A kind of nitrogen, sulfur co-doped silica gel immobilized tio2 photocatalyst and preparation method thereof

A photocatalyst and co-doping technology, applied in the field of photocatalytic materials, can solve the problems of less energy to achieve effective doping, and achieve the effects of fine crystallization, firm immobilization, and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

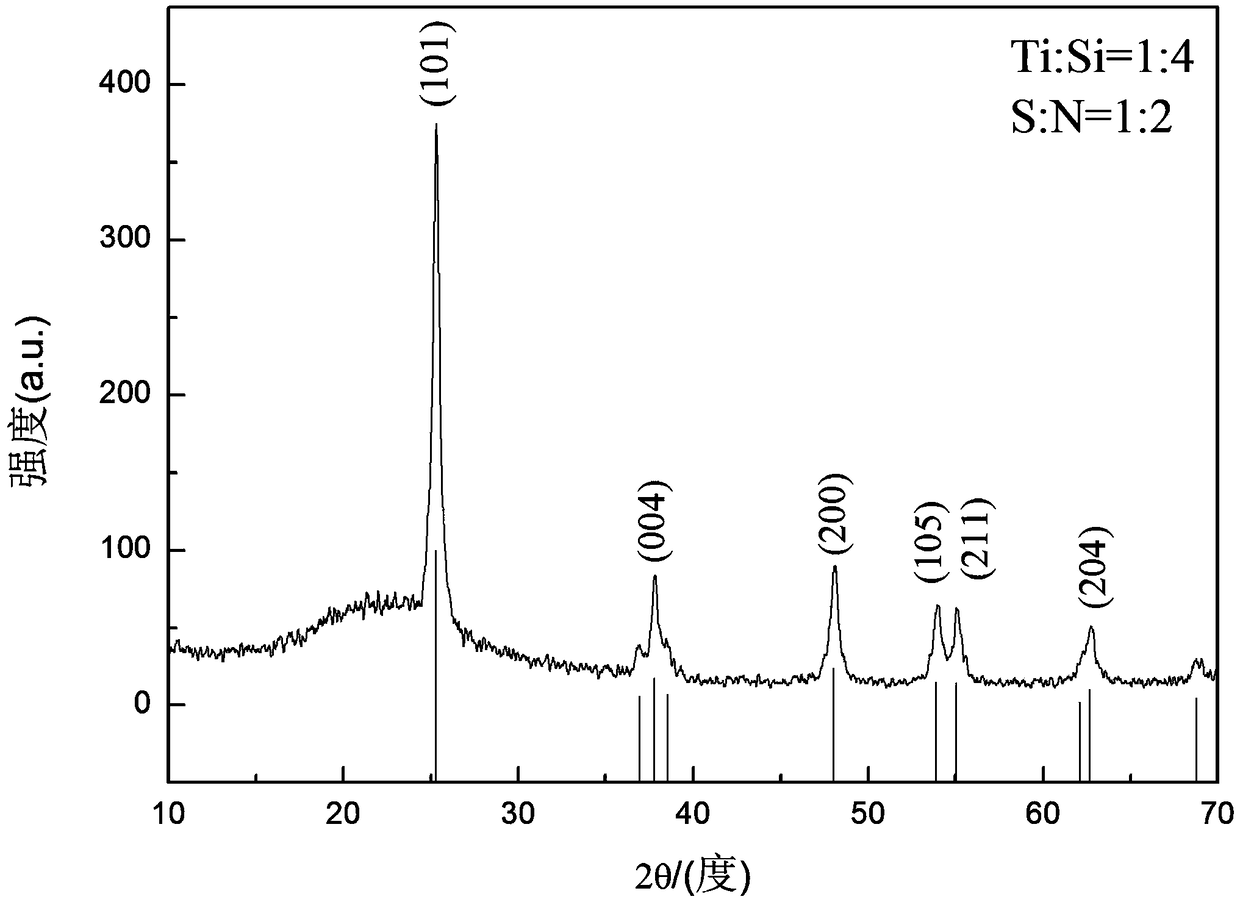

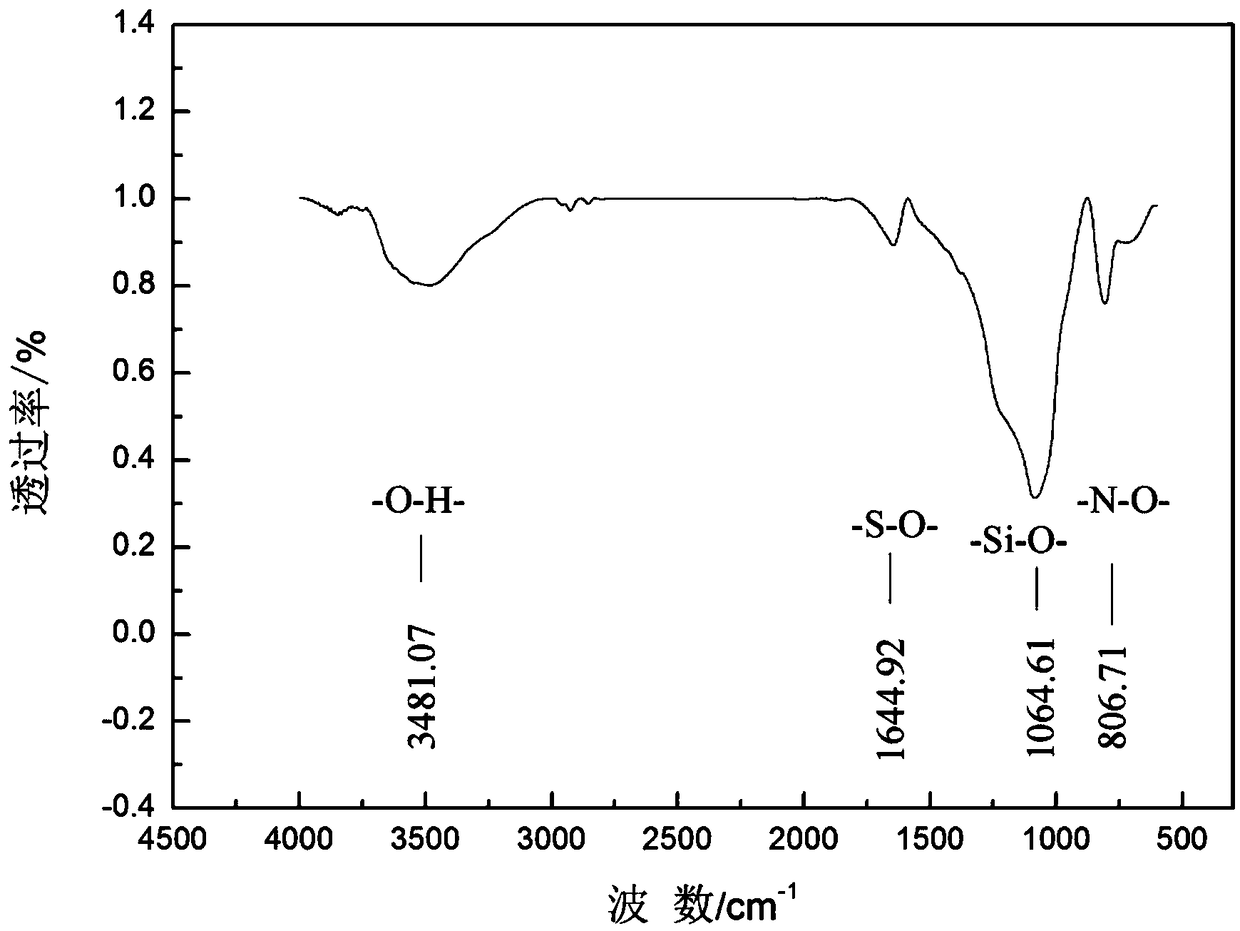

[0033] 1) Measure butyl titanate and ethyl orthosilicate respectively according to the molar ratio n(Ti):n(Si)=1:4, and then add a certain amount of ethanol under continuous stirring respectively to make a solution; then follow Molar ratio n(S): n(N)=1:2 Mixing ratio Measure concentrated sulfuric acid and concentrated nitric acid respectively, use deionized water to make a mixed acid solution with a mass concentration of 19% under continuous stirring;

[0034] 2) Put the tetraethyl orthosilicate solution in a magnetically stirred constant temperature water bath, add the butyl titanate solution dropwise under continuous stirring and a 60°C constant temperature water bath, continue stirring for 10 minutes, and then add the solution according to the molar doping ratio n (Ti): n (S, N) = 1: 0.08 Add the mixed acid solution drop by drop, and continue magnetic stirring for 20 minutes to obtain the copolymer sol;

[0035] 3) Continue to stand the copolymer sol in a constant temperatu...

Embodiment 2

[0039] 1) Measure butyl titanate and ethyl orthosilicate respectively according to the molar ratio n(Ti):n(Si)=1:3, and then add a certain amount of ethanol under continuous stirring to make a solution; then follow Molar ratio n(S):n(N)=1:1 Mixing ratio Measure concentrated sulfuric acid and concentrated nitric acid respectively, and use deionized water to make a mixed acid solution with a mass concentration of 20% under continuous stirring;

