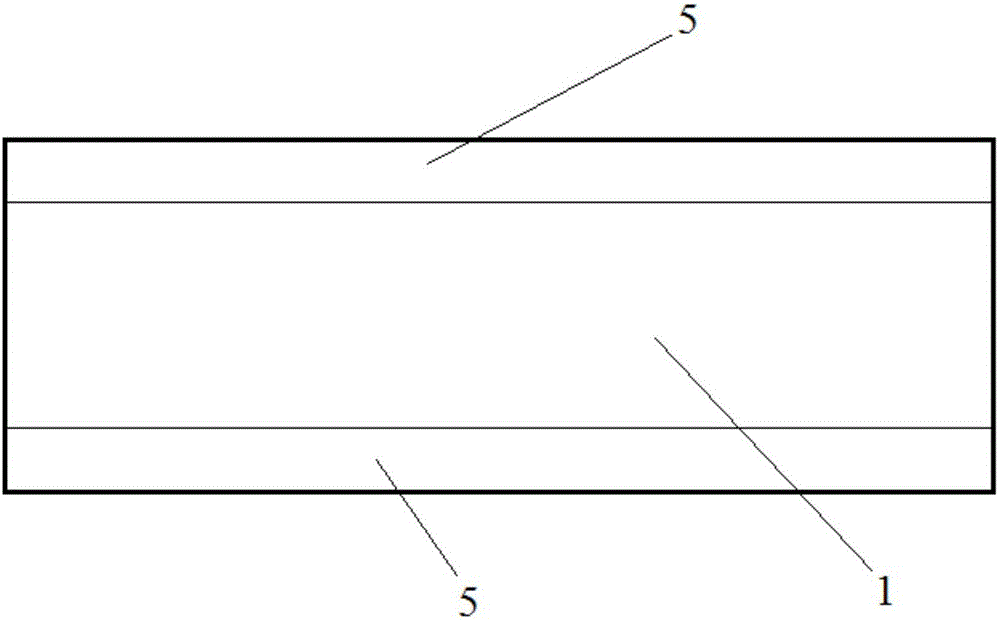

[0020] Select pure copper-pure aluminum-pure copper three-layer composite board (that is, the upper pure copper layer 5-the middle pure aluminum layer 1 and the lower pure copper layer 5, its structure is as follows figure 1 shown) as a rolling substrate, the thickness of the substrate is 2mm, and the thickness ratio of the single-sided pure copper surface layer to the pure aluminum middle layer is 1:6 (that is, the volume ratio of aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com