[0040] 2) Put the ethyl orthosilicate solution in a magnetically stirred constant temperature water bath, add the butyl titanate solution dropwise under continuous stirring and a 50°C constant temperature water bath, continue stirring for 5 minutes, and then add the solution according to the molar doping ratio n (Ti): n(S, N)=1:0.1 Measured mixed acid solution was added dropwise, and magnetic stirring was continued for 15 minutes to obtain copolymer sol;

[0041] 3) Continue to stand and age the copolymer sol at room temperature for 24 h...

Embodiment 3

[0045] 1) Measure butyl titanate and ethyl orthosilicate respectively according to the molar ratio n(Ti):n(Si)=1:2, and then add a certain amount of ethanol under continuous stirring respectively to make a solution; then follow Molar ratio n(S):n(N)=1:1.2 The mixing ratio is to measure concentrated sulfuric acid and concentrated nitric acid respectively, and use deionized water to make a mixed acid solution with a mass concentration of 18% under continuous stirring;

[0046] 2) Put the ethyl orthosilicate solution in a magnetically stirred constant temperature water bath, add the butyl titanate solution dropwise under continuous stirring and a 55°C constant temperature water bath, continue stirring for 8 minutes, and then add the solution according to the molar doping ratio n (Ti): n (S, N) = 1: 0.05 The measured mixed acid solution was added dropwise, and magnetic stirring was continued for 10 minutes to obtain the copolymer sol;

[0047] 3) Continue to stand the copolymer so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com